A kind of conductive paste for solar cell

A technology of conductive paste and conductive metal powder, which is applied in the direction of conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials, can solve the problems of low photoelectric conversion efficiency of batteries, and achieve the improvement of photoelectric conversion efficiency and photoelectric conversion. The effect of high efficiency and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

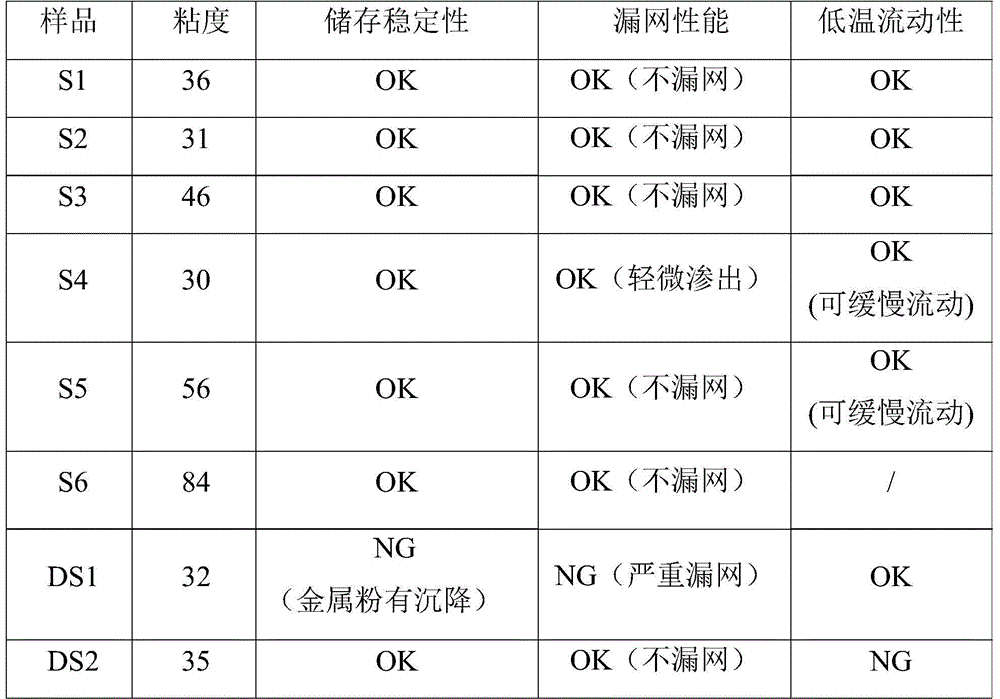

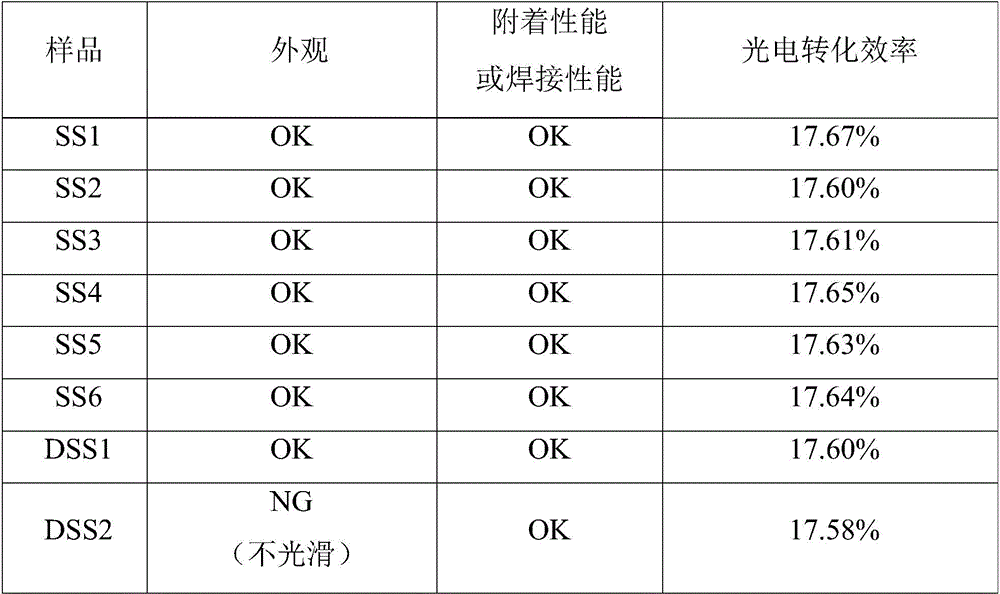

Examples

Embodiment 1

[0036] (1) Preparation of organic carrier

[0037] According to the mass ratio, butyl carbitol: terpineol: butyl carbitol acetate=70:20:10 is mixed evenly to form the organic solvent used for the conductive paste. Dissolve 5 parts (parts by weight, the same below) of ethyl cellulose with an ethoxy content of 49.6% by weight and a viscosity specification of 100mPa·s, and 1.5 parts of cetyl alcohol in 93.5 parts of an organic solvent, and heat to 100°C , Stir for 1h, make it fully dissolved, and cool to obtain an organic vehicle.

[0038] (2) Preparation of conductive paste

[0039] Put 23.5 parts of the organic carrier obtained in step (1) into the stainless steel tank of the high-speed disperser, and add 1.5 parts of glass powder for aluminum conductive paste (model V2027, PbO-B 2 o 3 -SiO 2 series of glass powders, the glass powders used in the following examples to prepare aluminum conductive pastes are the same), stir evenly; then add 75 parts of spherical aluminum powd...

Embodiment 2

[0041] (1) Preparation of organic carrier

[0042] According to the mass ratio, butyl carbitol: terpineol: butyl carbitol acetate=70:20:10 is mixed evenly to form the organic solvent used for the conductive paste. Dissolve 4 parts of ethyl cellulose with an ethoxy content of 51.0% by weight and a viscosity specification of 150 mPa·s, and 1 part of cetyl alcohol in 95 parts of an organic solvent, heat to 90 ° C, stir for 2 hours, and make it fully Dissolved and cooled to obtain an organic vehicle.

[0043] (2) Preparation of conductive paste

[0044] Put 29.5 parts of the organic carrier obtained in step (1) into the stainless steel tank of the high-speed disperser, add 0.5 parts of glass powder for aluminum conductive paste while stirring, and stir evenly; then add 70 parts of spherical aluminum powder, and the aluminum powder is divided into Add three times, stir well after each addition, and then add the next time; after all the addition is completed, stir at a high speed ...

Embodiment 3

[0046] (1) Preparation of organic carrier

[0047] Take butyl carbitol according to the mass ratio: butyl carbitol acetate=80:20 and mix evenly to form the organic solvent used for the conductive paste. The content of 4.5 parts of ethoxy groups is 53.0% by weight, and the viscosity specification is ethylcellulose of 200mPa·s, 3 parts of alkyd resin (brand is AK2010), 5 parts of cetyl alcohol, dissolve in 87.5 parts of organic solvents, Heat to 120°C, stir for 0.5h to fully dissolve, and cool to obtain an organic carrier.

[0048] (2) Preparation of conductive paste

[0049] Put 20 parts of the organic carrier obtained in step (1) into the stainless steel tank of the high-speed disperser, add 3 parts of glass powder for aluminum conductive paste while stirring, and stir evenly; then add 77 parts of spherical aluminum powder, and the aluminum powder is divided into Add three times, stir well for each addition, and then add the next time; after all the addition is completed, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com