Novel transformer core positioning structure and method

A positioning structure and positioning method technology, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor magnetic core, transformer/inductor parts, etc. To solve problems such as large thickness, achieve the effect of improving the no-load current value and noise level value, alleviating the increase of magnetic density, and reducing the diffraction size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

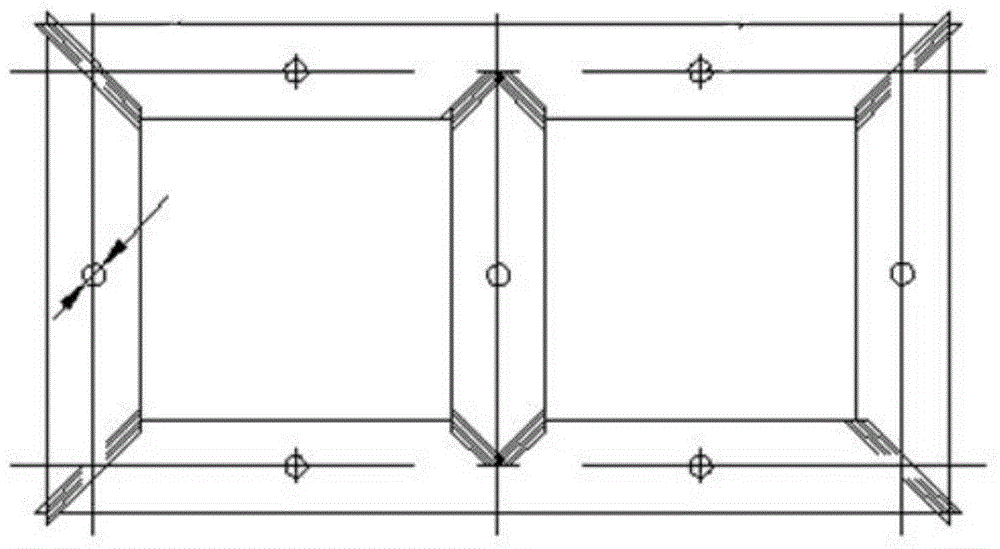

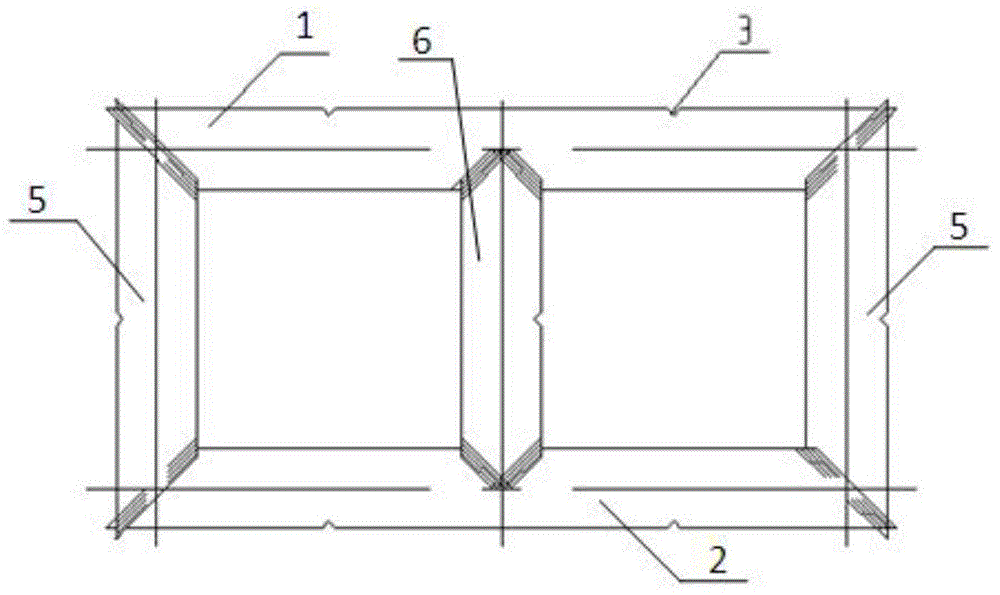

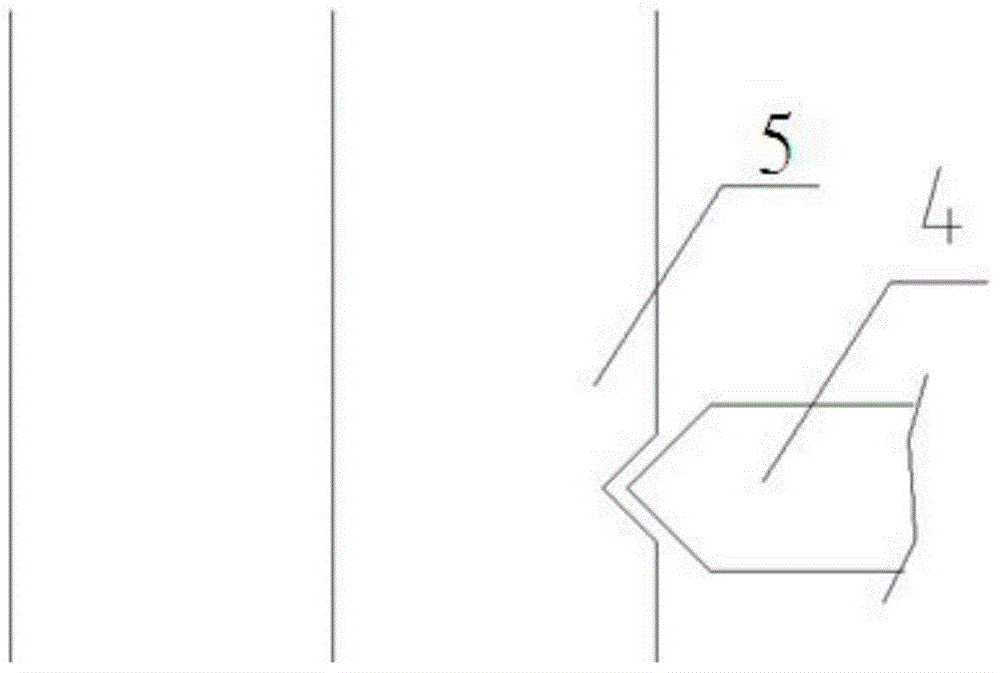

[0023] In order for the examiner to better understand the technical features, technical content and technical effects achieved by the present invention, the drawings of the present invention will now be described in more detail in conjunction with the embodiments. However, the drawings shown are only to better illustrate the technical solution of the present invention, and are not the true proportions and optimal configuration of the present invention. Therefore, the examiner is requested not to limit the scope and configuration of the present invention based on the comparison and configuration of the drawings. Claim protection scope.

[0024] The patent of the present invention will be further described below in conjunction with the drawings and embodiments.

[0025] Such as Figure 1-3 As shown, the present invention provides a novel positioning structure for a transformer core, which includes an iron core and a tooling profile 4, the upper end of the iron core is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap