Frame sealing adhesive composite, display panel and display device

A technology for display panels and sealants, applied in adhesives, instruments, optics, etc., can solve the problems of puncture, product yield drop, impact effect of sealant, etc., to improve puncture resistance, improve product yield, reduce impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

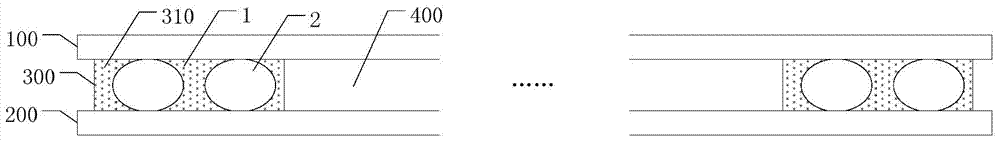

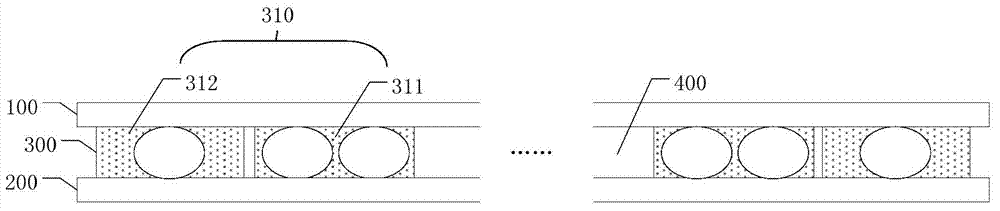

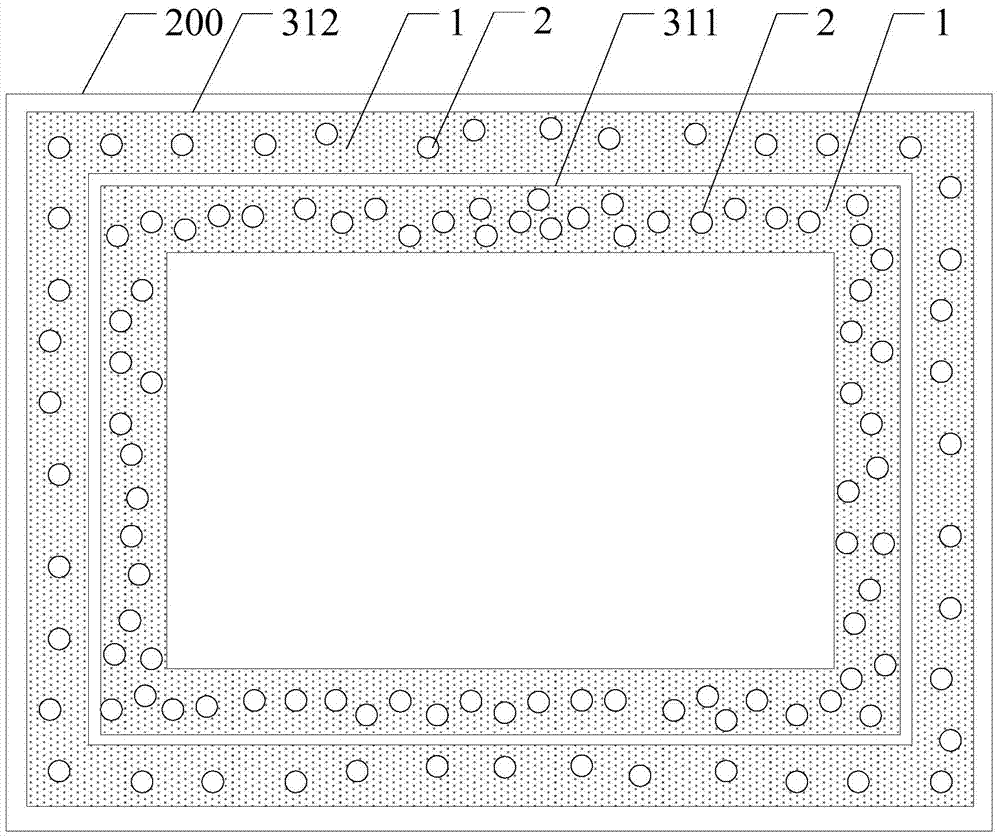

[0026] An embodiment of the present invention provides a frame sealing compound, including a frame sealing compound, and the frame sealing compound also includes an elastic body. When the frame sealing compound is used for the joining of two substrates, the The body is pressed by the two substrates to form a barrier structure.

[0027] In the frame sealing composition provided by the embodiment of the present invention, by adding elastomers to the sealing compound, when the sealing compound is used for the combination of two substrates, the elastic body is squeezed by the two substrates to form a barrier structure, the barrier structure formed by the elastomer can effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap