Method of producing water soluble ammonium phosphor nitrate through disc granulation

A technology of ammonium nitrate phosphorus and disk granulation, which is applied to ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc. It can solve the problems of unstable product quality and agglomeration, and achieve large-scale production suitable for industrialization. Production, enhanced fluidity, enhanced strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

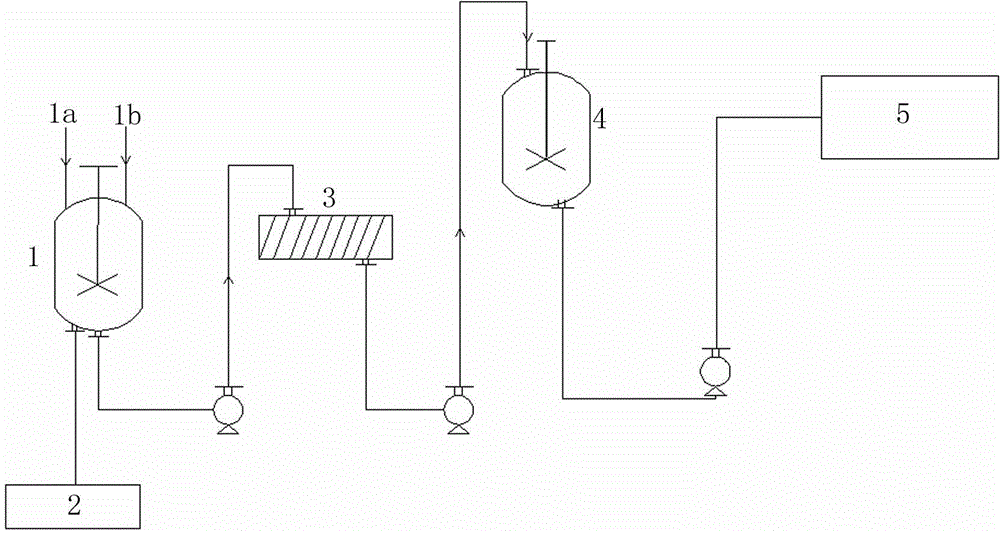

Image

Examples

Embodiment 1

[0012] Example 1 A method for disc granulation to produce fully water-soluble ammonium nitrate phosphorus, comprising the following steps: (1), adding solid ammonium nitrate, solid ammonium dihydrogen phosphate and water to the reactor at a mass ratio of 71:23:3 Heat to dissolve, react at 165°C to obtain molten ammonium nitrate phosphorus, then add the curing agent sodium nitrate, the curing agent sodium nitrate accounts for 2% of the total mass of the mixture after adding the curing agent sodium nitrate, and then evaporate the mixture to a specific gravity of 1.470 g / cm 3 ;

[0013] (2) The concentrated liquid obtained in step (1) enters the cooling tank, stirs and heats up to 100°C, then sends the concentrated liquid into a disc granulator, and granulates through the disc granulator to produce a spherical granular product.

[0014] The purity of solid ammonium nitrate and solid ammonium dihydrogen phosphate is greater than or equal to 99%. To ensure product quality.

Embodiment 2

[0015] Example 2 A method for disc granulation to produce fully water-soluble ammonium nitrate phosphorus, comprising the following steps: (1), adding solid ammonium nitrate, solid ammonium dihydrogen phosphate and water to the reactor at a mass ratio of 75:27:3 Heat to dissolve, react at 165°C to obtain molten ammonium nitrate phosphorus, then add the curing agent sodium nitrate, the curing agent sodium nitrate accounts for 4% of the total mass of the mixture after adding the curing agent sodium nitrate, and then evaporate the mixture to a specific gravity of 1.430g / cm 3 ;

[0016] (2) The concentrated liquid obtained in step (1) enters the cooling tank, stirs and heats up to 110°C, and then sends the concentrated liquid into a disc granulator, and is granulated by the disc granulator to form a spherical granular product.

[0017] The content of solid ammonium nitrate and solid ammonium dihydrogen phosphate is greater than or equal to 99%. To ensure product quality.

Embodiment 3

[0018] Example 3 A method for disc granulation to produce fully water-soluble ammonium nitrate phosphorus, comprising the following steps: (1), adding solid ammonium nitrate, solid ammonium dihydrogen phosphate and water to the reactor at a mass ratio of 73:20:3 Heat to dissolve, react at 165°C to obtain molten ammonium nitrate phosphorus, then add the curing agent sodium nitrate, the curing agent sodium nitrate accounts for 5% of the total mass of the mixture after adding the curing agent sodium nitrate, and then evaporate the mixture to a specific gravity of 1.574g / cm 3 ;

[0019] (2) The concentrated solution obtained in step (1) enters the cooling tank, stirs and heats up to 90°C, then sends the concentrated solution into the disc granulator, and granulates through the disc granulator to produce spherical granular finished products.

[0020] The content of solid ammonium nitrate and solid ammonium dihydrogen phosphate is greater than or equal to 99%. To ensure product q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com