Peel-off type anti-fake safety bottle cap

A tear-off and safe technology, applied in the field of bottle caps, can solve the problems of top teeth, scraps, prone to top teeth, and troublesome assembly, etc., and achieves the effect of reducing time, not easy to pull scraps, and reducing cost investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

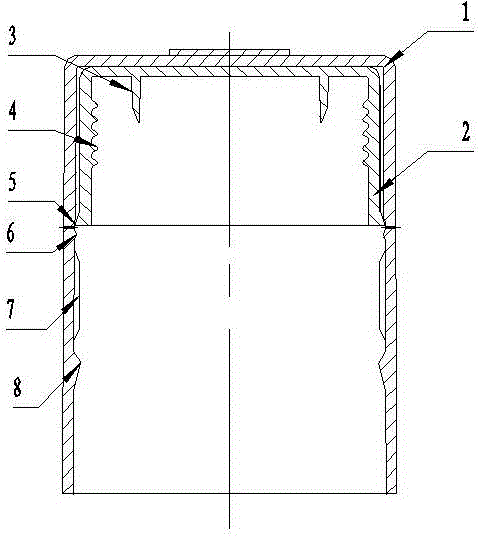

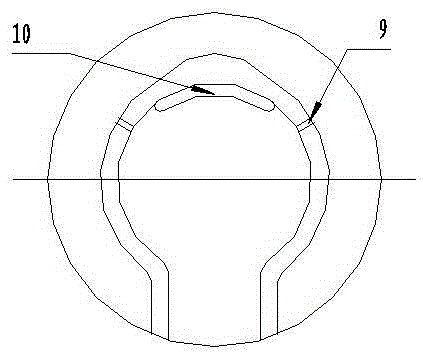

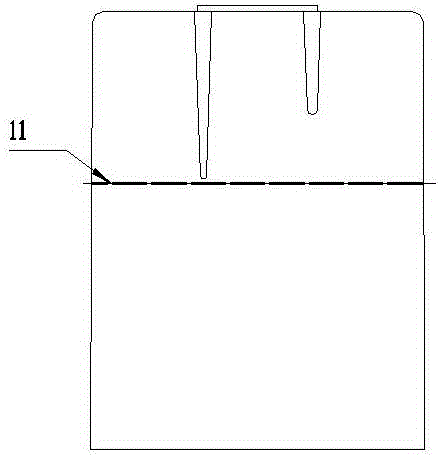

[0011] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the tear-off anti-counterfeit safety bottle cap includes an outer cover 1 and an inner cover 2, the inner cover 2 is embedded in the outer cover 1, and the upper part of the outer cover 1 is provided with Top cover 10, two connection points 9 are arranged between the top cover 10 and the outer cover 1, the side of the outer cover 1 is provided with connection points 11, the barb 8 of the outer cover 1 is in interference fit with the bottle mouth, and the protrusion of the outer cover 1 The convex end surface of the edge 6 is interference fit with the lower end surface 5 of the inner cap 2, the anti-rotation gear 7 of the outer cap 1 cooperates with the anti-rotation gear of the bottle mouth, the thread 4 of the inner cap 2 cooperates with the bottle mouth thread, and the sealing of the inner cap 2 Surface 3 has an interference...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap