Energy-saving freezer lid

A freezer and transparent technology, applied in lighting and heating equipment, household appliances, household refrigeration equipment, etc., can solve the problems of accelerated frosting on the surface of the evaporator, thickening of the frosting layer, and accelerated wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

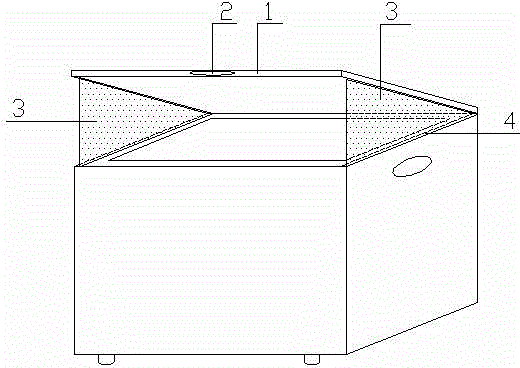

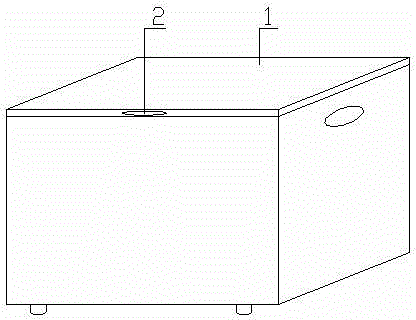

[0008] Such as figure 1 , 2 As shown, there is an oval row of grooved handles on the front of the freezer lid with a groove depth of 5 mm. The left and right sides of the inner surface of the freezer cover are glued with PVC transparent thermal insulation soft curtains at a distance of 10 mm from the cover edge. The transparent thermal insulation soft curtains are a triangular piece of material. The width is 5 mm, the length is the same as the inner net width of the freezer, and the depth is half of the inner net depth of the freezer. When the freezer cover is opened, only the front is connected to the air, and the left and right sides are provided with transparent thermal insulation soft curtains to separate the inside of the freezer from the outside air. When the freezer cover is closed, the transparent thermal insulation soft curtains are inserted into the soft curtain jacks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com