Electrical box spot welding device

A technology of spot welding device and electrical box, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency and easy spot deviation, and achieve the effects of improving production efficiency, improving quality and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

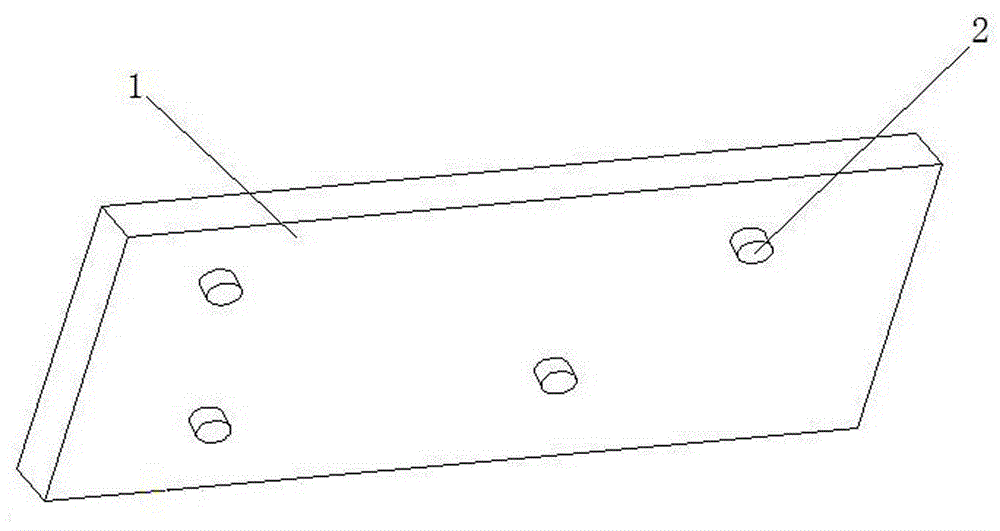

[0007] see figure 1 , this specific embodiment adopts the following technical scheme: it includes a frame body 1, and a plurality of positioning convex hulls 2 are arranged on the frame body 1, the direction of the convex hull 2 is perpendicular to the paper surface inward, and the radius of the convex hull 2 is is 2.75mm. By increasing the positioning convex hull, the matching mode between parts is changed from no positioning to the positioning of the convex hull and the hole. The size of the radius of the convex hull can play a positioning role without hindering the welding function of the components, and the positioning is accurate. , the production efficiency has been significantly improved, and the quality has been improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap