Ejector pin for mechanical speed sensor

A technology of mechanical speed and sensors, which is applied in the direction of equipment, instruments, speed/acceleration/impact measurement with unique mechanical means, and can solve the problems of low service life, large wear of the spherical surface of the thimble and the ball socket of the thimble seat, and large contact stress of the spherical surface of the thimble. And other problems, to achieve the effect of prolonging the service life, prolonging the service life and reducing frictional heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

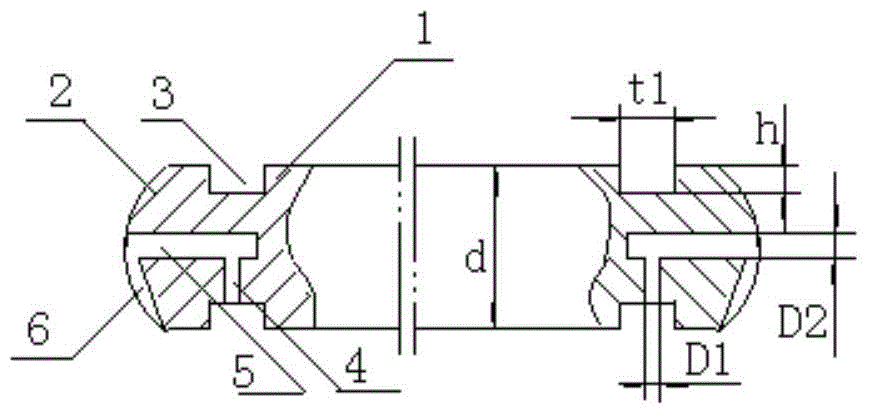

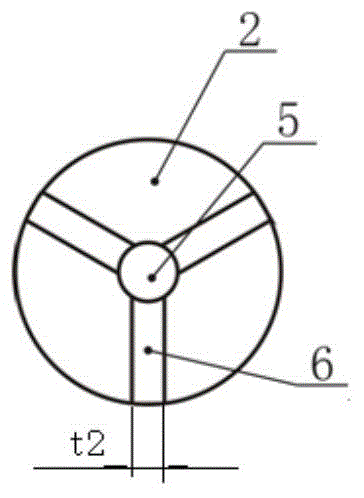

[0013] Example 1, the thimble of a certain type of mechanical speed sensor, its main structural parameters are: d=4.5mm, h=0.75mm, t1=2.5mm, t2=0.5mm, n=3, D1=Ф1mm, D2=Ф1mm. Tests have proved that the maximum temperature of the spherical surface of the thimble and the ball socket of the thimble seat in this embodiment is reduced by 22°C from 80°C, and the service life is extended by 2.5 times.

Embodiment 2

[0014] Example 2, the thimble of a certain type of mechanical speed sensor, its main structural parameters are: d=3.5mm, h=0.5mm, t1=1.8mm, t2=0.5mm, n=2, D1=Ф1mm, D2=Ф0. 8mm.

Embodiment 3

[0015] Example 3, the thimble of a certain type of mechanical speed sensor, its main structural parameters are: d=6mm, h=1mm, t1=3mm, t2=0.5mm, n=4, D1=Ф1.5mm, D2=Ф1.2mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com