Intelligent cornstalk leaf stripping mechanism

A corn stalk and leaf peeling technology, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of easily damaged impact parts, complex structure, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

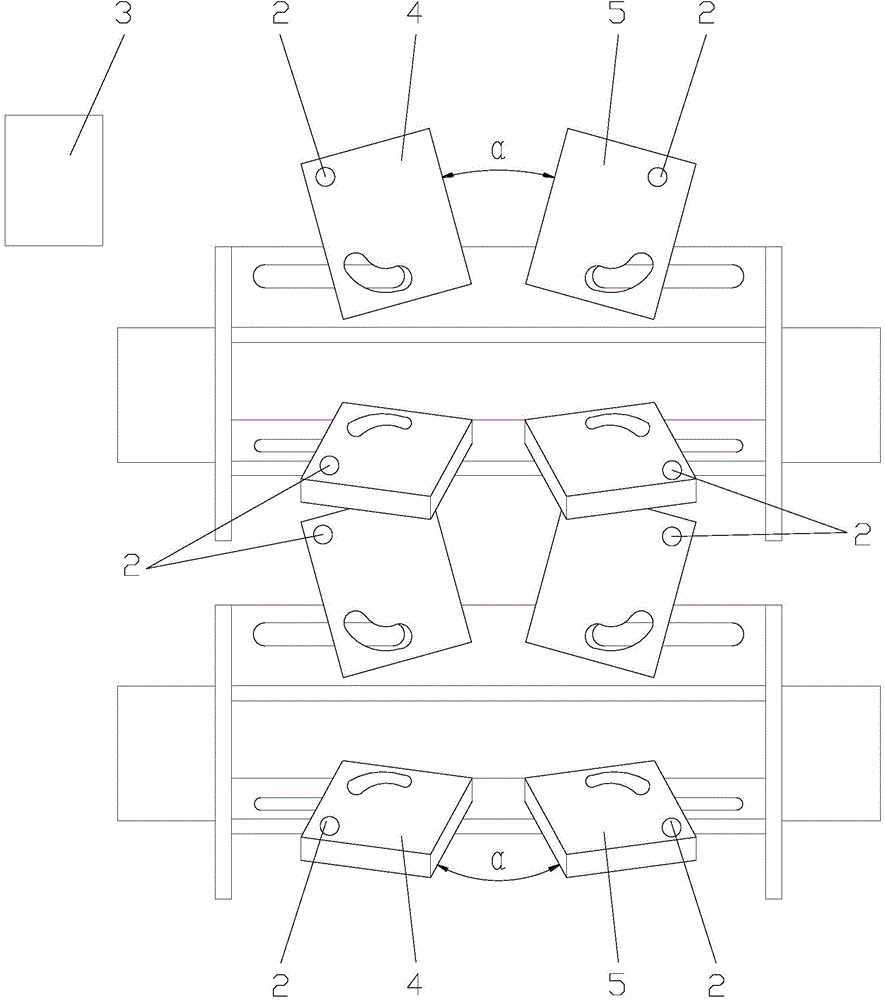

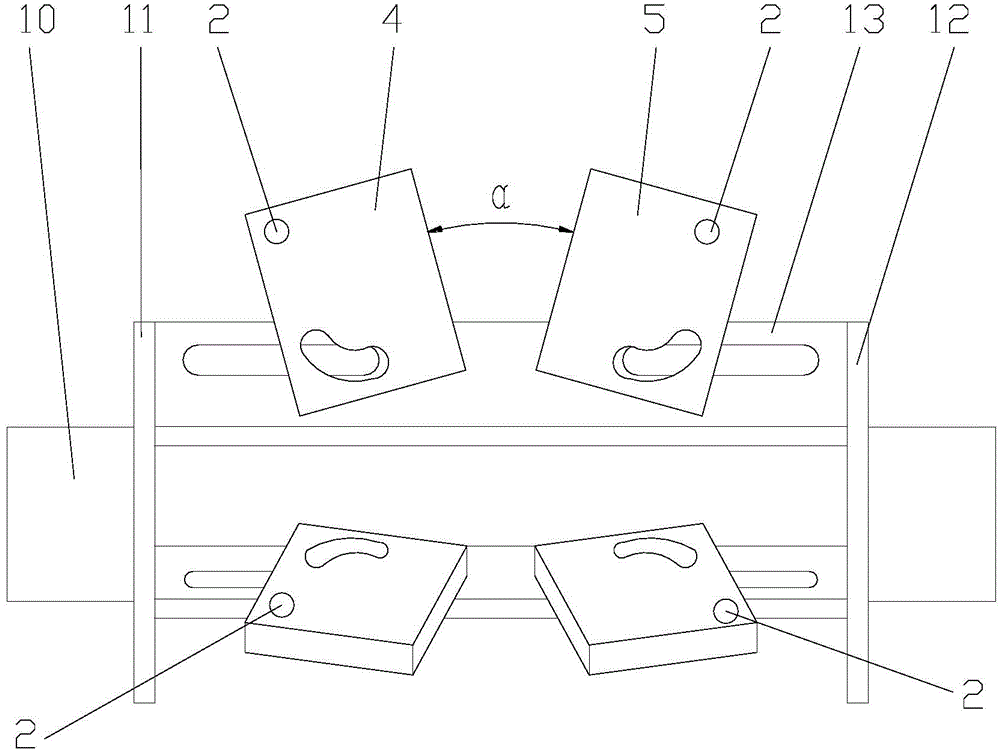

[0014] like figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of an intelligent corn stalk peeling mechanism proposed by the present invention; figure 2 It is a structural schematic diagram of a peeling roller in an intelligent corn stalk leaf peeling mechanism proposed by the present invention.

[0015] refer to figure 1 , figure 2 , an intelligent corn stalk leaf stripping mechanism proposed by the present invention, including a set of leaf stripping rollers rotating at a constant speed in reverse, an infrared sensor 2 and a control device 3, and three pairs of first leaf stripping plates 4 are installed on each leaf stripping roller 1 , the second leaf stripping plate 5, three pairs of the first leaf stripping plate 4 and the second leaf stripping plate 5 on each leaf stripping roller 1 are staggered, and the first leaf stripping plate 4 and the second leaf stripping plate 5 are all provided with An infrared sensor 2 for sensing corn stalk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com