Method for extracting aluminium oxide from coal ash

A technology of fly ash and alumina, applied in the direction of alumina/hydroxide, energy input, etc., can solve the problems that the extraction of alumina from fly ash cannot truly realize industrial production, the process is difficult to operate, and the energy consumption is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

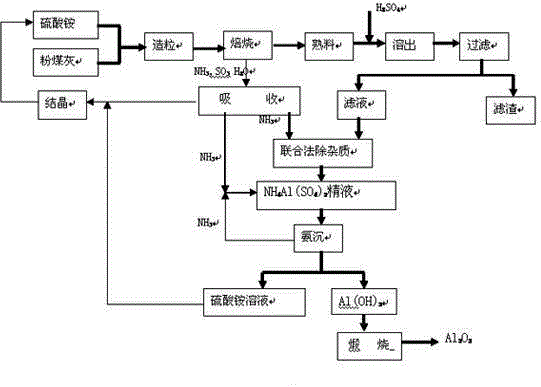

[0072] Embodiment 1: see figure 1

[0073] (1) Fly ash and ammonium sulfate (NH 4 ) 2 SO 4 Mixing granulation

[0074] Add 33.26 tons (NH 4 ) 2 SO 4 , so that fly ash and (NH 4 ) 2 SO 4 The mixing molar ratio is 1:6, evenly mixed;

[0075] After the granulation is completed, the particle size of the spherical mixed particles is 0.5-10mm in diameter.

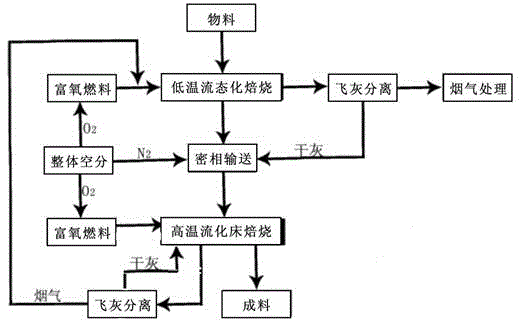

[0076] (2) Roast the particles in a two-stage fluidized roasting system, see figure 2

[0077]Material particles (0.5-10mm) with a moisture content of 6% to 20% enter the low-temperature drying system through the silo and feeding device for low-temperature roasting to remove all moisture on the surface of the particles. In the low-temperature drying system, the ambient air is pressurized by the first combustion-supporting fan and then preheated by the first air preheater and sent to the low-temperature roasting fluidized bed air chamber. When it is necessary to absorb a large amount of heat energy in the process, ...

Embodiment 2

[0096] (1) Fly ash and ammonium sulfate (NH 4 ) 2 SO 4 Mixing granulation, see figure 1

[0097] Add 44.34 tons (NH 4 ) 2 SO 4 , so that fly ash and (NH 4 ) 2 SO 4 The mixing molar ratio is 1:8, evenly mixed;

[0098] After the granulation is completed, the particle size of the spherical mixed particles is 0.5-10mm in diameter.

[0099] (2) Roast the particles in a two-stage fluidized roasting system, see figure 2

[0100] Material particles (0.5-10mm) with a moisture content of 6% to 20% enter the low-temperature drying system through the silo and feeding device for low-temperature roasting to remove all moisture on the surface of the particles. In the low-temperature drying system, the ambient air is pressurized by the first combustion-supporting fan and then preheated by the first air preheater and sent to the low-temperature roasting fluidized bed air chamber. When it is necessary to absorb a large amount of heat energy in the process, start the low-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com