Printed circuit board and pad surface treatment method for mobile terminal

A technology for printed circuit boards and mobile terminals, applied in the secondary processing of printed circuits, printed circuit parts, electrical connection printed components, etc., can solve the problems of unfavorable finished product yield, long production cycle, high cost, etc., and it is easier to achieve the yield rate Controlling, reducing production cost and time, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

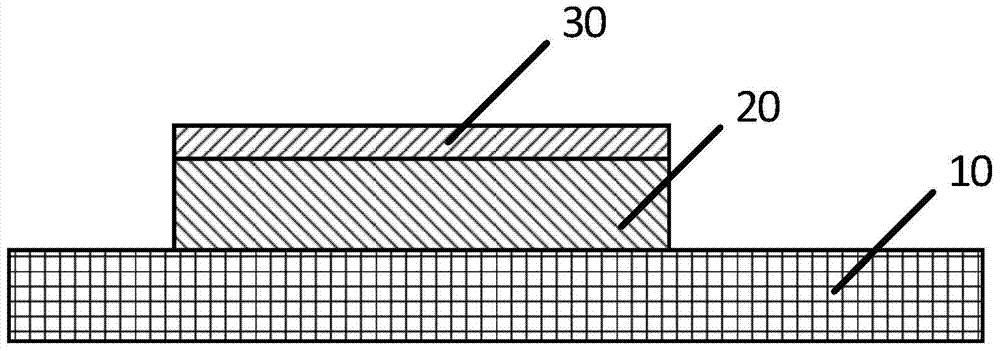

[0023] figure 1 It is a structural schematic diagram of a printed circuit board for a mobile terminal in this embodiment, as figure 1 As shown, the printed circuit board used in the mobile terminal involved in this embodiment includes a printed circuit board 10 and a plurality of solder pads 20, and an organic metal protective layer 30 is disposed on the solder pads.

[0024] The organometallic protective layer 30 is formed by polycondensation of metal alkoxide and organic precursor on the pad surface after alcoholysis. The thickness of the organometallic protective layer is 60-70nm.

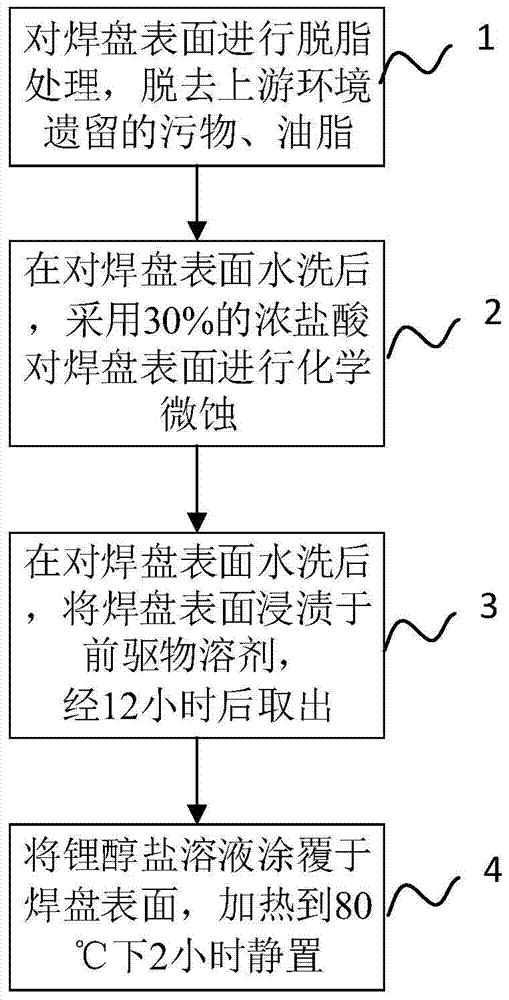

[0025] The principle is to use the sol-gel method. The main reaction process is that the organic and inorganic precursors are dissolved in the co-solvent to form a uniform solution. The reactants produce alcoholysis reaction and then carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com