Inflatable fenders

A fender, inflatable technology, applied in the direction of yarn, application, boat construction, etc., can solve the problems of reduced tensile strength adhesion, deterioration, unpractical use, etc., to prevent the reduction of adhesion with rubber, prevent Effects of reduced tensile strength and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

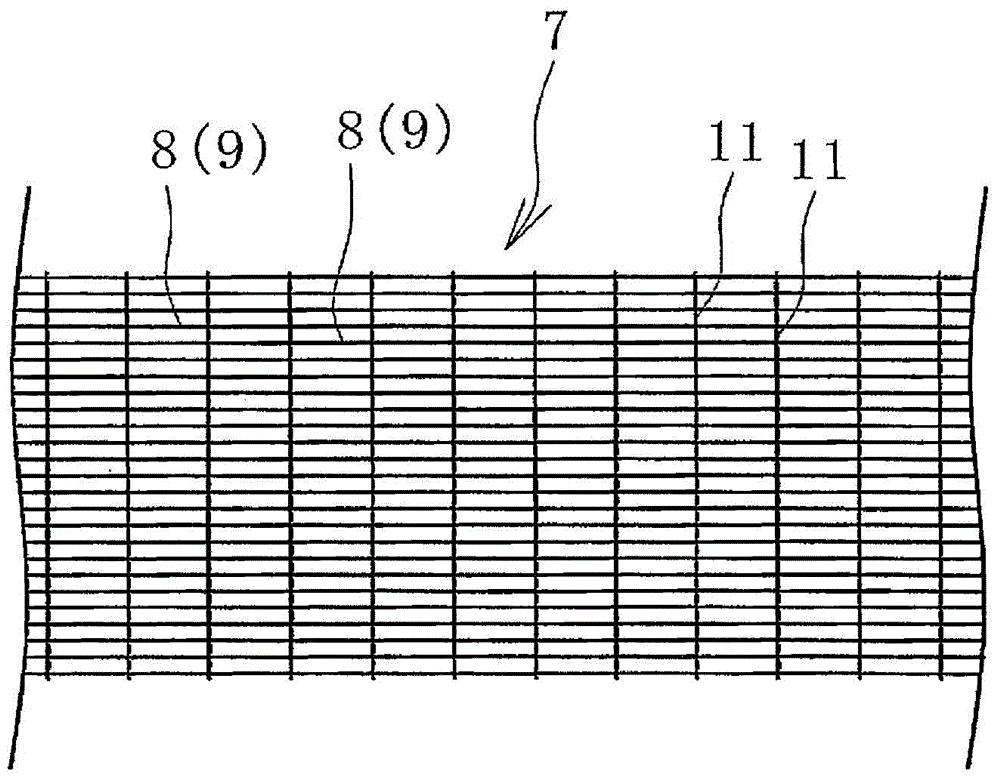

[0044] As shown in Table 1, the longitudinal wires constituting the fiber-reinforced layer have different twisted cord specifications, and various twisted cords are used to make 10 kinds of cord weaving structures (the weaving density of longitudinal wires is 50 pieces / 5cm, A fiber reinforced layer with a weaving density of 5 strands / cm). The twist coefficient K in Table 1 is as described above. The cord properties are values measured in accordance with JIS L1017.

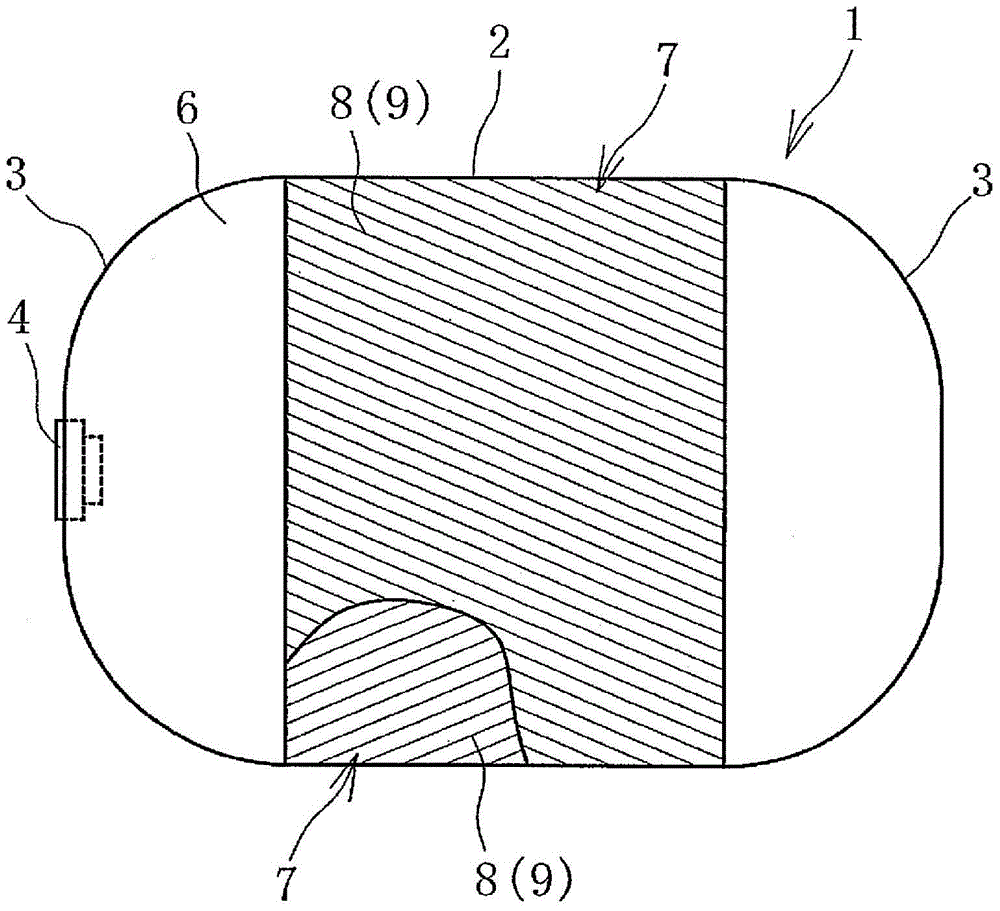

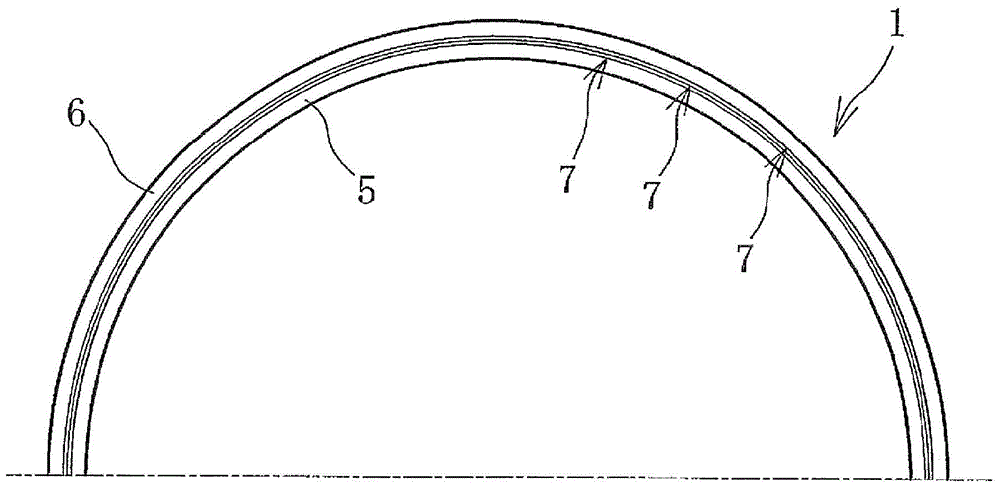

[0045] Using the fiber-reinforced layer produced, test samples of inflatable fenders (Examples 1-5, Comparative Examples 1-5) differing only in the fiber-reinforced layer were prepared, and the following destructive pressure test, fatigue resistance test, and hydrostatic test. The dimensions of the test sample were 3.3 m in outer diameter and 6.5 m in length, and the number of laminated fiber-reinforced layers was 6.

[0046] Moreover, the adhesion test with the following rubber was implemented about each (Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com