Equipment for processing mechanical processing sump oil

A technology of machining and dirty oil, applied in the direction of mechanical equipment, engine lubrication, engine components, etc., can solve the problems of increased cumbersome operation and increased management difficulty, and achieve simple and reasonable structural design, easy management, and improved integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

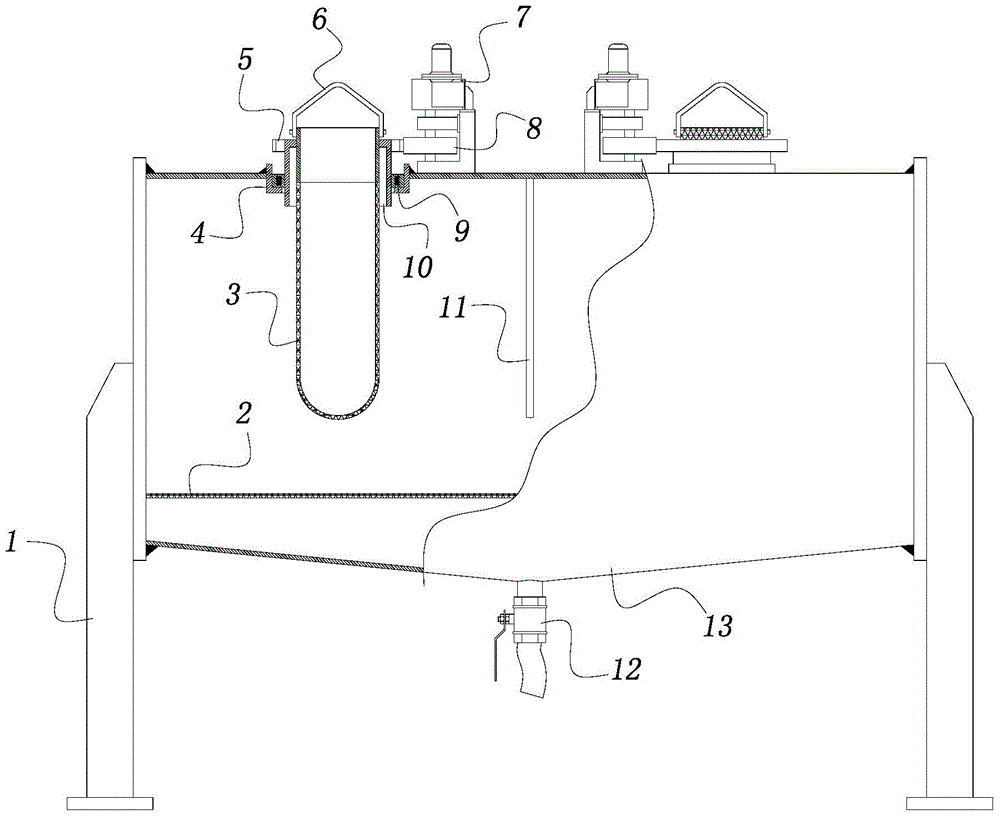

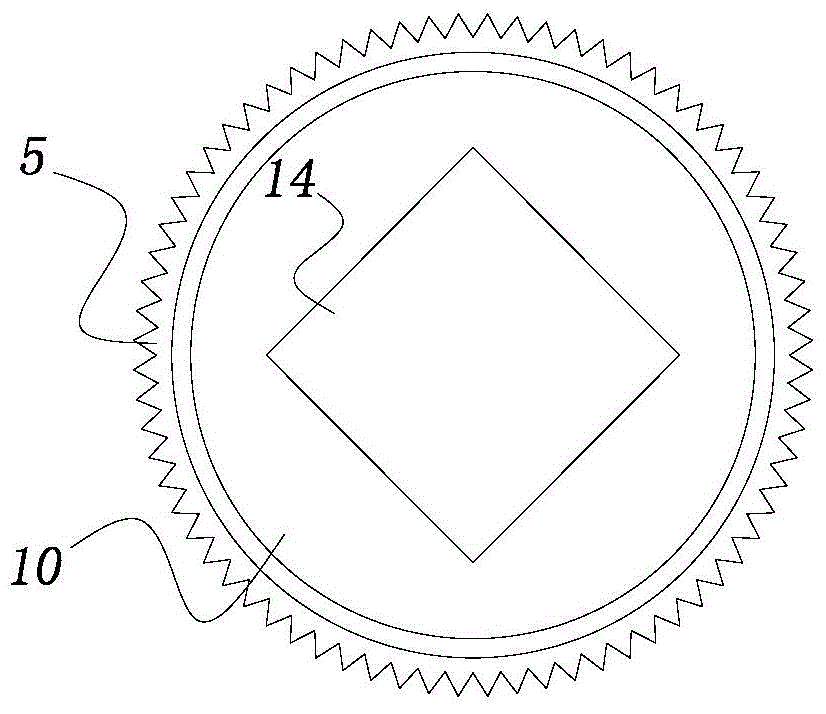

[0012] See figure 1 and figure 2 , the present invention includes a box body 13 supported by a column 1 with a conical bottom, a horizontal filter screen 2 is provided at the bottom of the inner cavity of the box body 13, and an oil discharge valve 12 is installed at the low point of the conical bottom.

[0013] Two sets of left and right centrifugal filter devices are installed on the top of the box body 13 to perform centrifugal filter treatment on the dirty oil collected in the workshop to filter out debris impurities with larger particle sizes, which is equivalent to coarse filter treatment. The dirty oil that has been treated by coarse filtration drops onto the filter screen 2, and in the process of infiltrating and descending from the filter screen 2, the small particle size impurities in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com