Automatic bamboo piece needle-threading machine

A technology of automatic threading and bamboo strips, applied in the field of needle threading machines, can solve the problem of not being able to thread bamboo strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

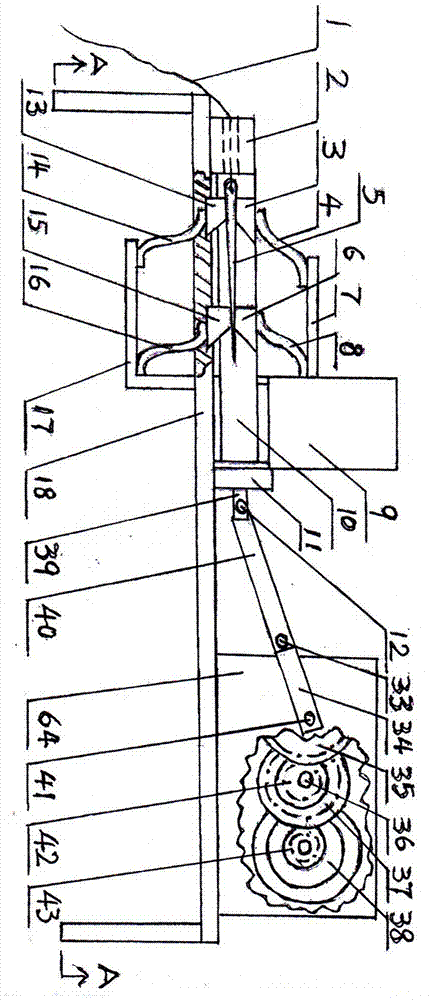

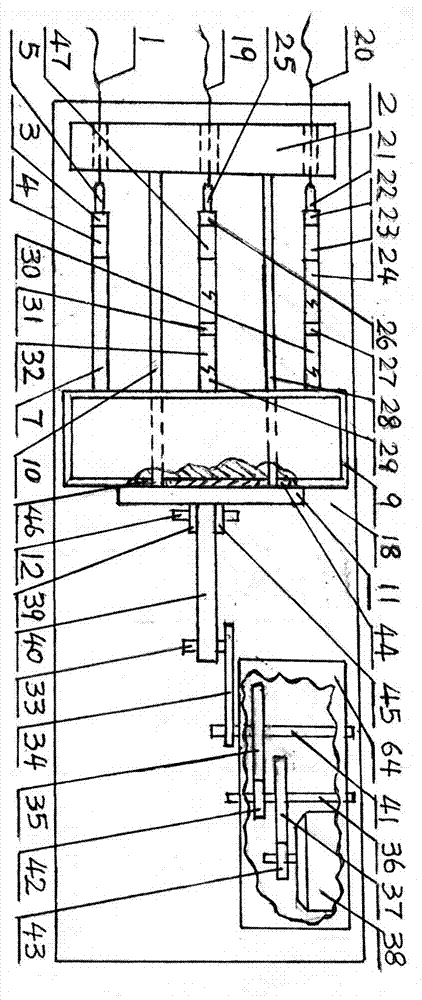

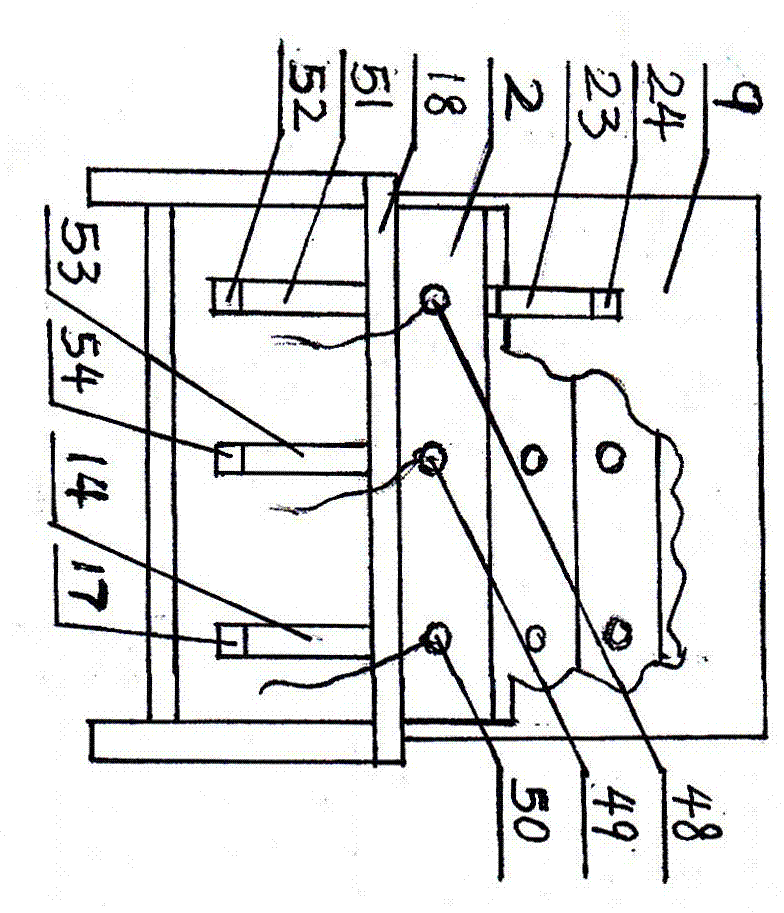

[0012] refer to Figure 1~4 , the bamboo needle threading machine consists of the first bamboo needle thread 1, the second bamboo needle thread 19, the third bamboo needle thread 20, bamboo 2, the first bamboo needle trapezoidal clip 3, the second bamboo needle Needle trapezoid clamp 6, the third bamboo needle trapezoid clamp 13, the fourth bamboo needle trapezoid clamp 15, the fifth bamboo needle trapezoid clamp 26, the sixth bamboo needle trapezoid clamp 31, the seventh bamboo slice Needle trapezoidal clamp 58, the eighth bamboo needle trapezoidal clamp 56, the ninth bamboo needle trapezoidal clamp 22, the tenth bamboo needle trapezoidal clamp 27, the eleventh bamboo needle trapezoidal clamp 62, the twelfth bamboo needle trapezoidal clamp Bamboo needle trapezoidal clip 61, the first S-shaped spring 4, the second S-shaped spring 8, the third S-shaped spring 14, the fourth S-shaped spring 16, the fifth S-shaped spring 47, the sixth S-shaped spring 32, The seventh S-shaped spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com