Reaction container and method for preparing composite material filled with polyethylenedioxythiophene

A technology of ethylenedioxythiophene and reaction vessel, which is applied in the direction of pressure vessel used in chemical process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

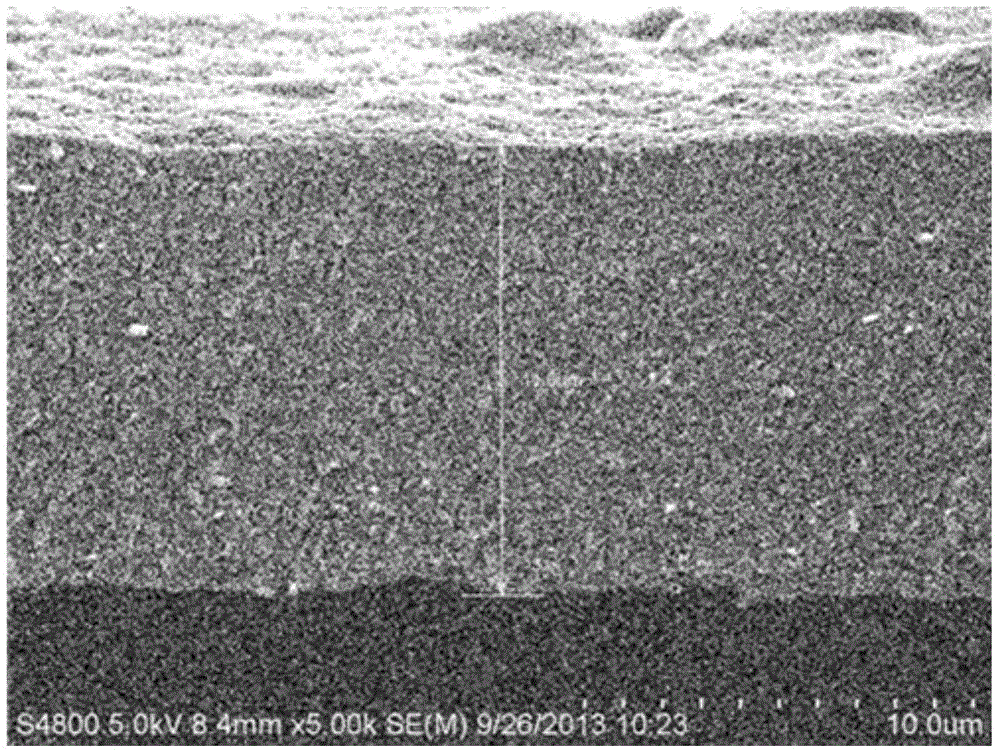

Image

Examples

Embodiment 1

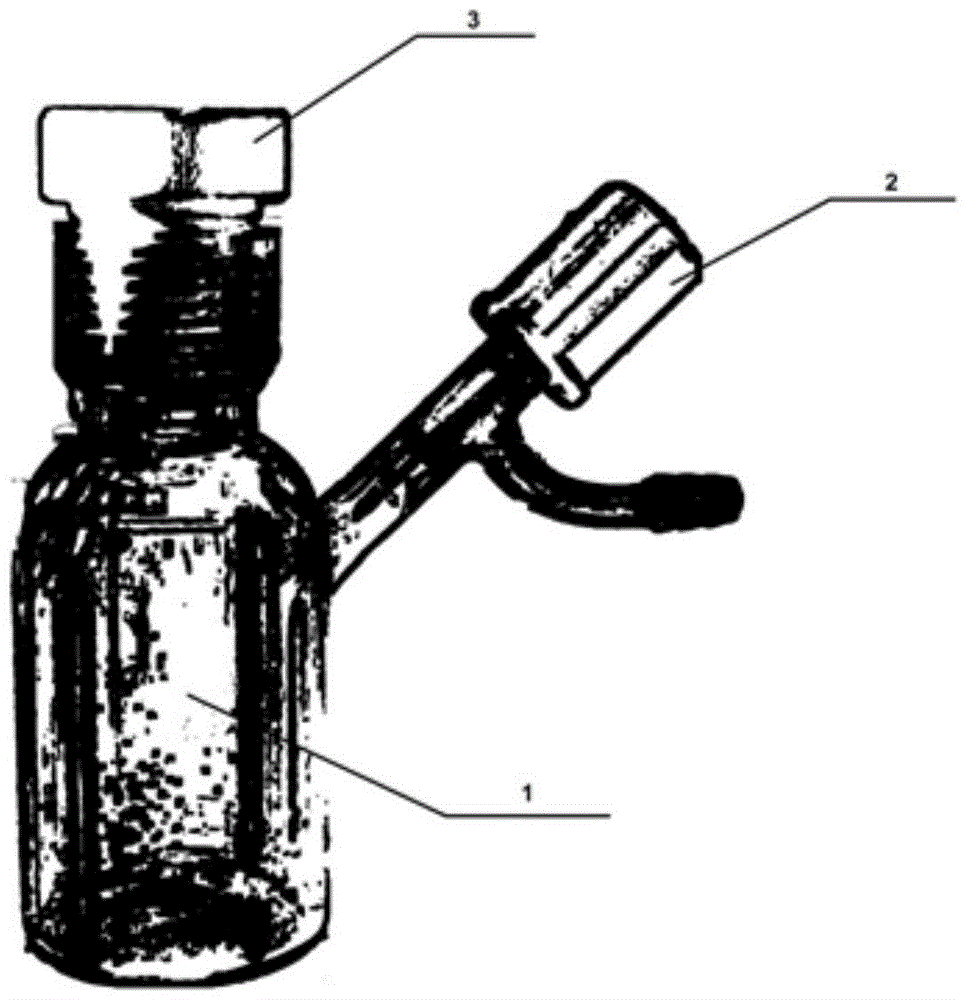

[0031] In the present invention, the reaction vessel for preparing composite materials by modifying poly-3,4-ethylenedioxythiophene on the surface of inorganic oxide nanoparticles is as follows: figure 2 As shown, it includes a bottle body 1, a high vacuum regulating valve 2 and a threaded sealing plug 3 with a silicone rubber sealing ring. A threaded sealing plug 3 with a silicon rubber sealing ring is capped at the bottleneck of the bottle body 1, and a high vacuum regulating valve 2 is arranged at the branch pipe mouth of the bottle body 1. When in use, the bottle mouth is opened by rotating the threaded sealing plug 3 with a silicone rubber sealing ring, the sample is added, the high-vacuum regulating valve 2 is opened, and the whole system is evacuated through the branch pipe to achieve a vacuum state.

[0032] The preparation method of filling poly-3,4-ethylenedioxythiophene on the surface of titanium dioxide nanoparticles and particle gaps comprises the following steps...

Embodiment 2

[0037] The preparation method of filling poly-3,4-ethylenedioxythiophene on the surface of manganese dioxide nanoparticles and particle gaps comprises the following steps:

[0038] (1) Mix manganese sulfate solution with a concentration of 75mM and potassium permanganate solution with a concentration of 50mM under vigorous stirring, filter under pressure, and dry the precipitate at 100°C. The obtained manganese dioxide solid and ethylene glycol were mixed according to a mass ratio of 1:2, and ball milled in a ball mill at a rotational speed of 1800rmp for 8h to obtain a manganese dioxide slurry.

[0039] (2) Coat the manganese dioxide slurry on the conductive glass, spin-coat at 4000rpm for 45s, and dry at 100°C for 30min to ensure that the solvent is completely volatilized to obtain a layer of manganese dioxide nanoparticle film.

[0040] (3) Add 3,4-ethylenedioxythiophene to the chloroform solution with a volume fraction of 30% formic acid, add 1,3-dibromo-5,5-dimethyl-2,4 ...

Embodiment 3

[0043] The preparation method of filling poly-3,4-ethylenedioxythiophene on the surface of alumina nanoparticles and particle gaps comprises the following steps:

[0044] (1) Coat the aluminum oxide nanoparticle dispersion on the conductive glass, spin-coat at 2000rpm for 60s, and dry at 150°C for 30min to ensure that the solvent is completely volatilized to obtain a layer of aluminum oxide nanoparticle film.

[0045] (2) 3,4-ethylenedioxythiophene is added to the chloroform solution of acetic acid with a volume fraction of 40%, and 1,3-dibromo-1,3,5-triazine-2 is added under ice-cooling, 4,6-triketone undergoes bromination reaction, and the reaction time is 8-24h. After the reaction was completed, deionized water was added to the organic solution to quench the reaction, and the organic phase was extracted and separated. The neutralized organic phase was washed with 10% potassium carbonate alkaline aqueous solution, and the organic phase was separated. The solvent in the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com