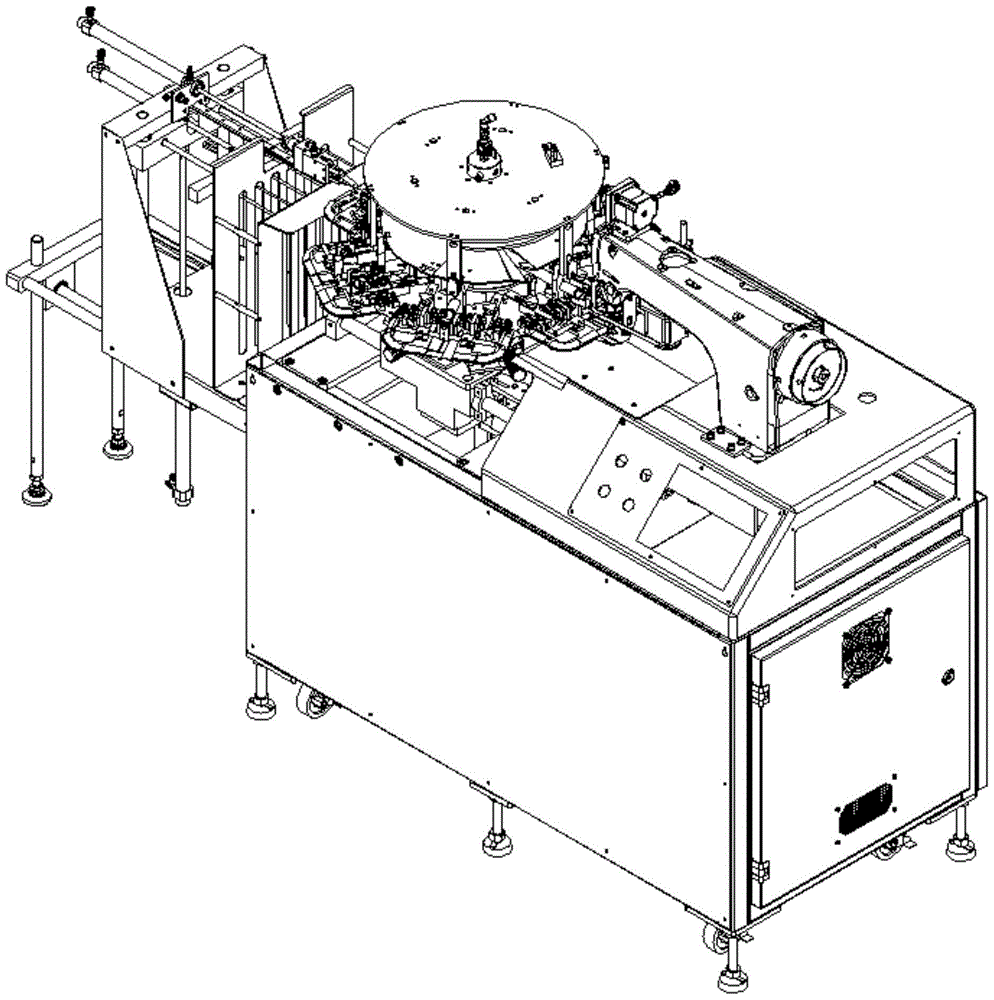

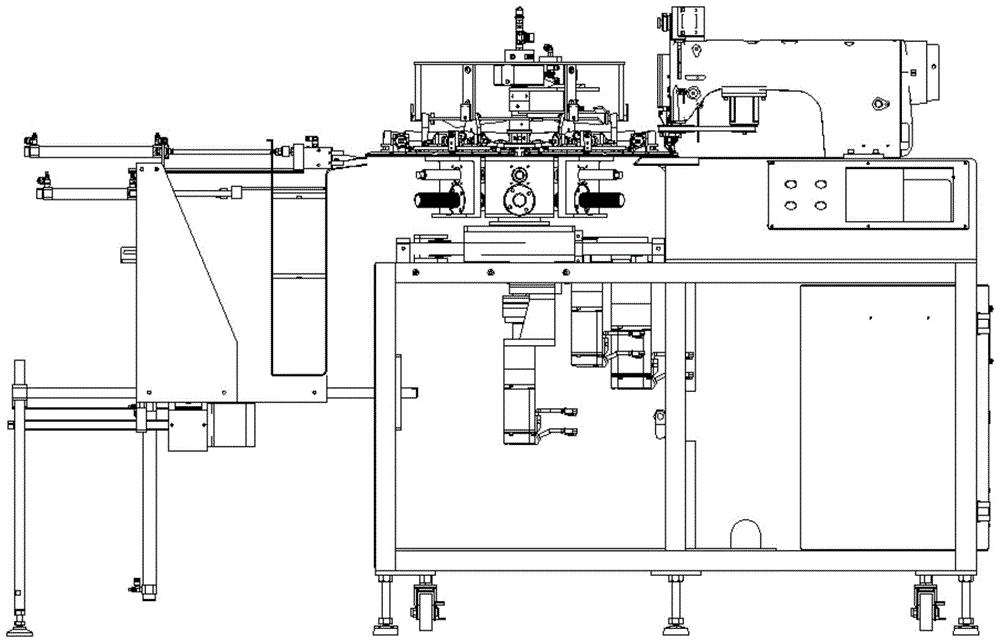

A combined pressing plate assembly structure of a material-carrying turntable mold for an automatic sewing machine

An assembly structure, sewing machine technology, applied in sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of long delivery cycle of new molds, complicated mold installation and replacement, and many installation and replacement steps, so as to shorten the research and development cycle, install The effect of fewer replacement parts and fewer installation and replacement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

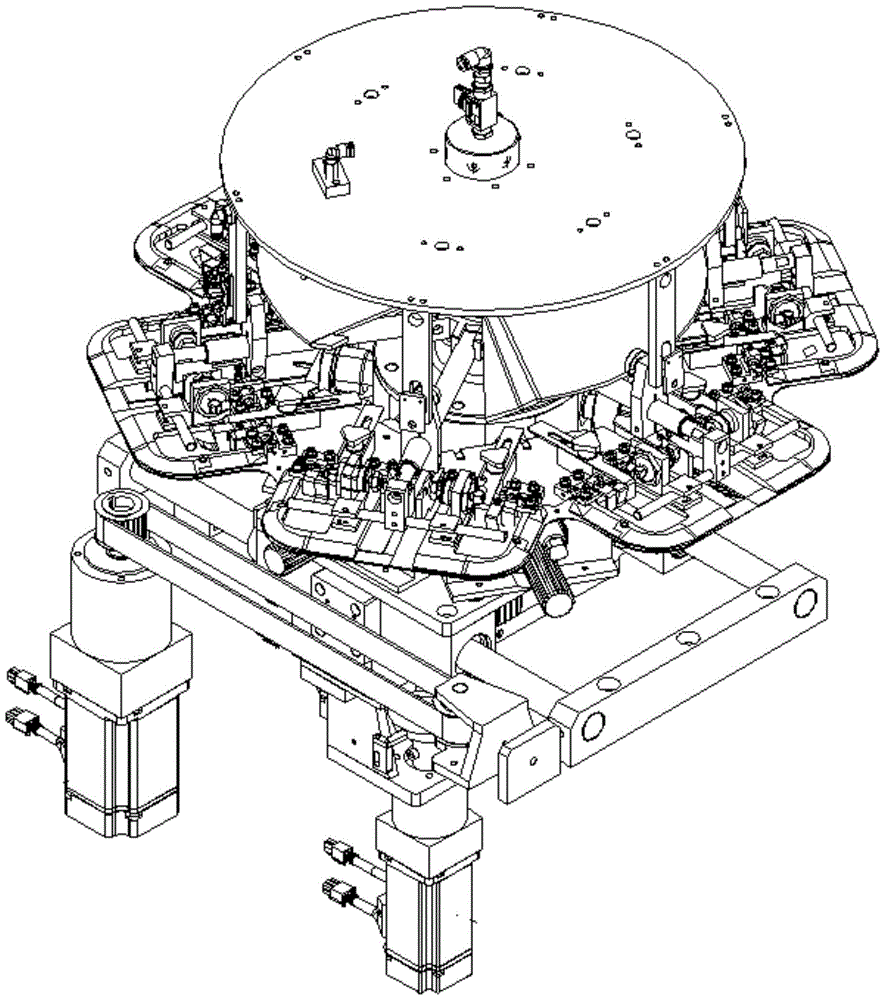

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] see Figure 5-6 , a combined press plate assembly structure of an automatic sewing machine loading turntable mold, a bottom template 1 is fixedly arranged on the upper part of the automatic sewing machine loading turntable mold, an upper template is also fixedly arranged above the bottom template, and the arc angle of the upper template is A detachable corner module 2 is provided at the position, and the corner module 2 corresponds to the corner part of the bottom template 1; according to the sewing track requirements, when the mold is switched, a pair of corresponding corner modules 2 and the bottom template are replaced at the same time. Template 1.

[0032] Due to the large volume of the loading turntable mold, the long production cycle and high price, the present invention can also achieve the effect of switching molds by disassembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com