Underground Coal Gasifier and Method for Determining Combustion State of Furnace

A technology of underground gasification and combustion state, applied in coal gasification, underground mining, earthwork drilling and other directions, can solve the problem of inability to accurately judge the combustion state, and achieve the effect of high accuracy and timely judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

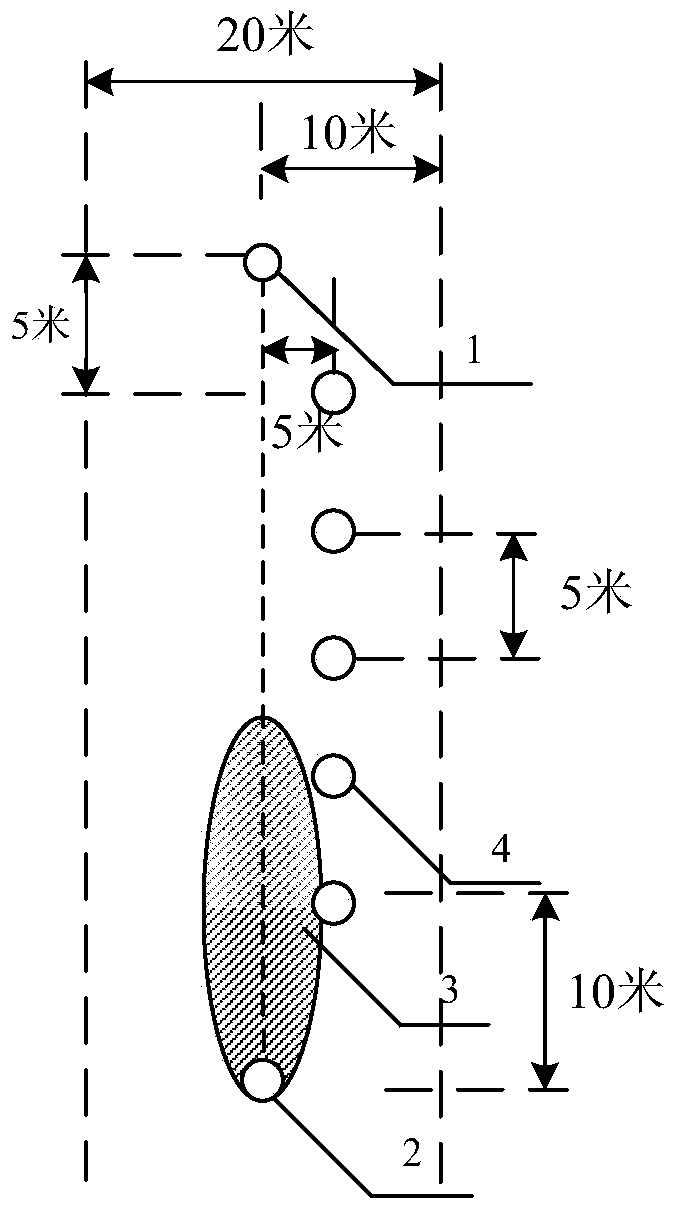

[0035] figure 1 and figure 2 It is a schematic diagram of the surface structure of the underground coal gasifier of the first embodiment of the present invention. see figure 1 , the underground coal gasification process is to drill holes from the ground to the coal seam, one of which is the air inlet hole 1, and the other hole is the air outlet hole 2, and coal seam fracturing and other methods are used to form gasification channels in the two holes (not shown). After ignition, the gasification agent (air, water vapor, oxygen-enriched air, etc.) Convey from air outlet 2 to the ground. During the gasification process, the gasification channel expands continuously with the combustion of the coal seam, forming a burn-out zone 3 .

[0036] In addition to the above-mentioned air inlet 1, air outlet 2, and air flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com