Underground mine and ore lifting method

An ore and mine technology, applied in the field of ore lifting in underground mines, can solve the problems of serious environmental pollution, uncontinuous production, and high transportation costs, and achieve the effects of reducing environmental pollution, reducing transportation costs, and simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

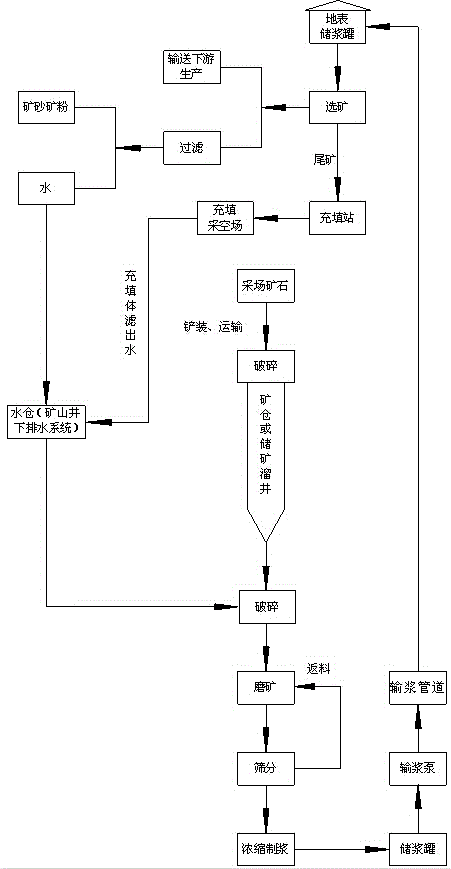

[0026] Such as figure 1 Shown in the figure is an ore lifting method in an underground mine. The ore mined by crushing underground is shoveled and transported to a mine bin or a storage chute to be processed in the next process. The crushed ore is ground underground, and then screened after grinding. The ore with a suitable particle size enters the pulping process, and the unqualified ore returns to the grinding process. The qualified ore after grinding is pulped underground, and the ore slurry produced is stored in the underground slurry storage tank, and then the ore slurry is pumped to the surface through the slurry pipeline and slurry pump. The water used for pulping is the underground drainage of the mine, that is, the surface water that needs to be pumped and discharged from the underground. In the pumping process, water is used as a carrier to pump the prepared slurry to the surface. The filtered drainage of the surface pulp is used for ore pulping. After the pulp is ...

Embodiment 2

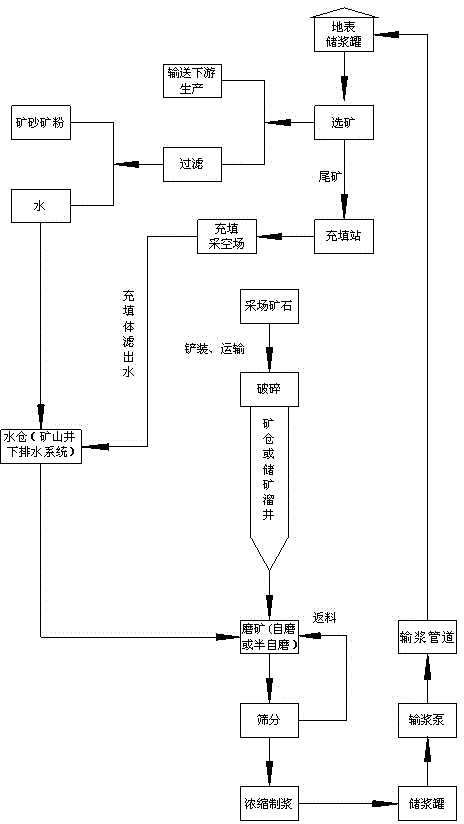

[0028] Such as figure 2 Shown in the figure is an ore lifting method in an underground mine. The ore mined by crushing underground is shoveled and transported to a mine bin or a storage chute to be processed in the next process. The ore after pulp crushing is ground underground, and the grinding is autogenous or semi-autogenous. After grinding, the ore is screened, and the ore with a suitable particle size enters the pulping process, and the unqualified ore returns to the grinding process. The qualified ore after grinding is pulped underground, and the ore slurry produced is stored in the underground slurry storage tank, and then the ore slurry is pumped to the surface through the slurry pipeline and slurry pump. The water used for pulping is the underground drainage of the mine, that is, the surface water that needs to be pumped and discharged from the underground. In the pumping process, water is used as a carrier to pump the prepared slurry to the surface. The filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com