Oil pumping unit polish rod force measuring device

A technology of force measuring device and pumping unit, which is applied in the measurement and measurement of the property force of piezoelectric devices, boreholes/well components, etc., and can solve problems such as damage to force measuring devices, affecting test accuracy, and easy unbalanced loads , to achieve the effect of reasonable structure, high test accuracy and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

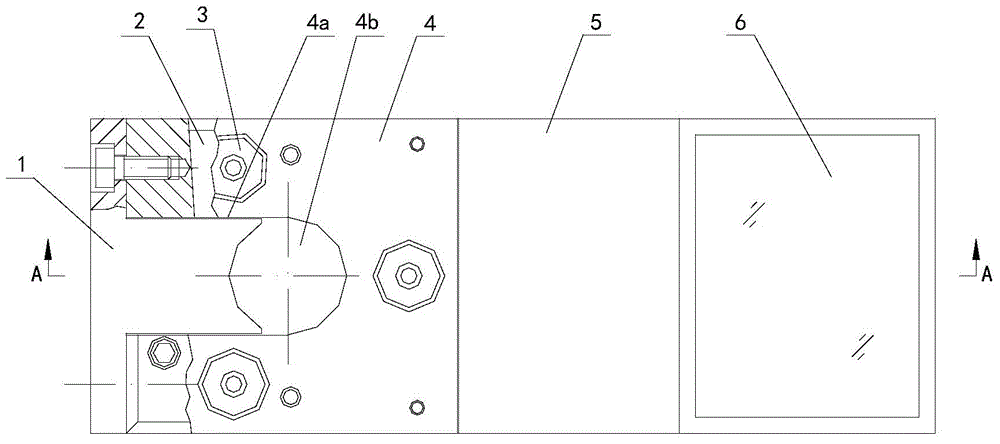

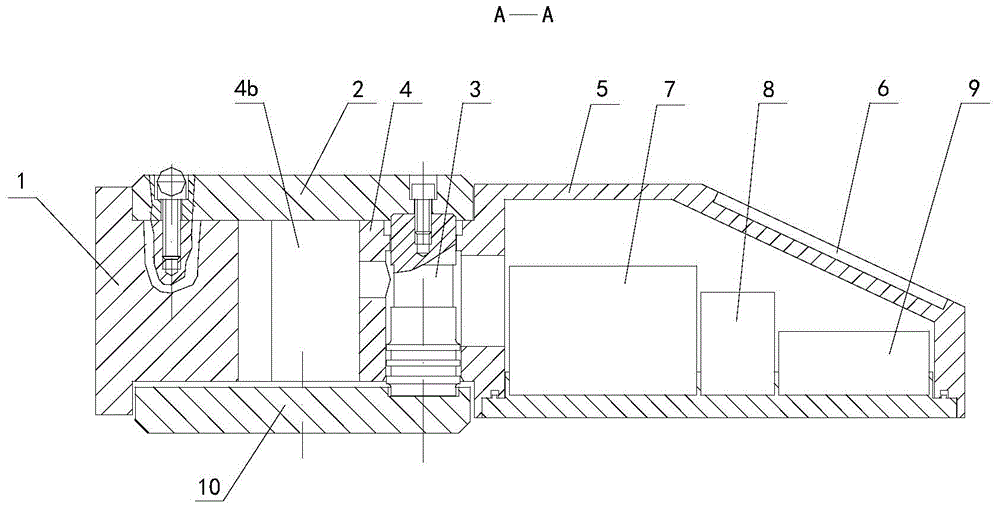

[0010] see figure 1 , figure 2

[0011] The polished rod force measuring device of the pumping unit provided by the present invention has a carrier 4 with a "U"-shaped notch 4a on the carrier 4, and a stopper 1 is installed on the carrier 4, and the stopper 1 and the "U"-shaped notch 4a Cooperate to form the mounting hole 4b, the carrier 4 is connected with the housing 5, the housing 5 and the carrier 4 are integrated, the circuit board 7, the battery 9 and the wireless transmitter 8 are arranged in the housing 5, and the strain relief is installed on the carrier 4. Column 3, the strain gauge is attached to the strain column 3, the strain gauge, the battery 9 and the wireless transmitter 8 are connected to the circuit board 7, there are three strain columns 3, and the three strain columns 3 penetrate into the carrier 4 and Arranged around the installation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com