Continuous mixing device and method of fracturing fluid

A fracturing fluid and mixing technology, which is applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of high labor intensity, waste, and long liquid preparation time, so as to improve work efficiency, reduce investment, The effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

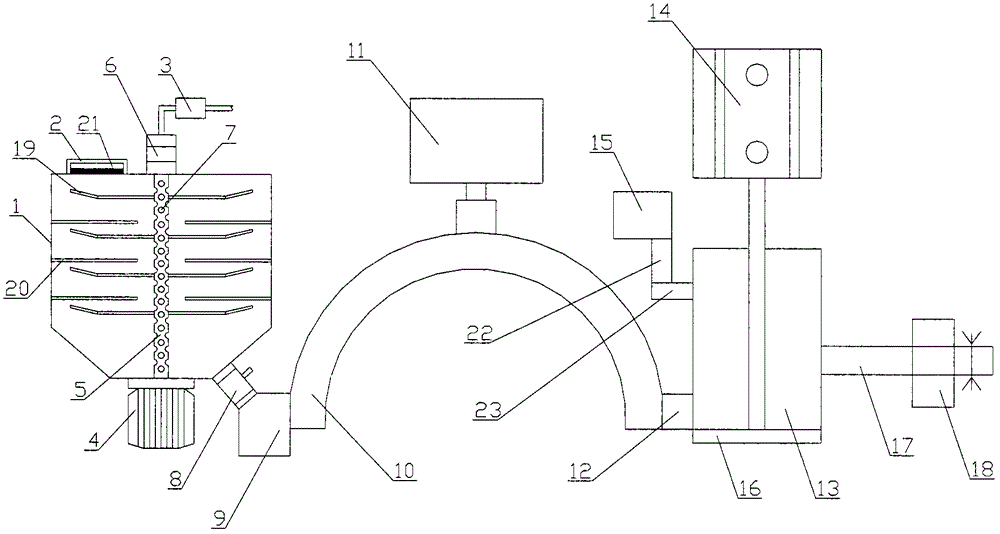

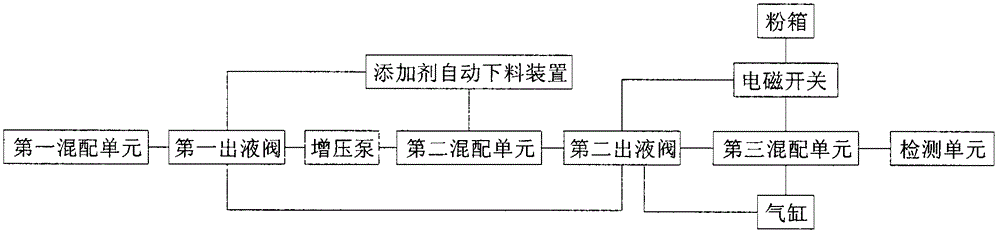

[0021] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0022] Such as figure 1 with figure 2 As shown, a fracturing fluid continuous mixing equipment includes a first mixing unit, a second mixing unit, a third mixing unit, and a detection unit 18 that are sequentially connected, and the first mixing unit includes a mixing tank 1 , The feed port located on the upper side of the mixing kettle 1, the water inlet valve 3 located in the upper middle of the mixing kettle 1, and the motor 4 located at the bottom of the mixing kettle 1. The motor 4 is installed vertically and the rotating shaft of the motor 4 Located above the main body of the motor 4, the rotating shaft of the motor 4 is connected with a water outlet pipe 5 for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap