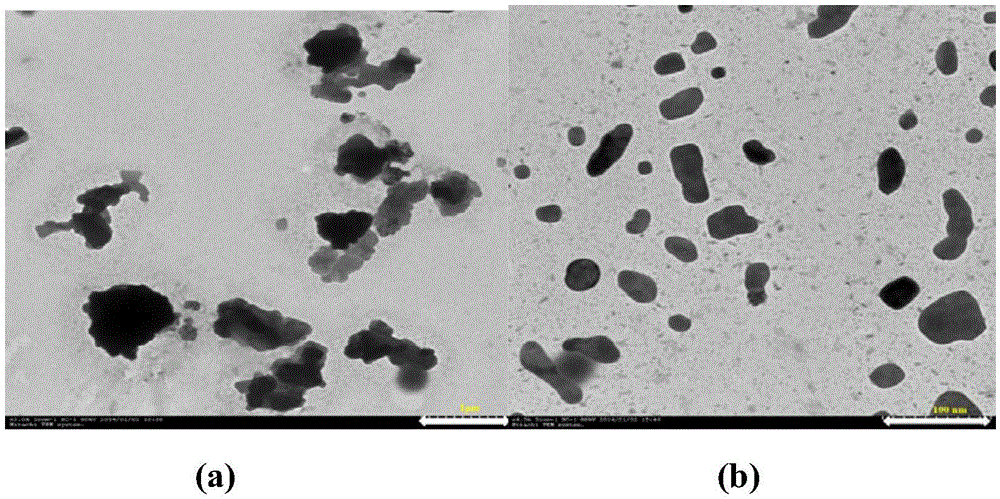

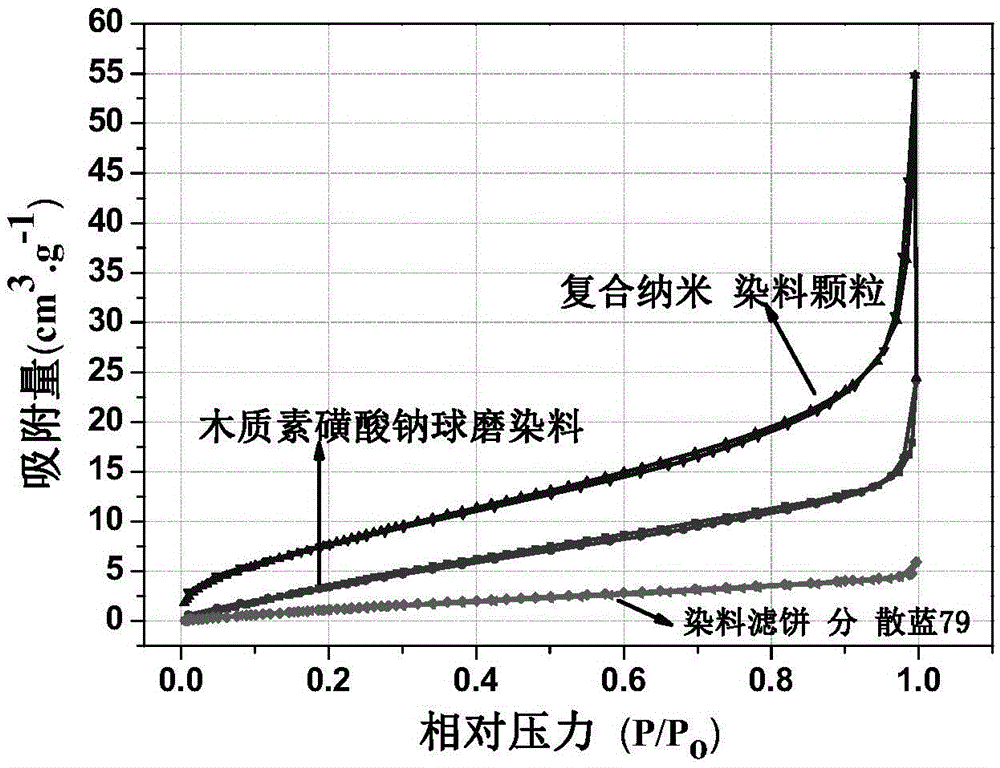

A kind of lignin-based nano disperse dye and preparation method thereof

A nano-dispersion and disperse dye technology, applied in the direction of organic dyes, etc., can solve problems such as detachment, system dispersion stability decline, uneven particle size distribution, etc., to achieve the effect of stabilizing the dispersion system and increasing steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1: Preparation of lignin-based nano-disperse dyes of the present invention

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Preparation of active intermediates

[0089] 5g ethanol and butanol (volume ratio 1:1) mixture are added in water, be mixed with concentration and be the fatty alcohol aqueous solution of 10% by weight, then use the sulfuric acid aqueous solution of 10% by weight to dissolve described fatty alcohol aqueous solution Adjust the pH to 4, then add 5g of epichlorohydrin and 0.2g of boron trifluoride diethyl ether catalyst, and then react at a temperature of 30°C for 1h, thus obtaining the active intermediate of polyhydric fatty alcohol compound;

[0090] B. Preparation of dispersant aqueous solution

[0091] 100g is sold by the sodium lignosulfonate of trade name M-9 by Tumen City Shixian Advance Chemical Co., Ltd. and the magnesium lignosulfonate (weight ratio 1: 3) The mixture of the mixture is added into ...

Embodiment 2

[0101] Embodiment 2: Preparation of lignin-based nano-disperse dyes of the present invention

[0102] The implementation steps of this embodiment are as follows:

[0103] A. Preparation of active intermediates

[0104] 20g propanol is added to water, is mixed with concentration and is the fatty alcohol aqueous solution of 40% by weight, then is that the pH of described fatty alcohol aqueous solution is adjusted to 7 by the hydrochloric acid aqueous solution of 8% by weight with concentration, then adds 20g1, 2-epoxychlorobutane and 1g of tin tetrachloride catalyst were reacted at a temperature of 80° C. for 3 hours to obtain the active intermediate of polyhydric fatty alcohol compound;

[0105] B. Preparation of dispersant aqueous solution

[0106] 100g of calcium lignosulfonate sold under the trade name wood calcium by Yanbian Chenming Paper Co., Ltd. is added into water to be mixed with a concentration of 35% by weight in water, followed by 30% by weight of potassium hydro...

Embodiment 3

[0110] Embodiment 3: Preparation of lignin-based nano-disperse dyes of the present invention

[0111] The implementation steps of this embodiment are as follows:

[0112] A. Preparation of active intermediates

[0113] 15g hexanol is added to water, is mixed with concentration and is the fatty alcohol aqueous solution of 30% by weight, then is that the pH of described fatty alcohol aqueous solution is adjusted to 6 with the sulfuric acid aqueous solution of 15% by weight with concentration, then adds 15g ring Oxychloropropane and 0.8g boron trifluoride diethyl ether catalyst were reacted for 2 hours at a temperature of 50° C., thus obtaining the active intermediate of polyhydric fatty alcohol compound;

[0114] B. Preparation of dispersant aqueous solution

[0115] 100g of sulfonated lignin sold under the trade name lignin dispersant S by Shaoxing Guotai Auxiliary Factory is added to water, and it is mixed with a concentration of 40% aqueous solution by weight, followed by 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com