Casting spiral scraper knife blade

A technology of spiral scraper and knife wing, applied in the field of machinery, can solve the problems of poor mud removal, poor well quality, poor trimming effect, etc., and achieve the effect of facilitating cutting removal, improving well quality and drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

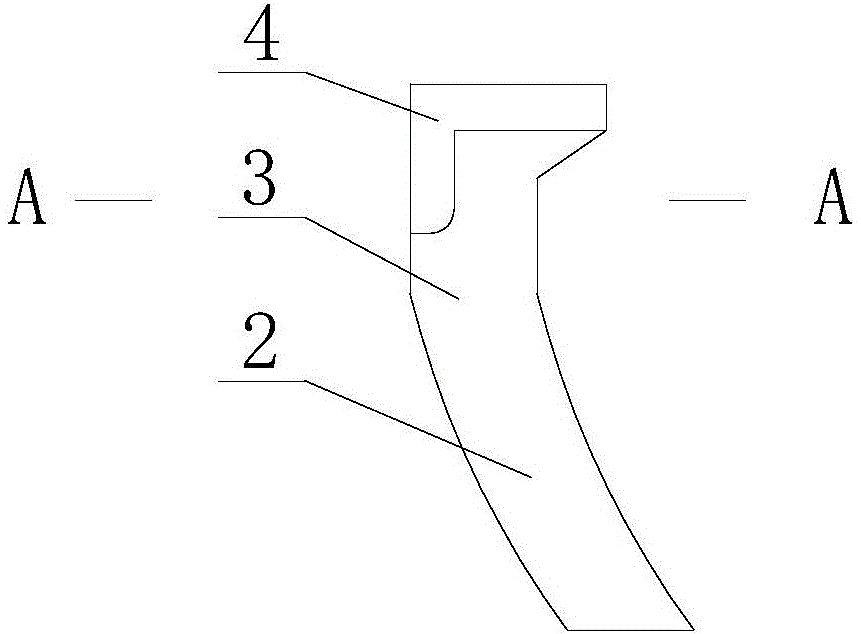

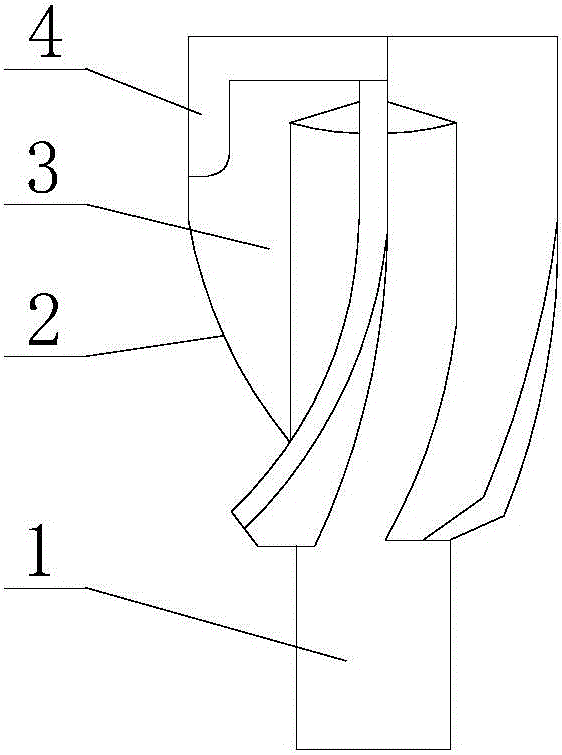

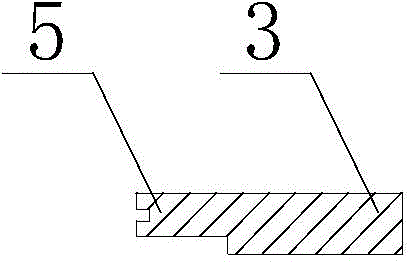

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] Depend on Figure 1 to Figure 3 As shown, a cast spiral scraper blade includes a cutter body 3, several cutter bodies 3 are uniformly fixed on the drill body 1, the cutter body 3 and the drill body 1 are welded, and the upper end of the cutter body 3 is a cutting section 4 , the front end and the side of the cutting section 4 are cutting edges 5, and the cutting edges 5 have the same structure as the cutting edge of the existing scraper blade. The lower end of the cutter body 3 is a gauge section 2, the cutting section 4 is smoothly connected with the gauge section 2, and the gauge section 2 is a spiral shape along the outer circumference of the drill body 1, that is, the gauge section on each cutter body 3 2 spirally rotates in the same direction along the outer circumference of the drill body 1, and the length of the gauge section 2 is greater than the length of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap