Laminated punched sheet metal electronic enclosure/shield with integrated gaskets

A technology of shielding and lamination, which is applied in the direction of metal casings, electrical equipment casings/cabinets/drawers, electrical components, etc., and can solve problems such as increased production costs and large costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

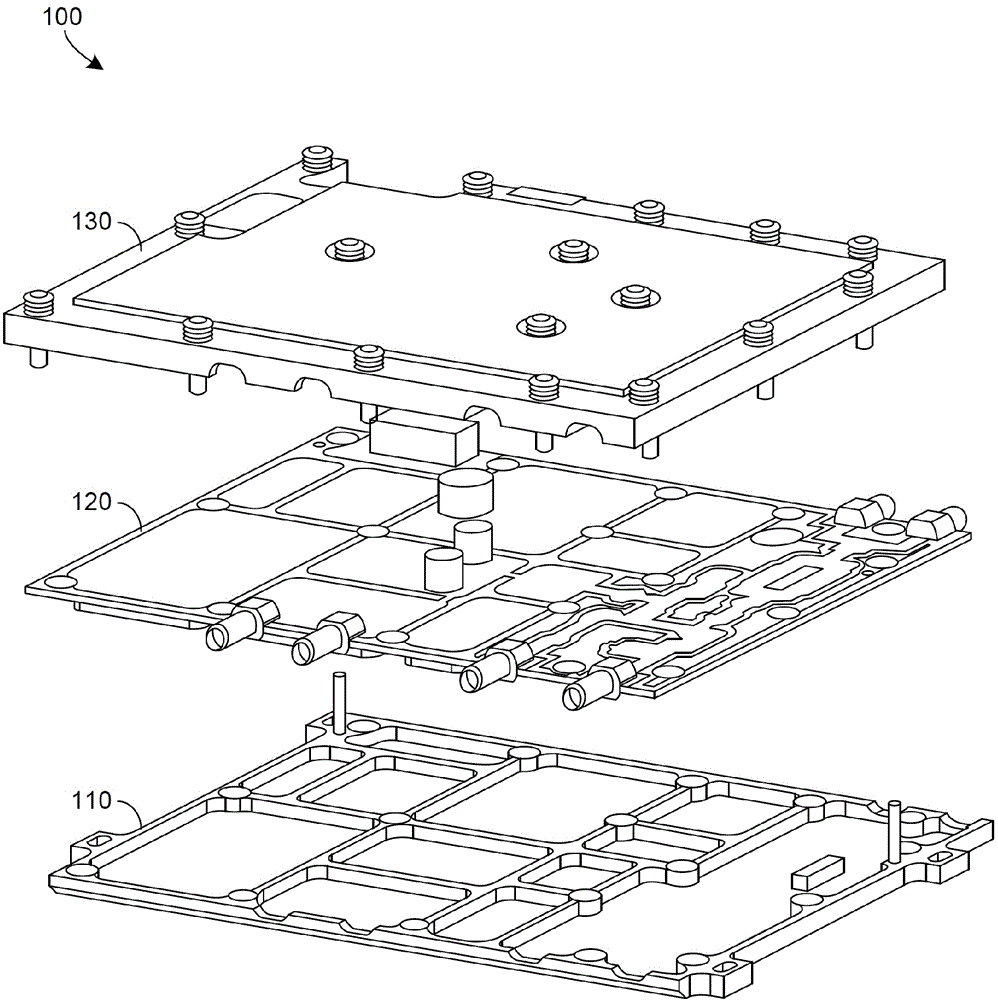

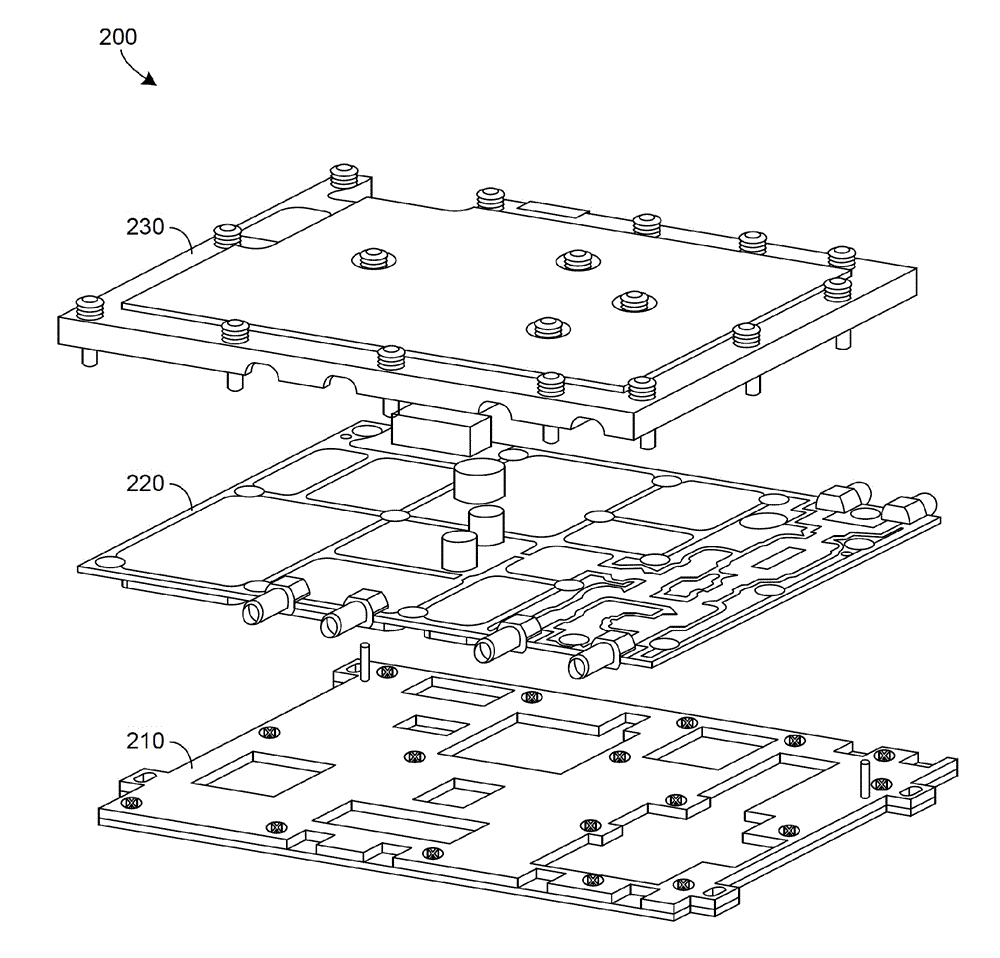

[0011] figure 2 An example of an assembly 200 suitable for housing electronic components in accordance with certain embodiments of the disclosed technology is illustrated. In an example, assembly 200 includes a printed circuit board (PCB) 220 positioned and secured between a top shield 230 and a laminated bottom shield 210 . Top shroud 230 may be machined or laminated.

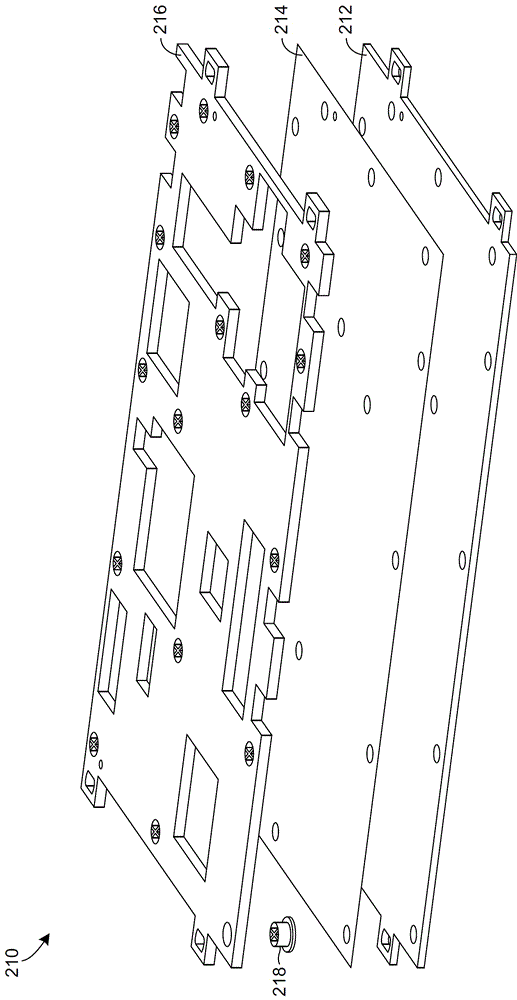

[0012] image 3 Illustrative of certain embodiments in accordance with the disclosed technology figure 2 A more detailed example of the stacked bottom shroud 210 is shown. In an example, the bottom shield 210 includes a conductive outer cover 212 that may be attached, for example, with a suitably constructed laminate material 214 such that the conductive outer cover 212 mates with the conductive punched wall section 216 . Mechanical hardware 218 may be sized to provide suitable spacing between conductive punched wall section 216 and PCB 220 such that the selected gasket material is not overly compressed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com