A Production Process for Preventing "Core Collapse" Defects of Ultra-Thin Steel Coils

A production process and steel coil technology, applied in the direction of manufacturing tools, metal processing equipment, workpiece lubrication devices, etc., can solve the problem of increased sleeve manufacturing and logistics costs, unsatisfactory anti-"collapse core" defects, and production costs of cold-rolled steel enterprises increase and other issues, to achieve the effect of enhancing market competitiveness, eliminating core collapse, and saving manufacturing and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

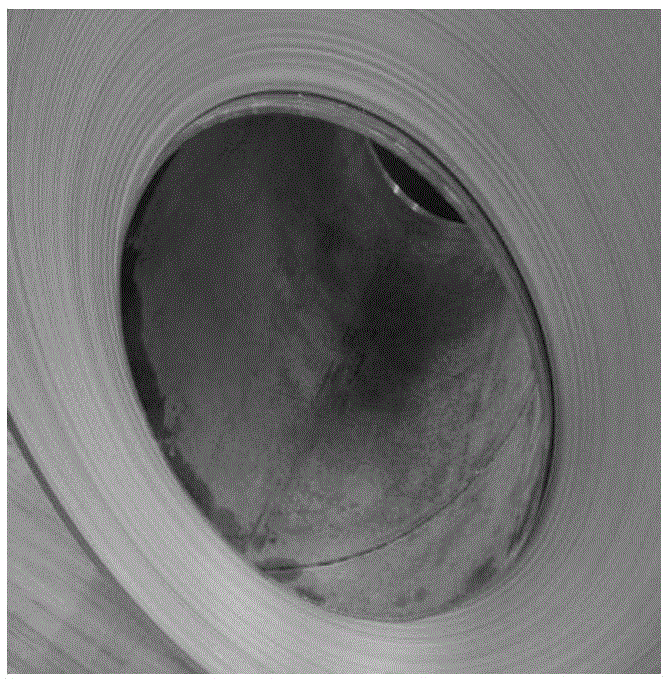

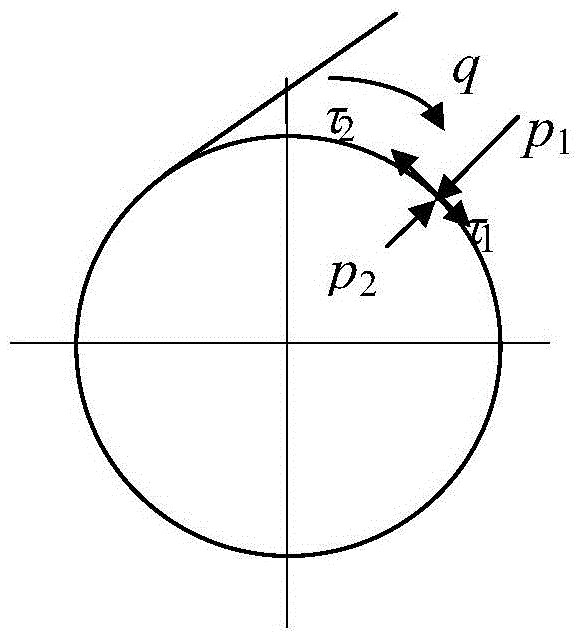

Image

Examples

Embodiment 1

[0030] Embodiment 1 produces the thin-gauge steel coil of 0.25mm thickness

[0031] (1) Raw material preparation: choose hot-rolled coil, thickness 3.0mm, SPHC, width 1250mm, steel coil diameter 1850mm;

[0032] (2) Uncoiling: The raw steel coil is uncoiled by the uncoiler, and the head of the strip passes through the rolling mill and the coiler successively. The jaws of the coiler clamp and coil the strip for 1.5 turns, and establish a large linkage tension of 43.7KN, that is, set 2 times the fixed tension 21.9KN;

[0033] (3) Rolling: After 6 passes of rolling, the following process parameters of each pass use a reduction ratio (%) of 34-32-36-35-34-33, and a rolling force (MN) of 11 -10-11-10-10-9, the tension (KN) system is 140-130-110-85-53-21.9, the rolling speed is not less than 400m / min, and the extreme pressure performance is good in the rolling process Fulton ROLKLEEN AS 2600HD dispersive rolling oil, the operating temperature is controlled at 55-58°C, the concentr...

Embodiment 2

[0038] Embodiment 2 produces the thin-gauge steel coil of 0.22mm thickness

[0039] (1) Raw material preparation: choose hot-rolled coil, thickness 2.75mm, SPHC, width 1000mm, steel coil diameter 1970mm;

[0040] (2) Uncoiling: The raw steel coil is uncoiled by the uncoiler, and the head of the strip passes through the rolling mill and the coiler successively. The jaws of the coiler clamp and coil the strip for 1.5 turns, and establish a linkage high tension of 30.8KN, that is, set 2 times the fixed tension 15.4;

[0041] (3) Rolling: After 6 passes of rolling, the following process parameters of each pass use a reduction ratio (%) of 35-33-35.5-35.5-34.5-33, and a rolling force (MN) of 11- 11-10-10-11-10, Tension (KN) 140-130-105-65-40-15.4, rolling speed not less than 400m / min, Houghton ROLKLEEN with super extreme pressure performance is used in the rolling process AS 2600HD dispersive rolling oil, the temperature is controlled at 55-58°C, the concentration is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com