A cellulase-producing Aspergillus niger and its application

A technology of cellulase and Aspergillus niger, applied in the field of halophilic Aspergillus niger and its cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

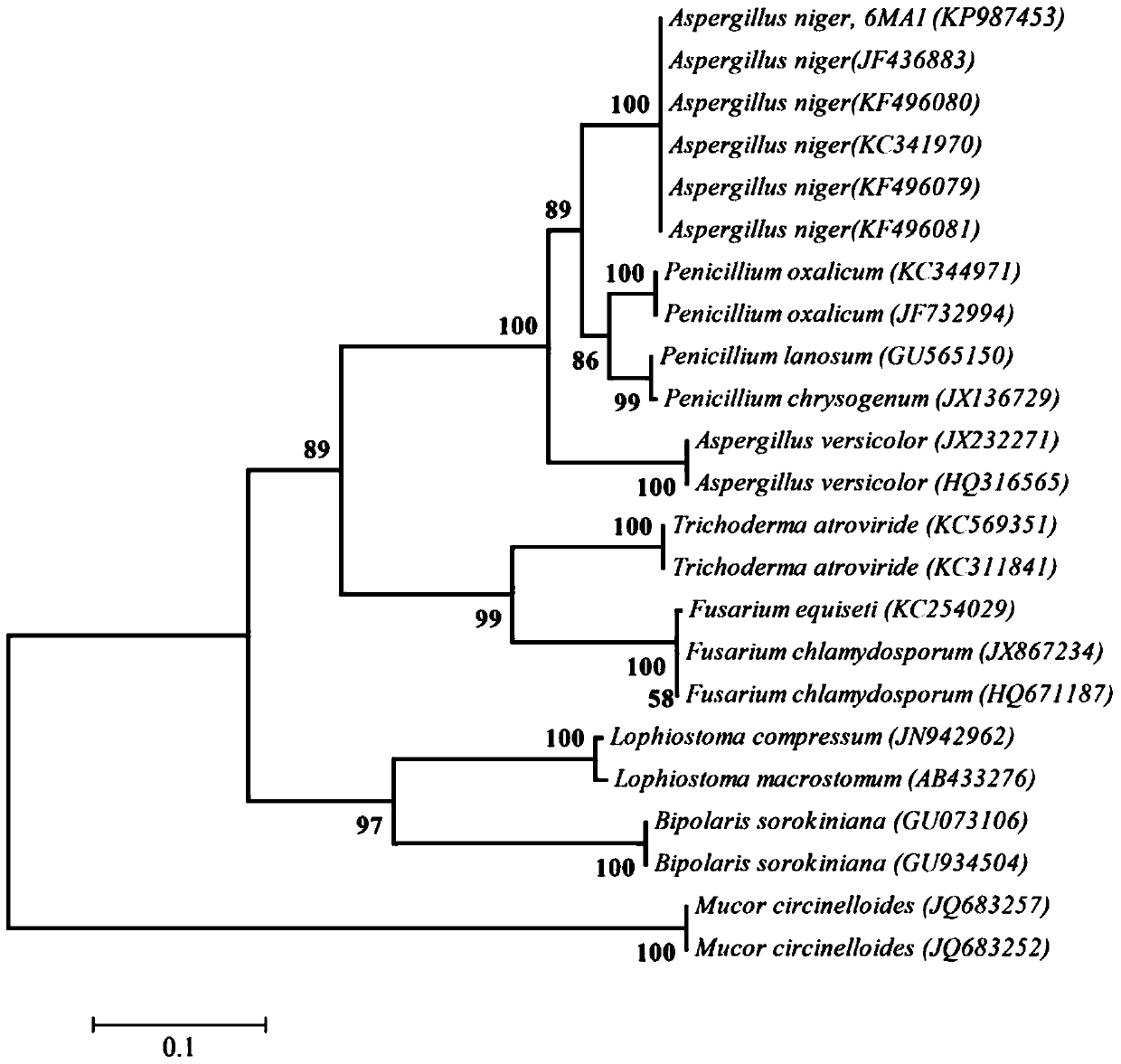

Method used

Image

Examples

Embodiment 1

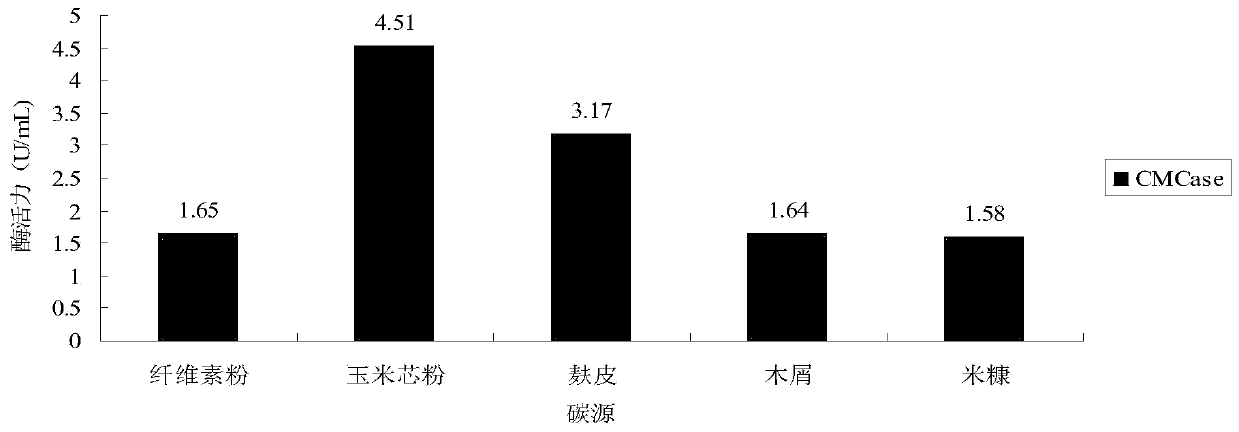

[0054] The screening of the optimal carbon source of embodiment 1 Aspergillus niger producing cellulase fermentation medium

[0055] ① Inoculate the seed solution at 10% inoculum amount in the fermentation medium whose carbon source is corncob powder, bran, cellulose, sawdust, and rice bran, at 28°C, 160r min -1 Conditioned for 72h.

[0056] ② Make the fermentation broth 4000r·min -1 Centrifuge for 10 min to obtain the supernatant crude enzyme solution. Take 1 mL of the crude enzyme solution and add 9 mL of pH 4.8, 0.05 mol / L citric acid buffer to prepare a diluted enzyme solution. Take two 20mL test tubes, add 0.5mL diluted enzyme solution and 1.5mL 0.5% CMC solution to one test tube, add 2.0mL 0.5% CMC solution to the other control tube, and do 3 replicates for each tube of the diluted enzyme solution test tube.

[0057] ③ 50 ℃ water bath for 30 minutes, add 3mL DNS reagent.

[0058] ④Bath in boiling water for 5 minutes, take it out and immediately put it in ice water to ...

Embodiment 2

[0060] The optimal nitrogen source screening of embodiment 2 Aspergillus niger producing cellulase fermentation medium

[0061] ①Determine the optimal carbon source, use (NH4)2SO4, soybean powder, beef extract, yeast extract, and peptone as nitrogen sources, inoculate the seed solution at 10% inoculum in the fermentation medium, 28°C, 160r min -1 Conditioned for 72h.

[0062] 2.-5. steps are the same as in Example 1. To draw a histogram of enzyme activity values against different nitrogen sources, see Figure 4 , the study of enzymatic properties showed that the best nitrogen source for the strain to produce cellulase fermentation medium was peptone with a mass fraction of 0.5%.

Embodiment 3

[0063] The optimal temperature screening of embodiment 3 Aspergillus niger producing cellulase fermentation culture

[0064] ①Determine the optimal carbon source and nitrogen source medium, inoculate the seed solution in the fermentation medium at 10% inoculation amount, and inoculate them at 24°C, 26°C, 28°C, 30°C, 32°C, 160r·min -1 Conditioned for 72h.

[0065] 2.-5. steps are the same as in Example 1. To draw a line graph of enzyme activity values against different temperatures, see Figure 5 , the study of enzymatic properties showed that the optimum temperature for the strain to produce cellulase fermentation medium was 28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com