Environment-friendly dust removing mechanism

An environment-friendly and body-friendly technology, applied in textiles, papermaking, knitting, etc., can solve problems such as non-environmental protection, physical hazards, and excessive dust accumulation, and achieve the effect of fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

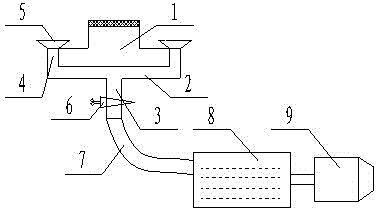

[0012] See figure 1 , The embodiment of the present invention includes:

[0013] An environmentally-friendly dust removal mechanism, comprising: a body 2, a brush 1 and a water tank 8. The body 2 is hollow, the upper surface of the body 2 is concave in the middle, and both ends are raised 4, and the brush 1 is fixedly installed In the recess of the body 2, the protrusions at both ends of the body 2 are connected with nozzles 5, and the middle of the lower end surface of the body 2 is connected with a branch pipe 3, and the branch pipe 3 is provided with a switch 6, the The lower end of the branch pipe 3 is connected to the water ta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap