A kind of amino acid-containing copper-based nutritional protection agent and preparation method thereof

A copper-based nutrition and amino acid technology, applied in the direction of substrate fertilizer, nitrogen fertilizer, fertilizer mixture, etc., to achieve good effect, good economic and social benefits, and promote the recovery of normal physiological functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

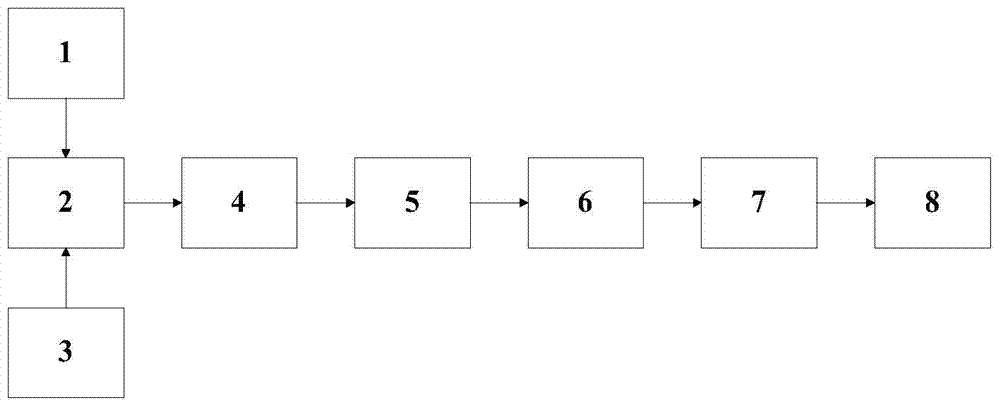

[0025] Weigh 5kg of copper sulfate pentahydrate (1); slowly add it to 6.5L of ammonia water with a concentration of 25%, stir continuously to dissolve it completely, and form a copper coordination complex solution, the reaction time is 20-30min (2); Then add 10L of 5mol / L sodium hydroxide solution in the form of spray droplets for 70-90 minutes, so that the average particle size of the generated copper hydroxide colloid is less than 5 μm (3); then wash the hydroxide with tap water Copper colloidal suspension 3-4 times to make the pH value reach 7.5±0.5, and remove the supernatant by standing or centrifuging to obtain copper hydroxide colloidal suspension (4); dry naturally or in an oven at a temperature lower than 45°C Dry in medium to obtain copper hydroxide colloidal powder (5); take copper hydroxide colloidal powder 300g, add compound amino acid 160g wherein, add dispersant D-425 (alkyl naphthalene sulfonic acid condensation polymer sodium salt) 15g, dispersant SPR (mixture...

Embodiment 2

[0028]Weigh 5kg of copper sulfate pentahydrate (1); slowly add it to 6.5L of ammonia water with a concentration of 25%, stir continuously to dissolve it completely, and form a copper coordination complex solution, the reaction time is 20-30min (2); Then add 10L of 5mol / L sodium hydroxide solution in the form of spray droplets for 70-90 minutes, so that the average particle size of the generated copper hydroxide colloid is less than 5 μm (3); then wash the hydroxide with tap water Copper colloidal suspension 3-4 times to make the pH value reach 7.5±0.5, and remove the supernatant by standing or centrifuging to obtain copper hydroxide colloidal suspension (4); dry naturally or in an oven at a temperature lower than 45°C Dry in medium to obtain copper hydroxide colloidal powder (5); take copper hydroxide colloidal powder 300g, add compound amino acid 160g wherein, add dispersant D-425 (alkyl naphthalene sulfonic acid condensation polymer sodium salt) 15g, dispersant SPR (mixture ...

Embodiment 3

[0031] The addition process is the same as in Example 1, but there are differences in the amino acids added. Such as: add glutamic acid 160g, other processes are with example 1.

[0032] In the obtained suspension concentrate: by dry basis weight, Cu%==39.18%. The suspension pH of this suspension product is 7.0-8.0 when the spraying concentration is 1:500-1000 after adding water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com