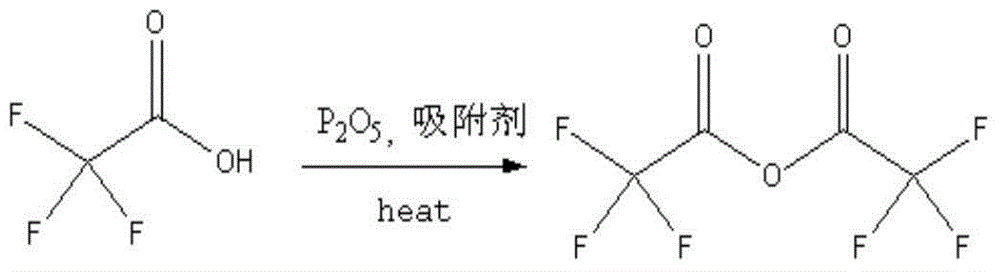

Method for preparing trifluoroacetic anhydride

A technology of trifluoroacetic anhydride and trifluoroacetic acid, applied in the field of preparing trifluoroacetic anhydride, can solve the problems of low yield, poor reaction state, difficult recovery or processing, etc., and achieves safe operation, cheap and easy-to-obtain raw materials, and economical high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a dry 500ml reaction flask, put (17.0g, 0.12mol) white solid powder phosphorus pentoxide, and 10.0g activated carbon that was previously dried at 100-130°C, and add 150ml of toluene dried over anhydrous sodium sulfate Solvent, after mixing and dispersing evenly under mechanical stirring, slowly drop (34.0g, 0.298mol) trifluoroacetic acid, and slowly raise the temperature to reflux, react for 1.5h, and distill under normal pressure to obtain the front fraction at 39-50°C 28.6g, and the obtained front fraction was rectified by a rectifying column to obtain 23.2g of a reagent-grade product at 39-40.5°C, with a yield of 74.12%. Then continue to heat up and distill to collect 143.3g of the back cut above 50°C, the collected back cut can be recycled for the next reaction, the residue after the reaction contains unreacted phosphorus pentoxide solid, drop water or phosphoric acid aqueous solution 150ml, After the reactor is cooled, the by-product phosphoric acid aqueous solu...

Embodiment 2

[0024] In a dry 500ml reaction bottle, put (34.0g, 0.24mol) white solid powder phosphorus pentoxide, and 10.0g of activated silica gel at 100-130°C in advance, and add 150ml of anhydrous calcium chloride dried Xylene (a mixed solvent of o-, m-, and p-xylene), after mixing and dispersing uniformly under mechanical stirring, slowly drip (34.0g, 0.298mol) trifluoroacetic acid, and slowly heat up to reflux, react for 2h, usually Distilled under reduced pressure to obtain 30.2 g of the front fraction at 39-50° C., and rectify the obtained front fraction through a rectification column to obtain 25.7 g of a reagent-grade product at 39-40.5° C., with a yield of 82.11%. Then continue to heat up and distill to collect 137.5 g of the back cut above 50°C, the collected back cut can be recycled for the next reaction, the residue after the reaction contains unreacted phosphorus pentoxide solid, drop water or phosphoric acid aqueous solution 300ml, After the reactor is cooled, the by-product...

Embodiment 3

[0026] In a dry 500ml reaction flask, put (102.0g, 0.72mol) white solid powder phosphorus pentoxide, and 10.0g of activated acidic alumina which was previously dried at 100-130°C, add 150ml of o-xylene solvent, after mixing and dispersing evenly under mechanical stirring, slowly drop (34.0g, 0.298mol) trifluoroacetic acid, and slowly raise the temperature to reflux, react for 2h, and distill under normal pressure to obtain a temperature of 39-50°C 28.1 g of the first cut of the obtained first cut was rectified by a rectification column to obtain 22.1 g of a reagent-grade product at 39-40.5 ° C, and the yield was: 70.60%. Then continue to heat up and distill to collect 153.3 g of the back cut above 50°C, the collected back cut can be recycled for the next reaction, the residue after the reaction contains unreacted phosphorus pentoxide solid, drop water or phosphoric acid aqueous solution 600ml, After the reactor is cooled, the by-product phosphoric acid aqueous solution is reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com