The Method of Improving the Comprehensive Performance of the Miscellaneous Ladder

A comprehensive performance, debris ladder technology, used in elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of large overall floor space, inconvenient opening and closing of floor doors, inconvenient opening and closing operations, etc. The effect of reducing the overall floor space, easy adjustment of the derrick precision, and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

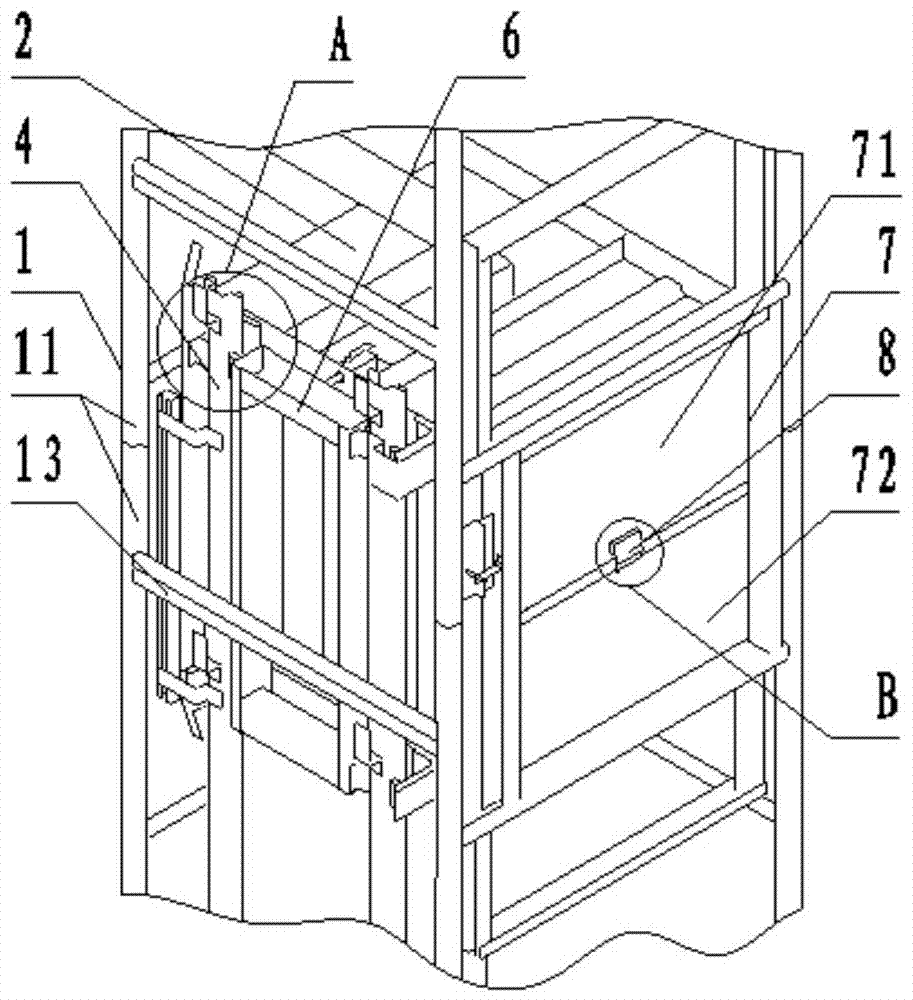

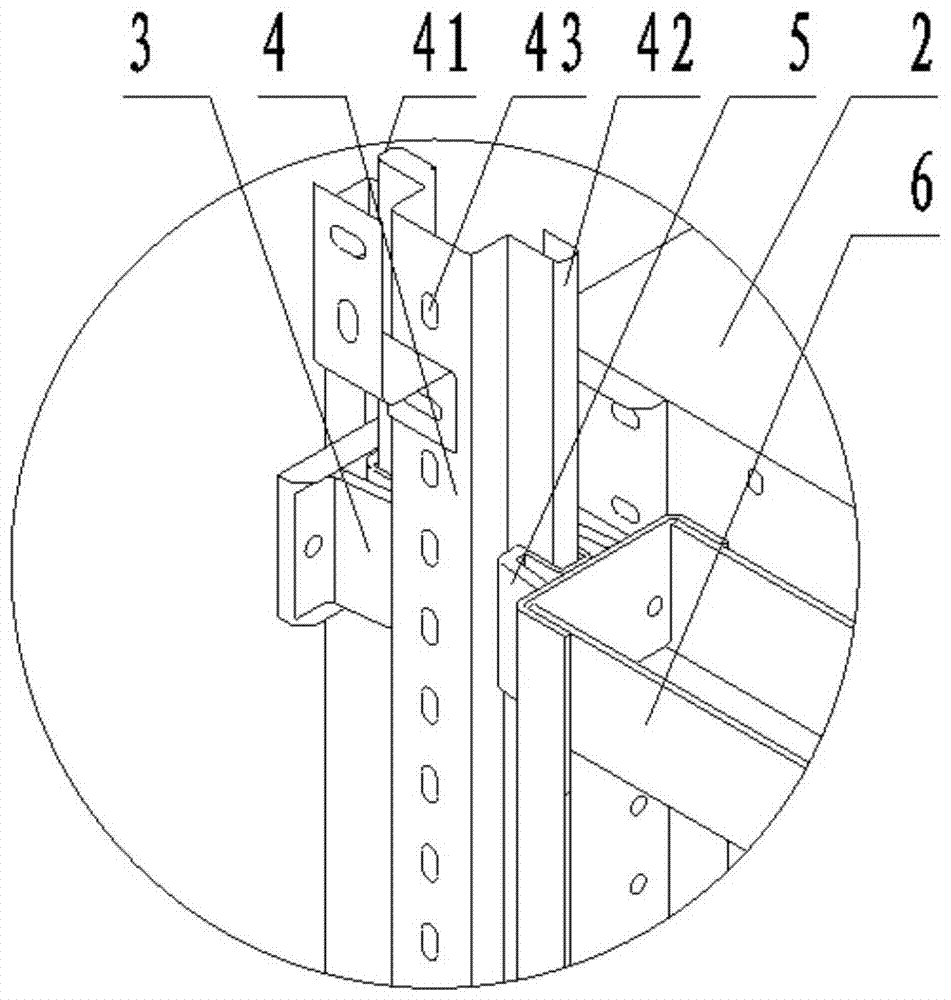

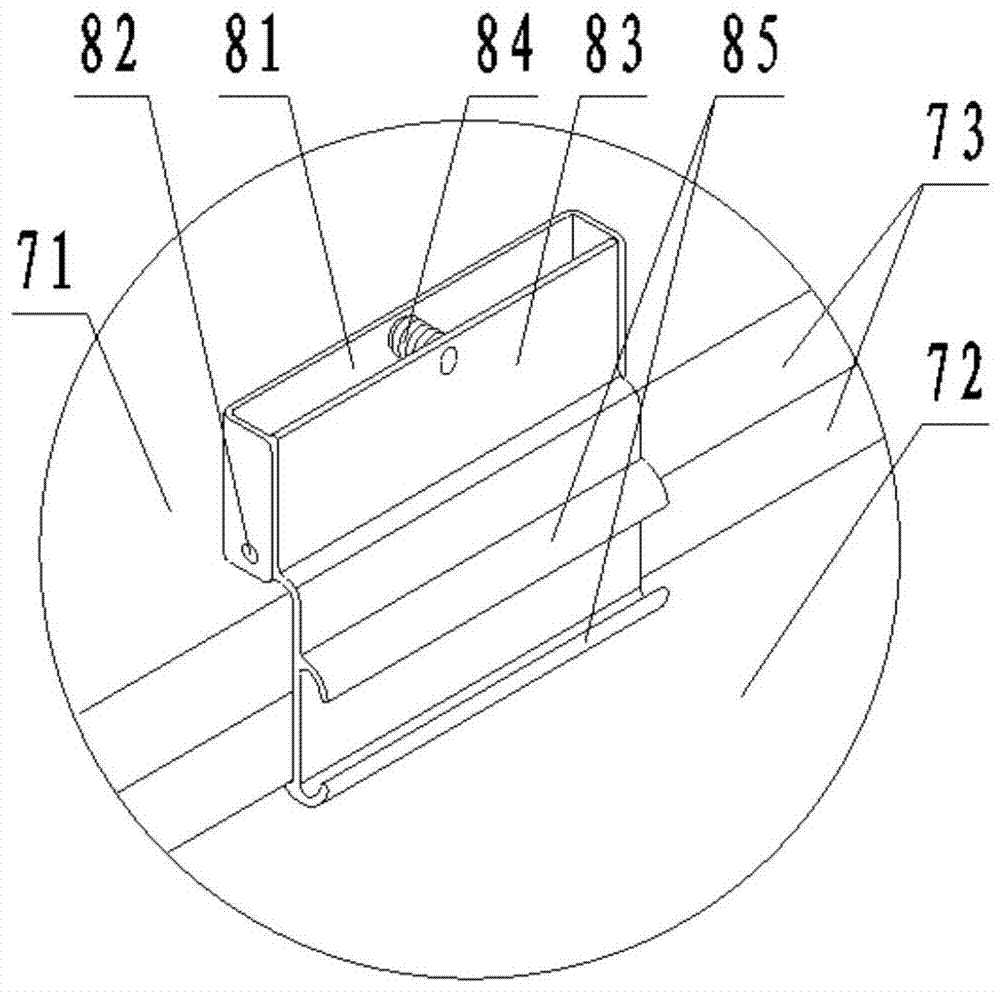

[0021] Example. A method for improving the comprehensive performance of the debris elevator, the method connects the car guide shoe 3 on one side of the guide rail 4, and connects the counterweight guide shoe 5 on the other side of the guide rail 4, so that the car 2 and the counterweight 6 share the guide rail 4, Make the structure of the car 4 and the counterweight 6 compact and reduce the overall floor area; uniformly set a number of waist holes 12 on the column 11 of the derrick 1, connect the column 11 and the beam 13 through the waist holes 12, and then splice through the column connector 14 Two columns 11 facilitate the installation and adjustment of the derrick 1; the switch of the upper door 71 and the lower door 72 is convenient through the door handle device 8 .

[0022] The debris ladde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com