Heat-curable composition

A technology of thermosetting and composition, applied in the direction of coating, etc., can solve the problems of heat resistance, transparency and sputtering resistance unknown, and achieve excellent heat resistance, high transparency, and excellent sputtering resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] Hereinafter, the present invention will be further described with reference to examples, but the present invention is not limited to these examples.

Synthetic example 1

[0150] [Synthesis Example 1] Synthesis of Silicone Polymer (A1)

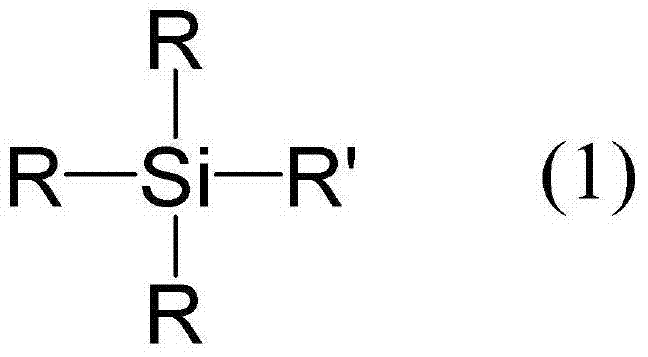

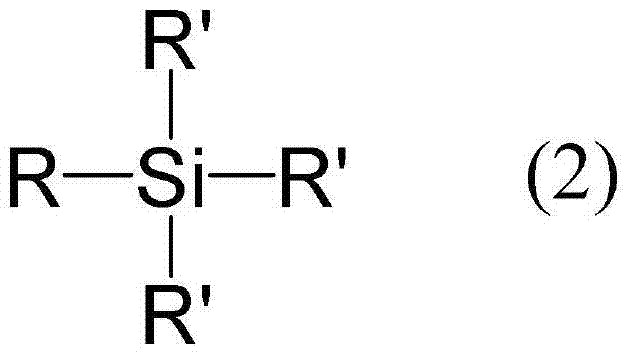

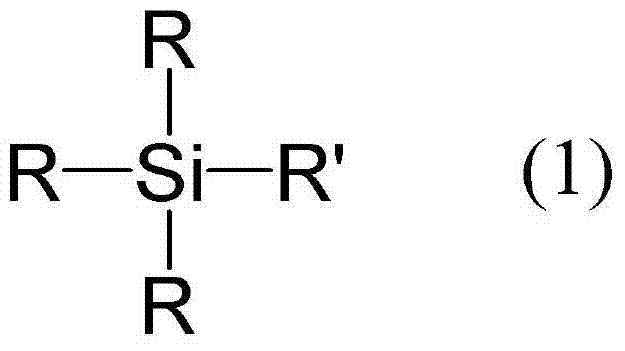

[0151] In a four-necked flask with a stirrer, drop into diethylene glycol methyl ethyl ether as a reaction solvent, trimethylmethoxysilane as a monofunctional silane represented by general formula (1) by the following weight, as Trimethoxymethylsilane and trimethoxyphenylsilane, which are trifunctional silanes represented by the general formula (2), were then added dropwise a mixed solution of 0.19 g of formic acid, 0.08 g of phosphoric acid, and 5.81 g of water. Then, it heated at 80 degreeC for 1 hour, then distilled off for 2.5 hours to remove a low molecular weight component, and then distilled off at 130 degreeC for 2 hours, and obtained the 80 weight% solution of the siloxane polymer (A1). The total of the low boiling point components removed by distillation was 21.07g.

[0152]

[0153] The above solution was cooled to room temperature (25° C.), a part of the solution was sampled, and the weight avera...

Synthetic example 2

[0154] [Synthesis Example 2] Synthesis of Silicone Polymer (A2)

[0155] Use triethoxymethylsilane instead of trimethoxymethylsilane as the trifunctional silane represented by the general formula (2), except that the following weights are added to the same components as in Synthesis Example 1. 1 The reaction was carried out under the same conditions to obtain an 80% by weight solution of the siloxane polymer (A2). GPC analysis of the siloxane polymer (A2) thus obtained revealed that the weight average molecular weight (Mw) was 4,000. In addition, the number ratio of the methyl group to the phenyl group in the siloxane polymer (A2) was 2.0.

[0156]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com