Working method of casting injection molding mold

A technology of injection molding and working method, applied in the field of molds, can solve problems such as increasing production costs of enterprises, high wages of employees, affecting enterprise benefits, etc., and achieve the effects of reducing production costs, high product precision, and low technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

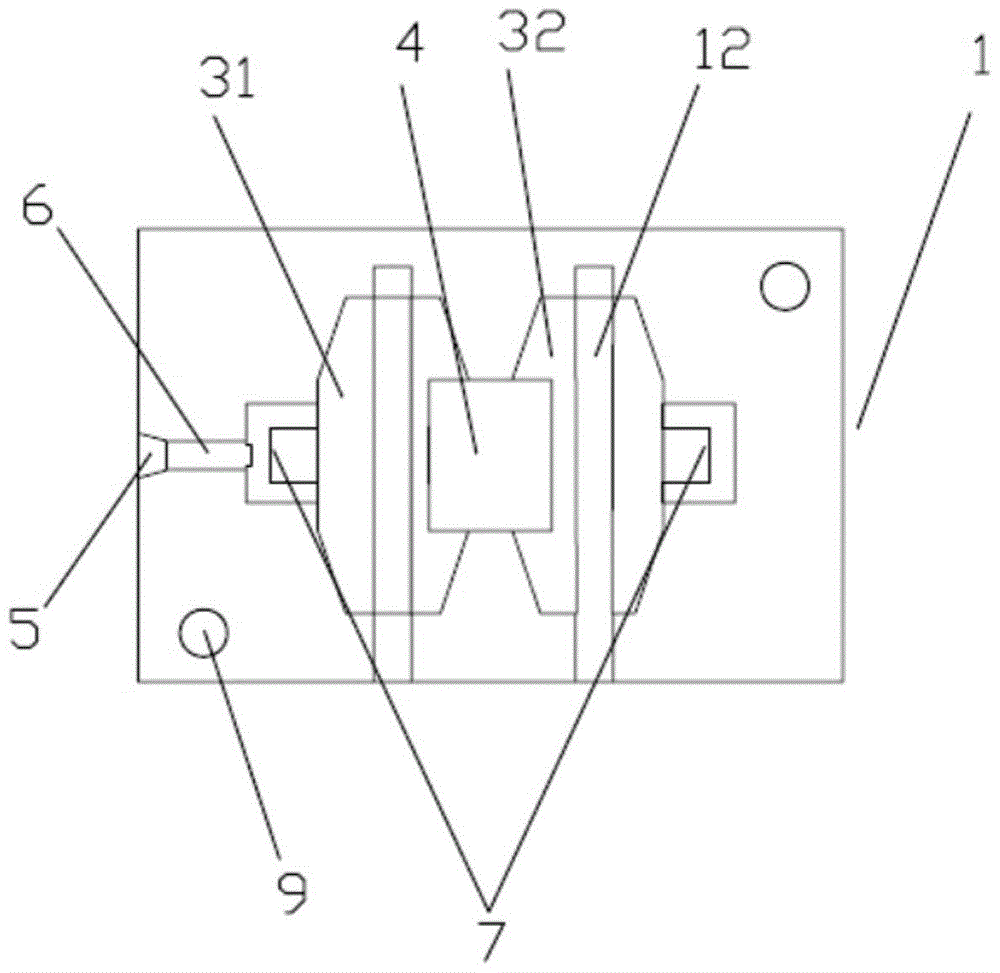

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as Figure 1-2 As shown, an injection molding mold for agricultural machinery castings includes an upper mold 1 and a lower mold 2 . Protrusions 9 and fixing holes 8 are respectively provided on the surfaces of the upper mold 1 and the lower mold 2 , and the protrusions 9 and the fixing holes 8 are connected and fixed in cooperation with each other. The cavity 3 of the injection molding mold includes a first cavity 31 and a second cavity 32, and a stop post 4 is arranged between the first cavity 31 and the second cavity 32, and the stop post 4 is a rod with a groove 41 cylinders. In the first cavity 31 and the second cavity 32, a transverse block 10 is respectively provided along the direction of the transverse centerline of the first cavity 31 and the second cavity 32; Have " concave " type groove 7. The depth of the "concave" groove (7) is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com