Preparation method of graphene ball toughened SiCN ceramic

A technology of graphene spheres and graphene, which is applied in the field of SiCN ceramic preparation, can solve problems such as the complexity of the preparation process, and achieve the effects of simple conditions, high hardness, and improved compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

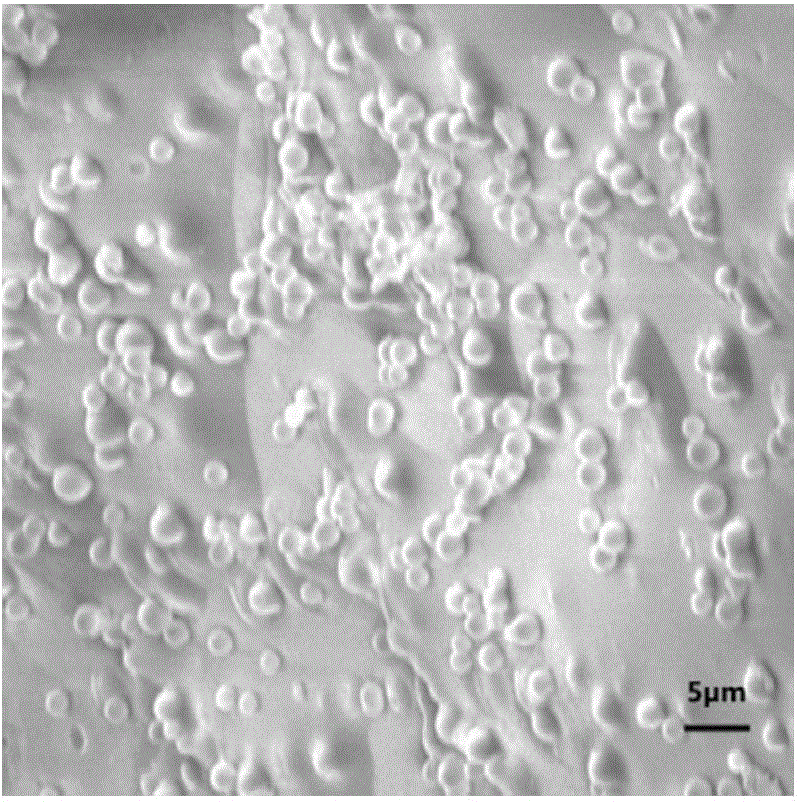

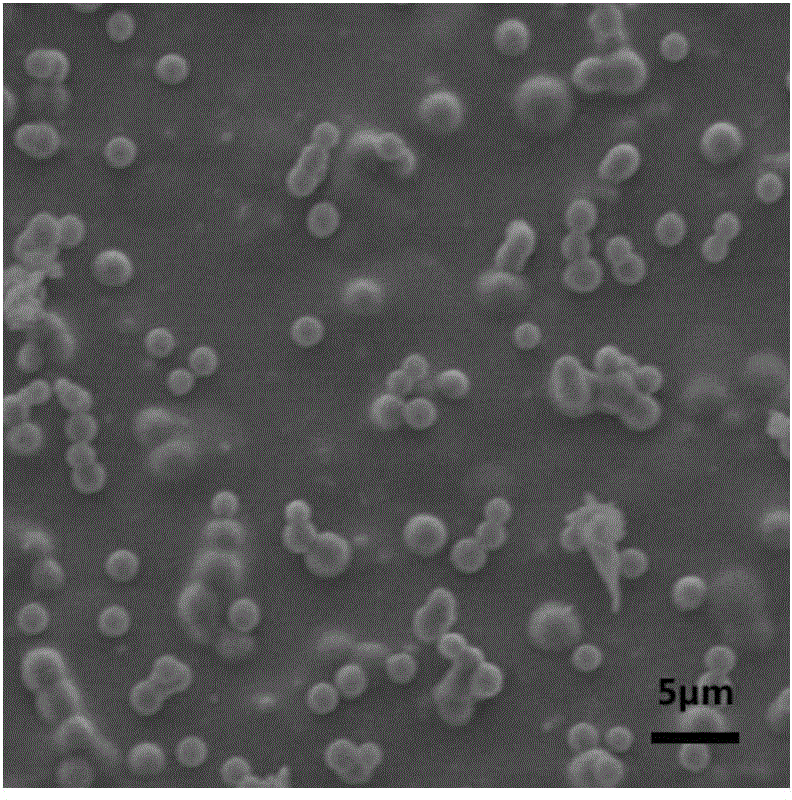

Image

Examples

Embodiment 1

[0022] This embodiment prepares graphene sphere toughened SiCN ceramics, comprising the following steps:

[0023] 1. Ultrasonic clean the beaker twice with deionized water and absolute ethanol respectively, and dry it. Weigh 5 mg of graphene oxide in a beaker with an electronic balance with an accuracy of 0.1 mg. Use a graduated cylinder to measure 5ml of absolute ethanol into the beaker and seal it quickly. Put it into an ultrasonic cleaning machine and sonicate at a power of 220W for 30 minutes to obtain a graphene oxide absolute ethanol dispersion A with a concentration of 1 mg / ml.

[0024] 2. Weigh 3g of polysilazane in a beaker with an electronic balance, measure 1ml of dispersion A with a measuring cylinder and add it to the polysilazane liquid, stir for 30min to obtain mixed solution B.

[0025] 3. Add the mixed solution B into a container folded with tinfoil, put it into a tube furnace, and cross-link in a nitrogen atmosphere. The crosslinking temperature was 300°C,...

Embodiment 2

[0032] This embodiment prepares graphene sphere toughened SiCN ceramics, comprising the following steps:

[0033] 1. Ultrasonic clean the beaker twice with deionized water and absolute ethanol respectively, and dry it. Weigh 10 mg of graphene oxide into a beaker with an electronic balance with an accuracy of 0.1 mg. Use a graduated cylinder to measure 5ml of absolute ethanol into the beaker and seal it quickly. Put it into an ultrasonic cleaning machine and ultrasonicate at a power of 220W for 30 minutes to obtain a graphene oxide absolute ethanol dispersion A with a concentration of 2 mg / ml.

[0034] 2. Weigh 3g of polysilazane in a beaker with an electronic balance, measure 1ml of dispersion A with a measuring cylinder and add it to the polysilazane liquid, stir for 1 hour, and ultrasonicate for 30 minutes to obtain mixed solution B.

[0035] 3. Add the mixed solution B into a container folded with tinfoil, put it into a tube furnace, and cross-link in a nitrogen atmospher...

Embodiment 3

[0042] This embodiment prepares graphene sphere toughened SiCN ceramics, comprising the following steps:

[0043]1. Ultrasonic clean the beaker twice with deionized water and absolute ethanol respectively, and dry it. Weigh 10 mg of graphene oxide into a beaker with an electronic balance with an accuracy of 0.1 mg. Use a graduated cylinder to measure 5ml of absolute ethanol into the beaker and seal it quickly. Put it into an ultrasonic cleaning machine and ultrasonicate at a power of 220W for 30 minutes to obtain a graphene oxide absolute ethanol dispersion A with a concentration of 2 mg / ml.

[0044] 2. Weigh 3g of polysilazane in a beaker with an electronic balance, measure 1ml of dispersion A with a measuring cylinder and add it to the polysilazane liquid, stir for 1 hour, and ultrasonicate for 30 minutes to obtain mixed solution B.

[0045] 3. Add the mixed solution B into a container folded with tinfoil, put it into a tube furnace, and cross-link in a nitrogen atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com