Cold continuous rolling method of brass wires

A technology of cold continuous rolling and brass, applied in the field of cold continuous rolling process of binary brass wire rod, can solve the problems of reduced production efficiency, non-dense structure of brass casting billet, long production process flow, etc., so as to improve production efficiency , the effect of shortening the process flow and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

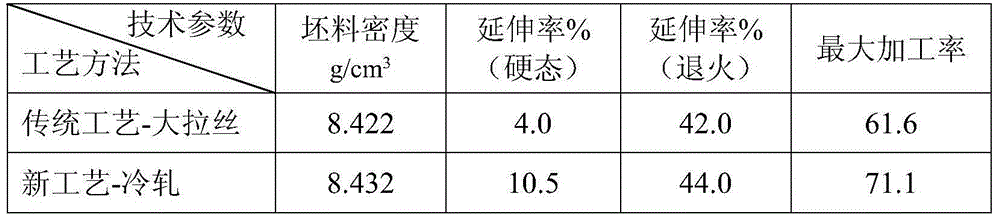

[0023] Example 1: Under the same processing rate, the brass up-drawing continuous casting Φ12 bar billet was processed to a Φ7.7 wire billet by the stretching method and the cold rolling method respectively.

[0024] (1) Ingredients: according to the bright line 40wt%, brass corner material 30wt%, zinc ingot and inevitable impurities 30wt%, the total amount of impurities is not more than 0.4wt% except Ni;

[0025] (2) Melting: Put the bright wire, brass corner stock, and zinc ingot into the induction electric furnace in batches for smelting. The smelting temperature is 1030~1080℃, and the temperature is kept after all the metals are melted;

[0026] (3) Upward continuous casting: The copper water is continuously drawn upward from the holding furnace by the mold, the rod billet size is Φ12mm, and the traction speed is 2.0m / min;

[0027] (4) Cold rolling: The brass top rod billet is continuously rolled to Φ7.7mm through a multi-stand rolling mill, the number of stands is 10, the rolling ...

Example Embodiment

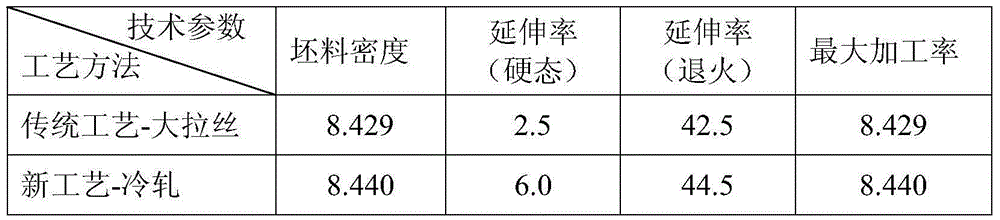

[0041] Example 2: Under the condition of the same processing rate, the brass up-drawing continuous casting Φ12 up-drawing continuous casting rod billet is processed to the Φ7.2 wire billet by the stretching method and the cold rolling method respectively.

[0042] (1) Ingredients: according to the bright line 40wt%, brass corner material 30wt%, zinc ingot and inevitable impurities 30wt%, the total amount of impurities is not more than 0.4wt% except Ni;

[0043] (2) Melting: Put the bright wire, brass corner stock, and zinc ingot into the induction electric furnace in batches for smelting. The smelting temperature is 1030~1080℃, and the temperature is kept after all the metals are melted;

[0044] (3) Upward continuous casting: The copper water is continuously drawn upward from the holding furnace by the mold, the rod billet size is Φ12mm, and the traction speed is 2.0m / min;

[0045] (4) Cold rolling: The brass top rod billet is continuously rolled to Φ7.2mm through a multi-stand rollin...

Example Embodiment

[0059] Example 3: Under the condition of the same processing rate, the Φ8 up-drawing continuous casting rod blank is processed to the Φ5 wire blank by the stretching method and the cold rolling method respectively.

[0060] (1) Ingredients: According to the bright line 20-40wt%, brass corner material 30-50wt%, zinc as the balance and inevitable impurities, the total amount of impurities is not more than 0.4wt% except Ni;

[0061] (2) Melting: Put the bright wire, brass corner stock, and zinc ingot into the induction electric furnace in batches for smelting. The smelting temperature is 1030~1080℃, and the temperature is kept after all the metals are melted;

[0062] (3) Upward continuous casting: Copper water is continuously drawn upward from the holding furnace by the crystallizer, the billet size is Φ8mm, and the pulling speed is 2.0m / min;

[0063] (4) Cold rolling: The brass top rod billet is continuously rolled to Φ5mm through a multi-stand rolling mill, the number of stands is 8, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap