Preparation method of copper conductive ink

A technology of conductive ink and copper salt, applied in inks, household appliances, applications, etc., can solve the problems of unstable copper particles and wide particle size distribution of copper particles, and achieve no chemical toxicity, concentrated particle size distribution, and cheap and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of copper conductive ink, the method comprises the following steps:

[0014] S1. Heating the copper salt aqueous solution to 78-82° C., then adding an aqueous ascorbic acid solution and an aqueous phytic acid solution dropwise at the same time, keeping the temperature at 78-82° C. until the reaction is completed, to obtain a dispersion of copper nanoparticles;

[0015] S2, centrifuging, washing and drying the copper nanoparticle dispersion to obtain copper particles;

[0016] S3. Mixing the copper nanoparticles and the solvent to obtain the copper conductive ink.

[0017] In the preparation method of the copper conductive ink of the present invention, ascorbic acid is used as a reducing agent and a modifier at the same time. The ascorbic acid first provides an active hydrogen to reduce divalent copper ions to zero-valent copper to generate water and half-dehydrogenated ascorbic acid. Half-dehydroascorbic acid can be c...

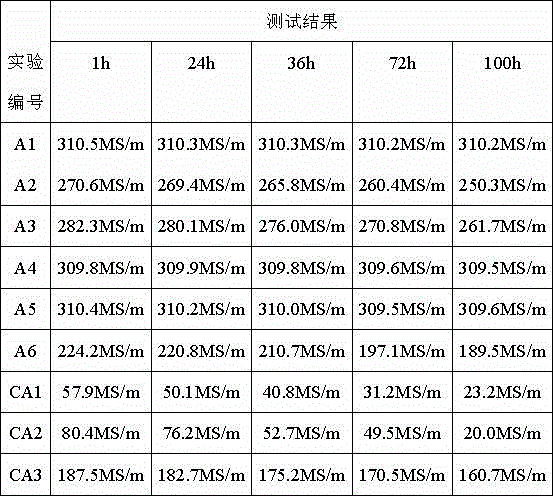

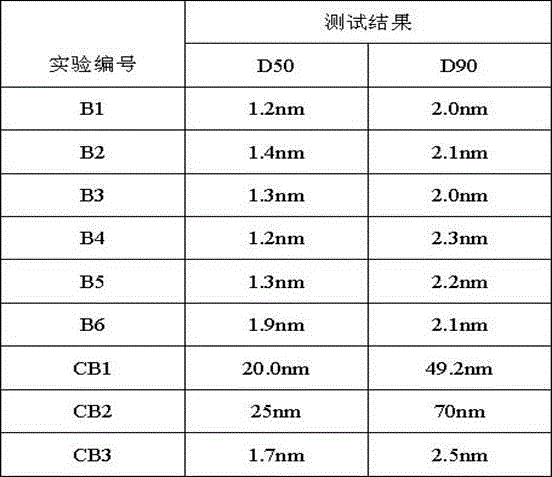

Embodiment 1

[0032] 10mmol of CuCl 2 2H 2 O was dissolved in 50ml of deionized water, the solution was stirred with a magnetic force, and heated to 80°C with an oil bath; at the same time, the CuCl 2 2H 2 Add 50ml, 0.1mol / L ascorbic acid aqueous solution and 5ml, 0.05mol / L phytic acid aqueous solution dropwise evenly in the O solution, and the dropping time is 40min to 60min, and the dropping speed of the two is well controlled. After the reaction is completed, keep the temperature for 30 minutes, and cool naturally to obtain copper nanoparticle dispersion A1 with high dispersion stability.

Embodiment 2

[0034] Prepare copper nanoparticle dispersion liquid A2 according to the method for embodiment 1, difference is: copper salt is copper nitrate, and concentration is 0.05mol / L, and volume is 200ml; The concentration of ascorbic acid aqueous solution is 0.025mol / L, and volume is 40ml, inositol The concentration of the hexaphosphoric acid aqueous solution is 0.0125mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap