Stainless steel pipe three-layer polypropylene anti-corrosion pipe manufacturing equipment and its use method

A stainless steel pipe and manufacturing equipment technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as increasing labor costs, affecting the appearance of anti-corrosion coatings, uneven thickness of PP layers, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

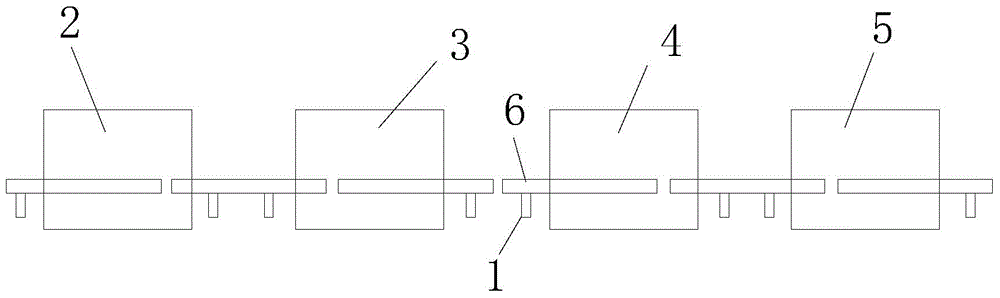

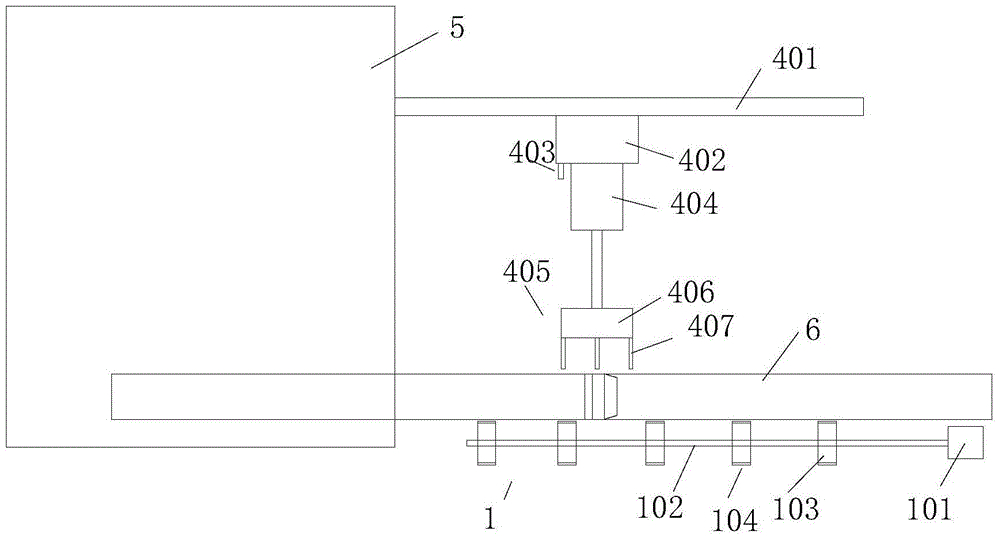

[0029] Embodiment: a kind of manufacturing equipment of stainless steel pipe three-layer polypropylene anticorrosion pipe, as attached figure 1 As shown, it includes a feeding mechanism 1 for conveying stainless steel pipes, and above the feeding mechanism 1, a sandblasting and derusting device 2, a painting device 3, a cutting device 4 and a water cooling device 5 are arranged in sequence;

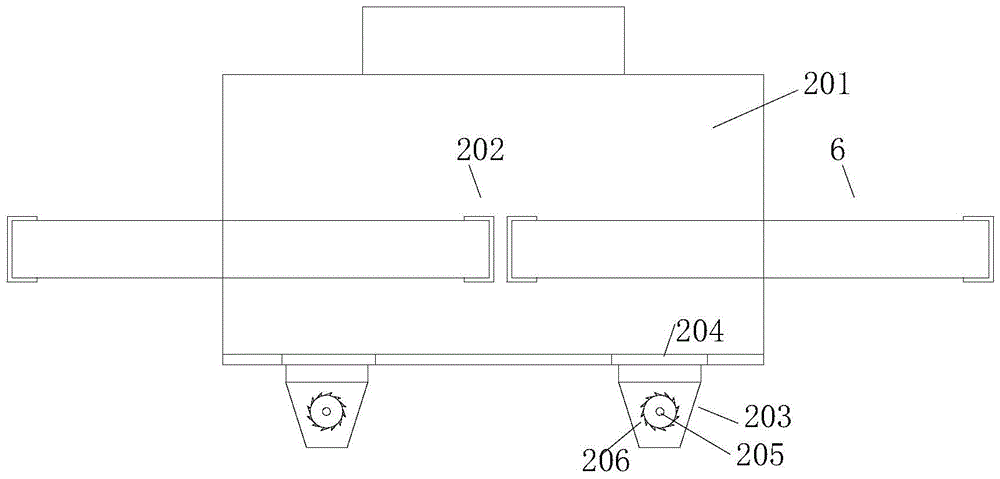

[0030] as attached figure 2 As shown, the described sand blasting and derusting device 2 includes a shot blasting chamber 201, the stainless steel pipe 6 passes through the shot blasting chamber 201, and the two ends of the stainless steel pipe 6 are provided with groove protectors 202, and the groove protectors 202 are polyurethane Pipe body; the below of the shot blasting chamber 201 is provided with a shot blasting device 203, and a through hole 204 is provided between the shot blasting chamber 201 and the shot blasting device 203. Shot blasting wheel 206, the wheel surface of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com