Electroplating method with uniform plating thickness and products thereof

A coating thickness, uniform technology, applied in the direction of coating, circuit, printed circuit, etc., can solve the problem of different current density and achieve the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

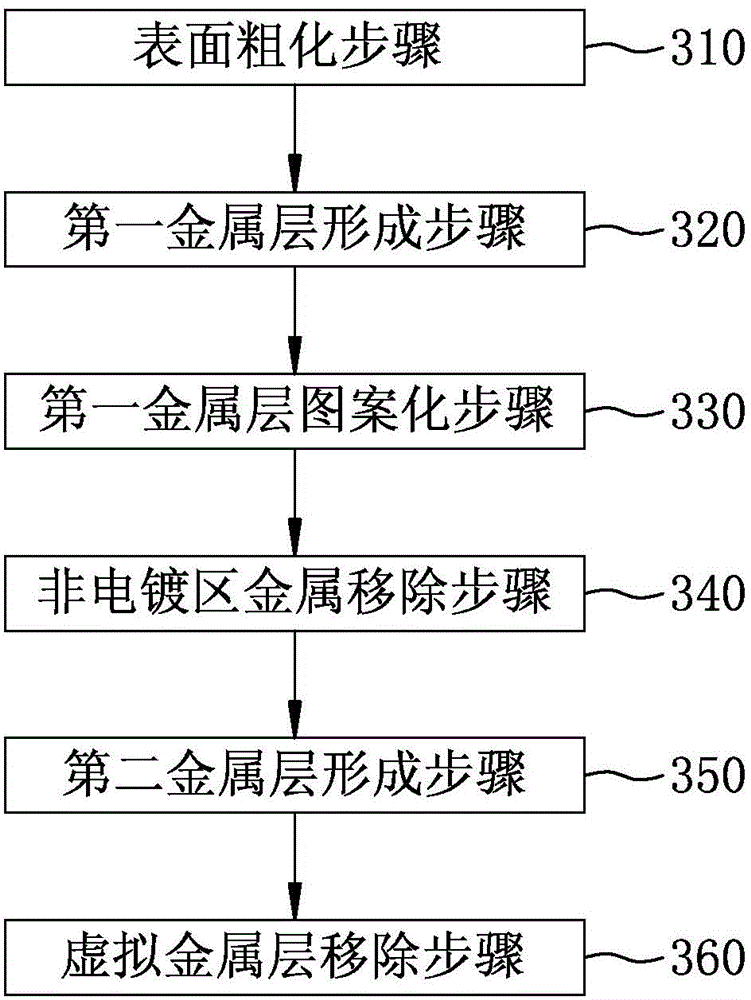

[0027] refer to figure 1 , an embodiment of the electroplating method with uniform metal coating thickness of the present invention, comprising the following steps:

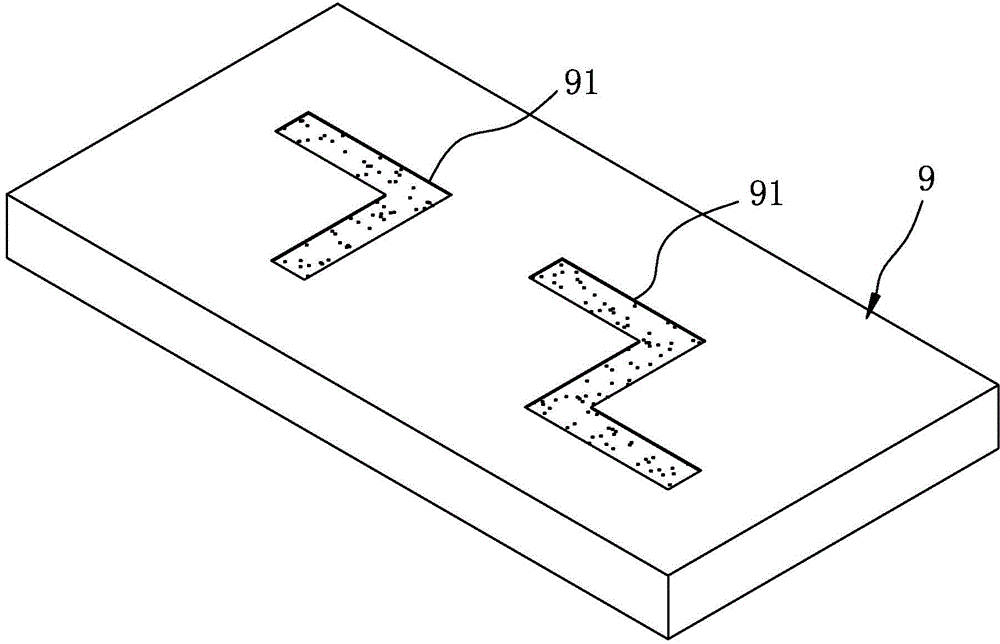

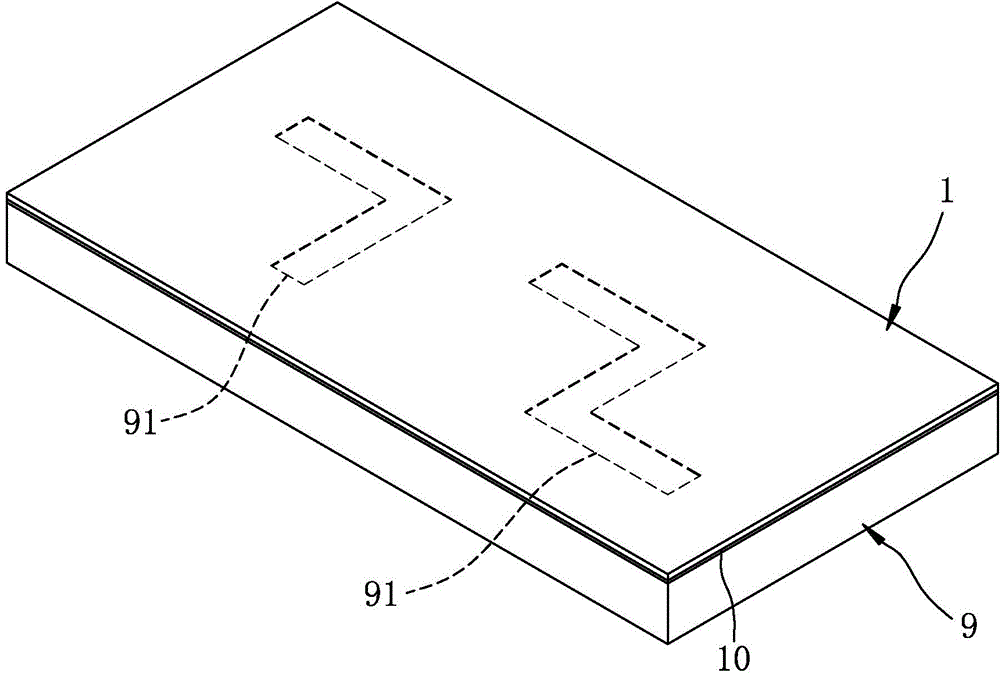

[0028] collocation reference figure 2 , a surface roughening step 310: according to the required electroplating pattern, laser processing is performed on a non-conductive substrate 9, so that most of the actual electroplating pattern areas formed by laser ablation are formed on the surface of the non-conductive substrate 9 91. The laser includes but not limited to infrared pulse laser and green pulse laser, the power of which can be between 6.0-13.0W, and the pulse frequency can be between 5.0-30.0kHz. The surface of each actual electroplating pattern area 91 has a microstructure, which can increase the roughness of the surface of the non-conductive substrate 9 and improve the adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com