Metal wire mesh carrier winding and canning all-in-one machine

A wire mesh carrier and wire mesh technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem that rolling and shelling cannot be completed in one piece, and achieve the effect of reducing equipment, ensuring product quality, and increasing output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

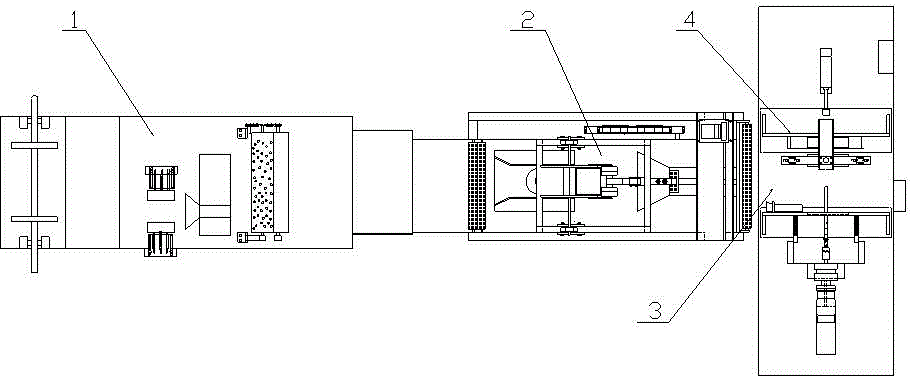

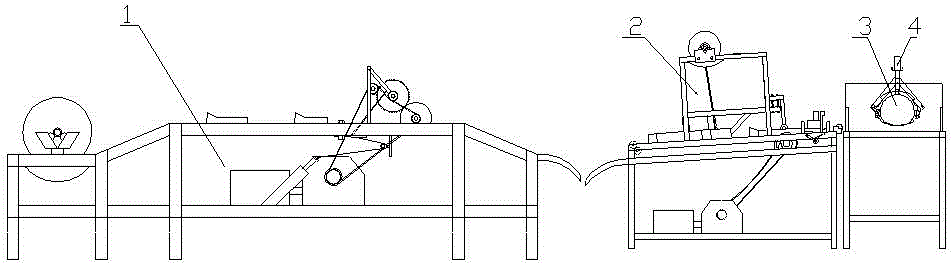

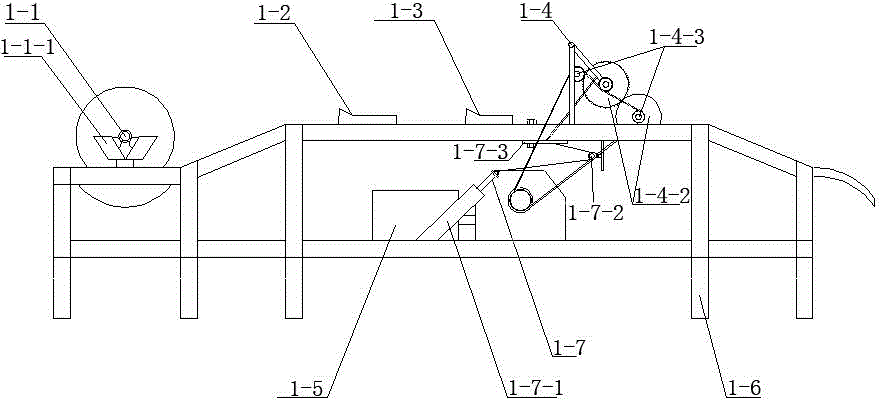

[0016] The present invention will be further explained below in conjunction with the drawings: figure 1 , 2 As shown, the metal wire mesh carrier rolling and casing integrated machine is composed of a stainless steel wire mesh pressing machine 1, a metal mesh clamping platinum sheet device 2, a metal wire mesh rolling machine 3, and a vertical casing machine 4. Its characteristics Lies in: such as image 3 , 4 As shown, the pressing machine base 1-6 of the stainless steel wire mesh pressing machine 1 sequentially arranges the wire mesh hanging rack 1-1, the wire mesh guide 1-2, and the wire mesh preform template from the front to the rear. 1-3. Screen forming press rollers 1-4, press motors 1-5 are arranged at the bottom of press base 1-6 below the screen forming press wheels 1-4, and the cylinder telescopic frame 1-7 is on the wire The bottom of the molding machine base 1-6 under the mesh forming press wheel 1-4 and the wire mesh pre-forming template 1-3; the metal wire mesh ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap