Method for reducing energy consumption of oxidizing reaction unit of phenol-acetone device

An oxidation reaction, phenol acetone technology, applied in chemical instruments and methods, preparation of oxygen-containing compounds, preparation of peroxy compounds, etc., can solve the problem of high energy consumption, and achieve the effect of increasing pipeline resistance and increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

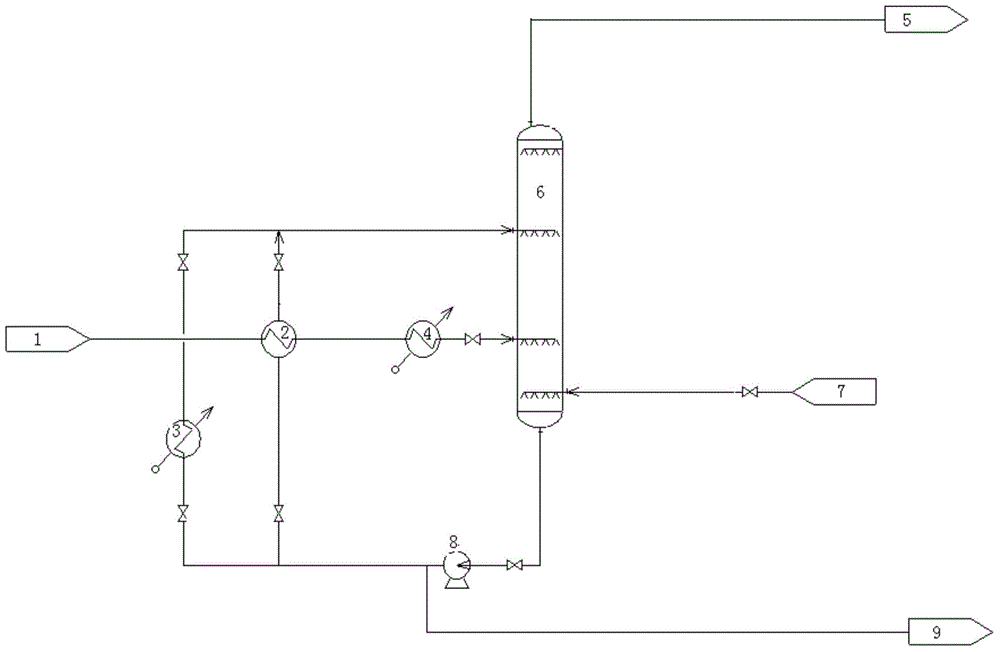

[0019] in such as figure 1 In the shown device flow process, the mass content of cumene is that the cumene raw material feed line (1) of 66.1% carries out heat exchange with the oxidation tower reflux material by the oxidation tower heat exchanger (2), and the heated isopropyl benzene The benzene raw material enters the oxidation tower (6) after being preheated to 55°C by the preheater (4), and undergoes an oxidation reaction with the air introduced through the air inlet line (7); the top of the oxidation tower (6) contains a small amount of cumene The tail gas of water and water is sent to the outside through the gas phase outlet pipeline (5); the liquid phase material containing cumene and cumene hydroperoxide in the tower kettle of the oxidation tower (6) is boosted by a booster pump (8), and a part of the liquid phase The material is sent out as the oxidation product, and a part of the oxidation product (9) enters the oxidation tower heat exchanger (2) through the reflux p...

Embodiment 2

[0025] According to the conditions and steps described in Example 1, the production scale of phenol acetone is changed to 200,000 tons / year. It can reduce the consumption of low-pressure steam by 3.80 tons / hour, and reduce the consumption of circulating cooling water by 203 tons / hour.

Embodiment 3

[0027] According to the conditions and steps described in Example 1, only the production scale of phenol-acetone is changed to 350,000 tons / year. It can reduce the consumption of low-pressure steam by 6.65 tons / hour, and reduce the consumption of circulating cooling water by 354 tons / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com