Accurate positioning device for corrugated pipe

A precise positioning and corrugated pipe technology, applied in the direction of bridge parts, structural elements, building components, etc., can solve the problems of reduced positioning qualification rate, prone to errors and errors, and reduced accuracy, and achieve efficient and smooth implementation, smooth pipelines, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

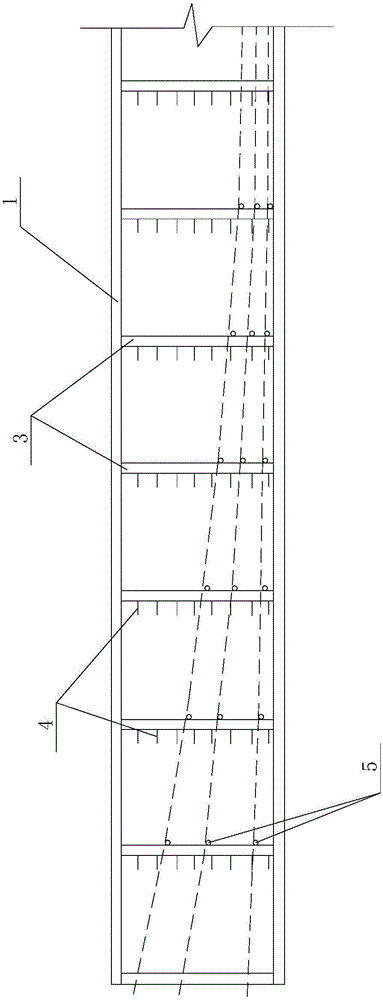

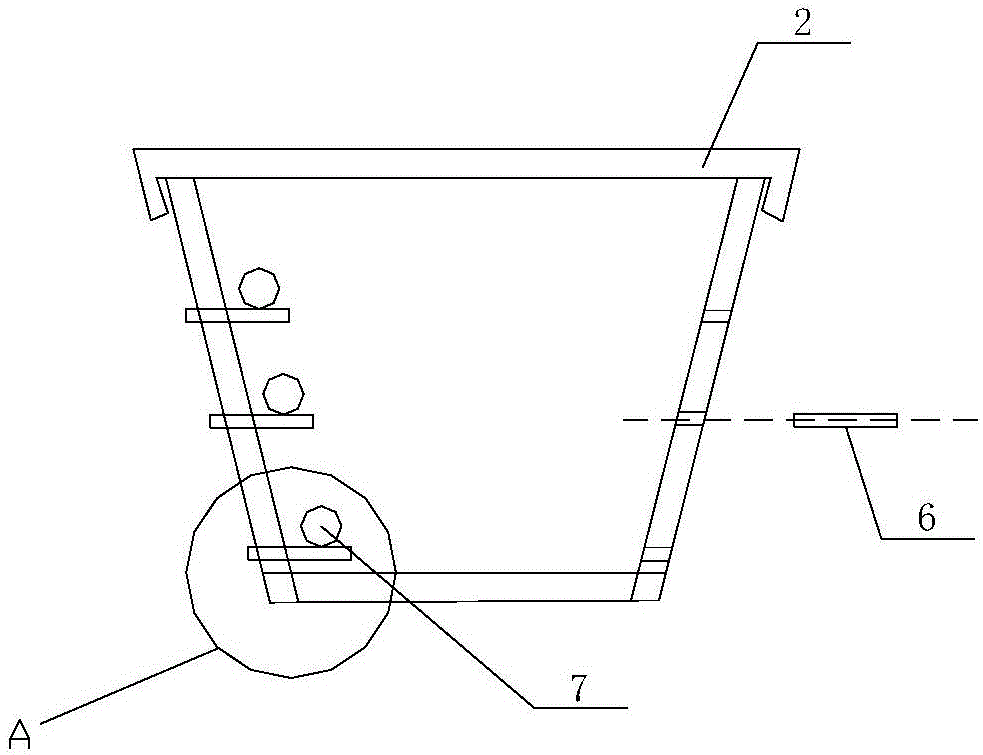

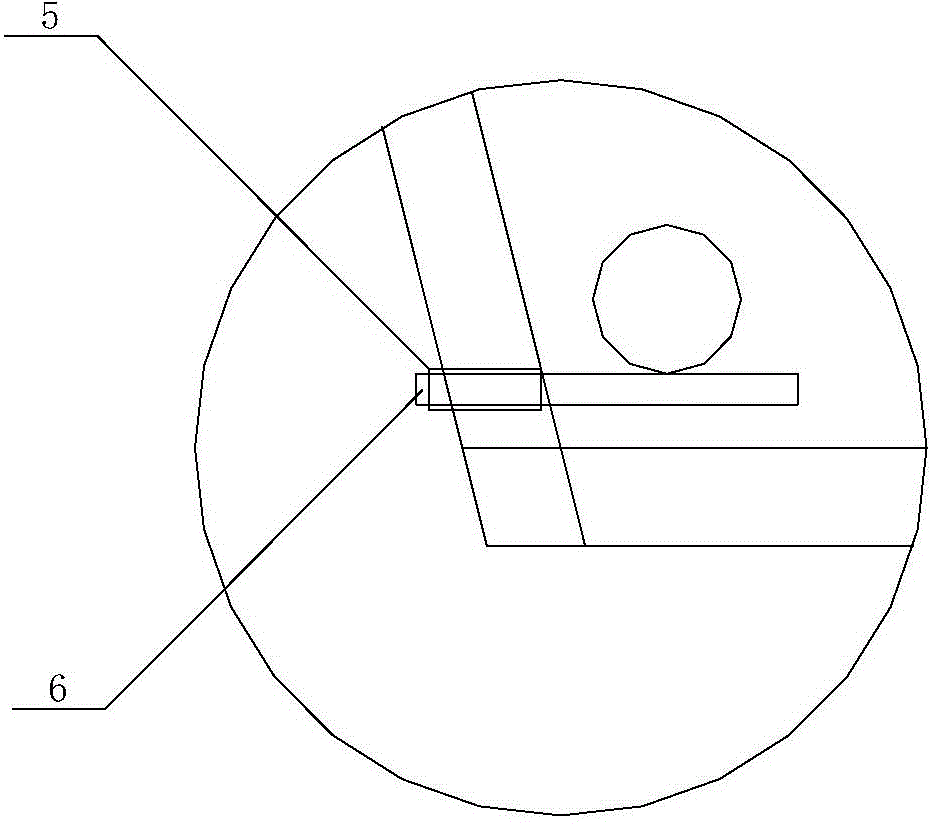

[0013] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: it includes a box girder reinforcement platform formwork 1, a top locking rod 2, a vertical rod 3, a web distribution reinforcement positioning rib 4, a bellows positioning steel pipe 5 and a movable pin 6; Several top locking rods 2 are evenly arranged on the upper part of the box girder steel bar formwork 1, and several vertical bars 3 are evenly arranged on both sides of the box girder steel bar formwork 1, and several vertical bars 3 are evenly arranged on one side of each vertical bar 3. The web distributes reinforcing bar positioning ribs 4, and the other side of the vertical bar 3 is provided with several bellows positioning steel pipes 5, and the inside of the bellows positioning steel pipes 5 is plugged with movable pins 6, and the bellows 7 is placed on the movable pins 6.

[0014] This embodiment adopts the following fixing methods:

[0015] 1. Requirements for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com