Device and method for recycling steam waste heat in alum production

A steam waste heat and steam technology, applied in the chemical industry, can solve the problems of non-compliance with energy saving and emission reduction, energy waste, increase of production cost, etc., and achieve the effect of saving coal consumption, reducing environmental pollution, and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

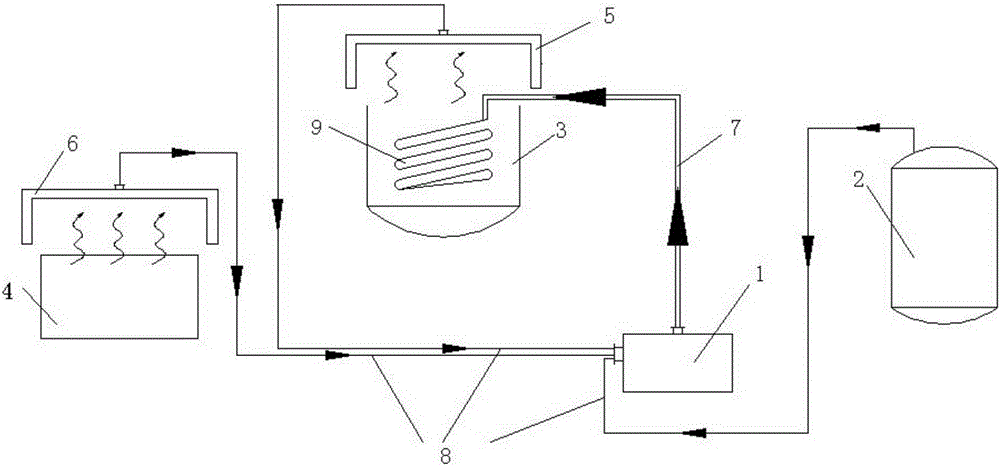

[0019] A device for recycling steam waste heat in alum production, including a boiler (1), a reaction kettle (2), an evaporation concentration tank (3), a cooling crystallization tank (4), a first steam collector (5), and a second steam collector (6), heat transfer pipe (7), waste heat pipe (8) and titanium heating pipe (9), the steam outlet of the reaction kettle (2) communicates with the air inlet of the boiler (1) through the waste heat pipe (8) , the first steam collector (5) is arranged above the evaporation concentration tank (3), and the steam outlet of the first steam collector (5) communicates with the boiler (1) through a waste heat pipe (8) The air inlet of the second steam collector (6) is arranged above the cooling crystallization tank (4), and the steam outlet of the second steam collector (6) communicates with the The air inlet of the boiler (1), the titanium heating tube (9) is arranged in the evaporation concentration tank (3), the steam outlet of the boiler (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com