A single ridge and double row automatic soil covering machine

A single ridge, double row, film covering machine technology, applied in the field of tobacco, can solve the problems of inability to realize fully automatic soil covering operation, inability to apply soil effectively and evenly, and affect the growth of crops. Simple, mechanical and highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

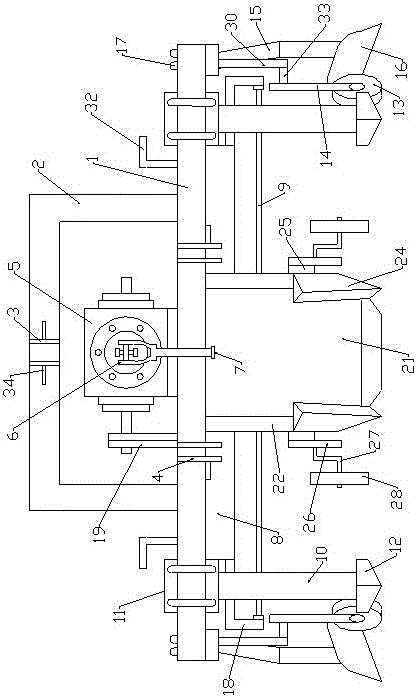

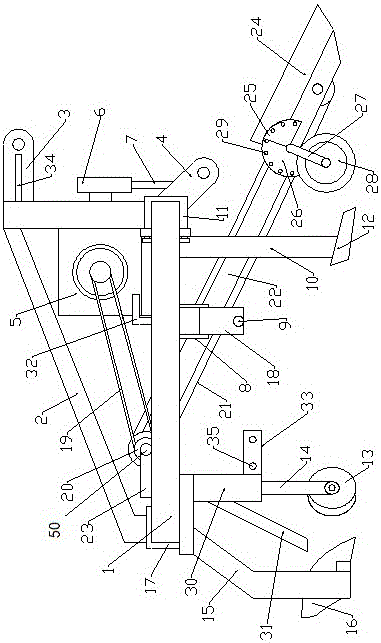

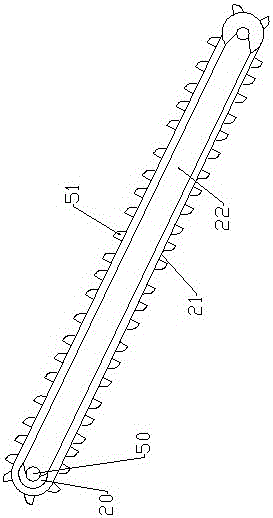

[0018] Such as figure 1 , 2 , Shown in 3, a kind of single ridge double-row automatic covering machine, comprises support 1, the support 2 that is installed on the support 1, the opener 12 that is installed on support 1 front both sides, is arranged on The film-coated support roller 9 below the support 1 is movably installed on the gatherer 16 at the rear of the support 1. The middle part of the support 1 below the support 2 is fixedly installed with a reducer 5, and the input end of the reducer 5 is installed There is a power input shaft 7, and the output end of the reducer 5 is connected with the rotating shaft 20 through the belt pulley 19, and a rotating bracket 23 is fixedly installed on one side of the rotating shaft 20, and the rotating bracket 23 is connected with the movable bracket 22, and the movable bracket 22 is a slope shape, the outer side of the rotating shaft 20 is equipped with a crawler belt 21, the bottom of the crawler belt 21 is provided with a gathering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com