High-speed rail signal tool managing system

A tool management and signal technology, applied in the field of tool management, can solve the problems of tool mixing and loss, and achieve the effect of avoiding mixing and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

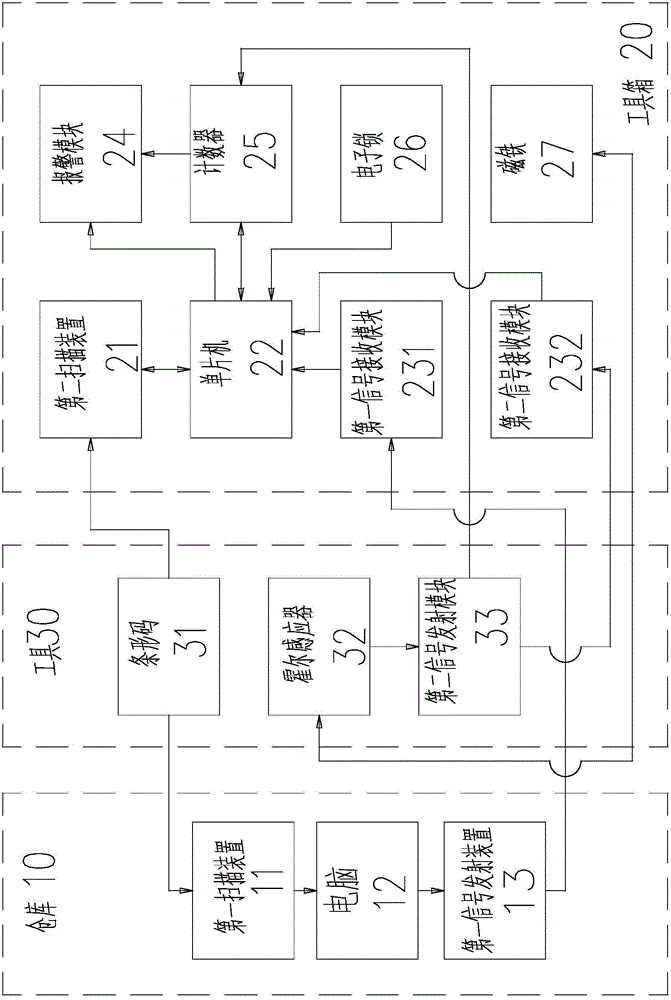

[0018] Examples, see figure 1 As shown: the high-speed rail signal tool management system, including a warehouse 10 for storing at least one tool 30 and a tool box 20 for carrying at least one tool 30 . The management system is used to prevent the tools 30 carried by the workers to the work site through the tool box 20 after leaving the warehouse 10 from being lost on the work site after use. Specifically:

[0019] The warehouse 10 is provided with a first scanning device 11 . The first scanning device 11 is signal-connected to a computer 12 , and the computer 12 is connected to a first signal transmitting module 13 .

[0020] The tool box 20 is equipped with an electronic lock 26 . Simultaneously, be provided with the counter 25 of the second scanning device 21, single-chip microcomputer 22, first signal receiving module 231, the second signal receiving module 232, alarm module 24 and initial count value zero in this toolbox 20; The mouth is provided with a magnet 27 . W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com