A kind of processing method of ethylene waste lye

A technology for ethylene waste lye and treatment methods, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., and can solve high operating costs, inappropriate waste lye, and large investment and other issues, to achieve the effect of guaranteeing recovery rate, reducing usage, and effectively recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

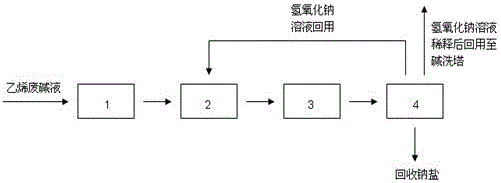

Image

Examples

Embodiment 1

[0027] One piece of waste lye produced in the production process of ethylene, wherein: COD is 58000mg / L, sodium sulfide concentration is 2.9wt% (S 2- : 12200mg / l), the concentration of sodium carbonate is 2.0wt% (20500mg / L), the concentration of sodium hydroxide is 1.6wt%, and the concentration of oil is 240mg / L. Adopt the inventive method to process under the following conditions:

[0028] Air flotation degreasing: Air is introduced into the ethylene waste lye to generate air bubbles in the waste lye, and the trace light oil entrained in the waste lye sticks to the air bubbles and is removed by floating on the water surface with the gas. After air flotation and deoiling treatment, the oil content in the waste caustic liquor was reduced to 16mg / L.

[0029]High-temperature wet oxidation treatment: add 50wt% sodium hydroxide solution to the waste lye, preferably the sodium hydroxide solution obtained after the treatment of the present invention. Add 120L of 50wt% sodium hydrox...

Embodiment 2

[0033] One piece of waste lye produced in the production process of ethylene, wherein: COD is 33000mg / L, and sodium sulfide concentration is 2.1wt% (S 2- : 8831mg / l), the concentration of sodium carbonate is 1.1wt% (11275mg / L), the concentration of sodium hydroxide is 1.2wt%, and the concentration of oil is 175mg / L. Adopt the inventive method to process under the following conditions:

[0034] Air flotation degreasing: Air is introduced into the waste lye to generate air bubbles in the waste lye, and a small amount of light oil entrained in the waste lye sticks to the air bubbles, and is removed by floating on the water surface with the gas. After the air flotation and oil removal treatment, the oil content in the waste caustic liquor was reduced to 13mg / L.

[0035] High-temperature wet oxidation treatment: add 40wt% sodium hydroxide solution to the waste lye, preferably the sodium hydroxide solution obtained after the treatment of the present invention. Add 150L of 40wt% so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com