A method for preparing porous electrode with high specific surface area

A high specific surface area, porous electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large environmental pollution of chemical solutions, low preparation efficiency, low repetition rate, etc., to achieve shortened preparation cycle, high preparation efficiency, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

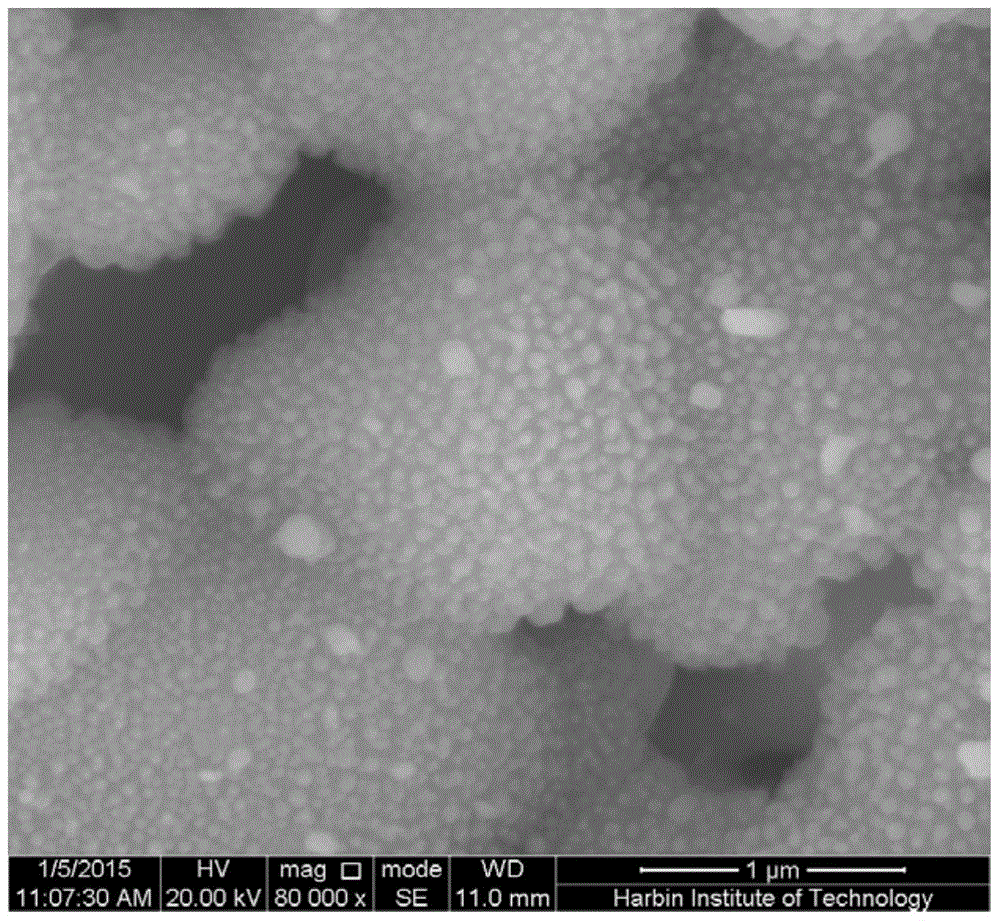

[0023] Specific Embodiment 1: This embodiment is a method for preparing a porous electrode with a high specific surface area, which is completed according to the following steps:

[0024] 1. Hang the porous electrolyte / dielectric and the catalyst target on the sample holder of the pulse plasma multi-component co-infiltration furnace, then evacuate the pulse plasma multi-component co-infiltration furnace to a vacuum degree of 10Pa ~ 30Pa, and then put the pulse plasma The multi-component co-infiltration furnace is kept at a vacuum of 10Pa to 30Pa and a DC voltage of 500V to 700V for 10min to 30min;

[0025] 2. ①. Inject H into the pulse plasma multi-component co-infiltration furnace 2 , and then evacuate the pulse plasma multi-component co-infiltration furnace at the same time, so that the pressure in the pulse plasma multi-component co-infiltration furnace is 50Pa ~ 100Pa, and then when the pressure is 50Pa ~ 100Pa and H 2 Keep the pulse plasma multi-component co-infiltration...

specific Embodiment approach 2

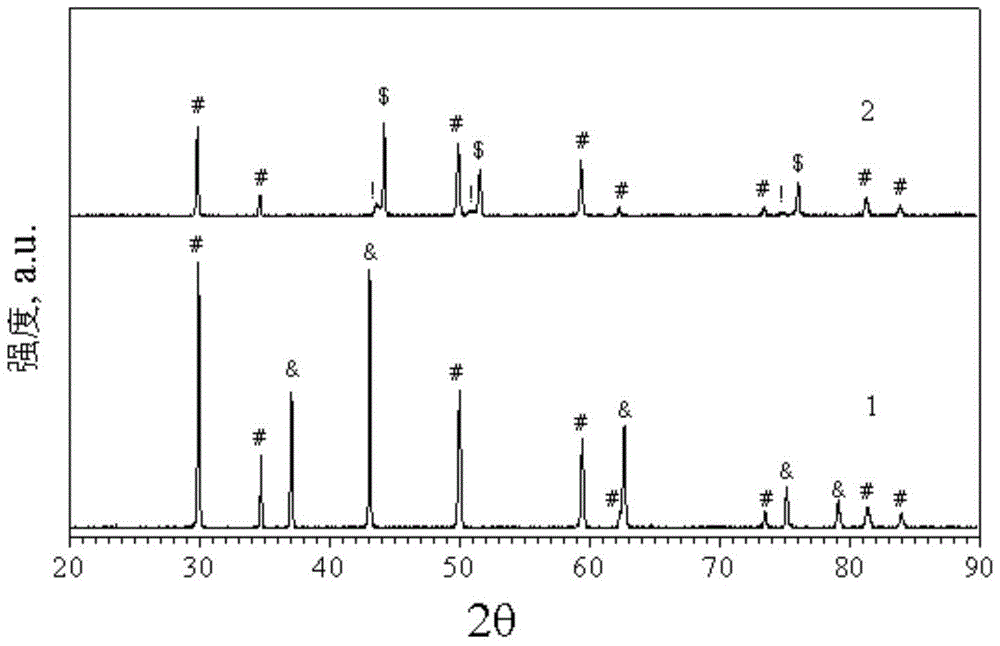

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the porous electrolyte / dielectric described in step 1 is porous yttrium-stabilized zirconia, porous YSZ / NiO composite, porous samarium-doped ceria or porous al 2 o 3 / SiO 2 Complex. Others are the same as the first embodiment.

[0038] The porous YSZ / NiO composite described in this embodiment is formed by mixing porous YSZ and porous NiO in any proportion; the porous Al 2 o 3 / SiO 2 Composite is porous Al 2 o 3 and porous SiO 2 Mixed in any proportion.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the thickness of the porous electrolyte / dielectric described in step 1 is 0.5 mm to 1 mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com