A kind of flexible epoxy anti-corrosion primer and preparation method thereof

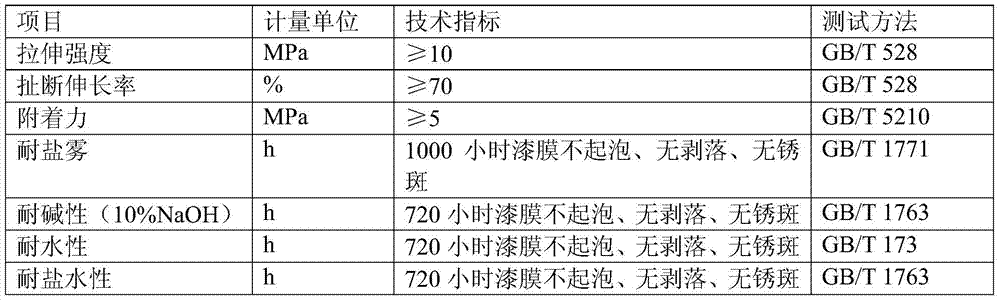

A flexible epoxy and anti-corrosion technology, applied in the field of coatings, can solve the problems of small elongation at break, prone to cracking, affecting the anti-corrosion effect, etc., to improve adhesion, anti-corrosion performance, and elongation at break improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of flexible epoxy anticorrosion primer, comprising the following steps:

[0026] (1) Preparation of component A: Add epoxy resin, modified epoxy resin, dispersant, defoamer, anti-settling agent and silane coupling agent into the organic solvent, stir and disperse evenly, then add pigments and fillers and anti-settling agents in sequence Erosion filler; grind the dispersed slurry into a grinder until the slurry fineness reaches 60 μm; add flake filler, disperse evenly, use filter cloth to filter and package, and obtain component A;

[0027] (2) Preparation of component B: Add the modified amine epoxy curing agent into the organic solvent, stir evenly, filter and pack with filter cloth, and then obtain component B.

Embodiment 1

[0029] A flexible epoxy anti-corrosion primer, including A component and B component, the A component is composed of the following components by weight percentage: 40% epoxy resin, 0.5% fumed silica, 0.5% dispersant %, defoamer 1%, epoxy-containing silane coupling agent 1%, mica 8%, ion exchange antirust pigment 10%, iron oxide red 10%, modified polyethylene glycol diglycidyl ether 9 %, toluene 20%; the B component is composed of the following components by weight percentage: modified polyether amine epoxy curing agent 70%, toluene 30%; the weight of A component and B component is mixed during use The ratio is 4:1.

[0030] A preparation method of flexible epoxy anticorrosion primer, comprising the following steps:

[0031] (1) Preparation of component A: Add epoxy resin, modified polyethylene glycol diglycidyl ether, dispersant, defoamer, fumed silica and silane coupling agent containing epoxy group to the organic solvent, Stir and disperse evenly, then add iron oxide red a...

Embodiment 2

[0041] A kind of flexible epoxy anticorrosion primer, comprises A component and B component, and described A component is made up of following components by weight percentage: epoxy resin 20%, organic bentonite, 2%, dispersant 0.1% , defoaming agent 0.85%, epoxy-containing silane coupling agent 0.05%, mica ash 1%, aluminum tripolyphosphate 30%, anatase titanium dioxide 5%, polypropylene glycol diglycidyl ether 4%, positive 20% butanol, 17% isobutanol; the B component is composed of the following components by weight percentage: 60% modified polyetheramine epoxy curing agent, 40% n-butanol; The weight mixing ratio with B component is 4:1.

[0042] A preparation method of flexible epoxy anticorrosion primer, comprising the following steps:

[0043] (1) Preparation of component A: Add epoxy resin, polypropylene glycol diglycidyl ether, dispersant, defoamer, organic bentonite, and silane coupling agent containing epoxy groups into the organic solvent, stir and disperse evenly, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com