Anionic dye desalting ceramic composite membrane preparation method

An anionic dye, ceramic composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex preparation and low removal rate, and achieve simple process, good permeability, operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

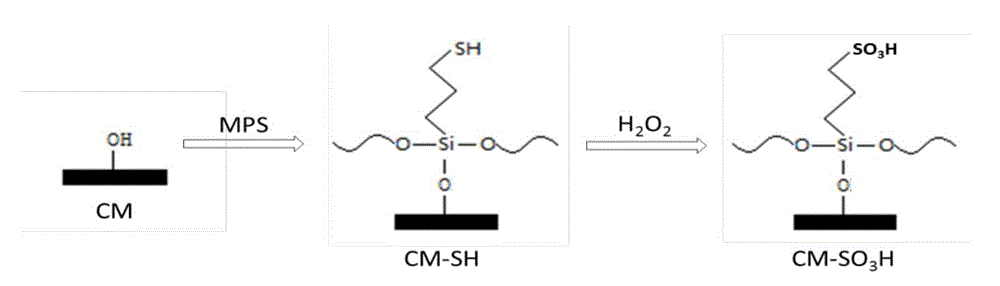

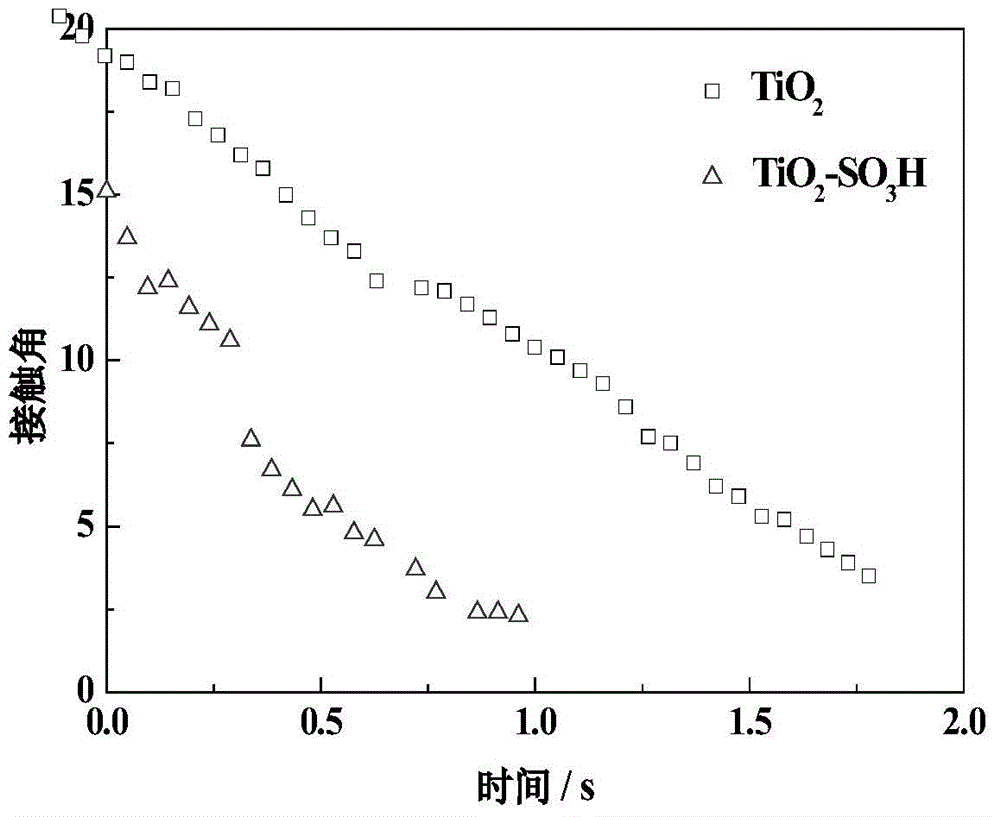

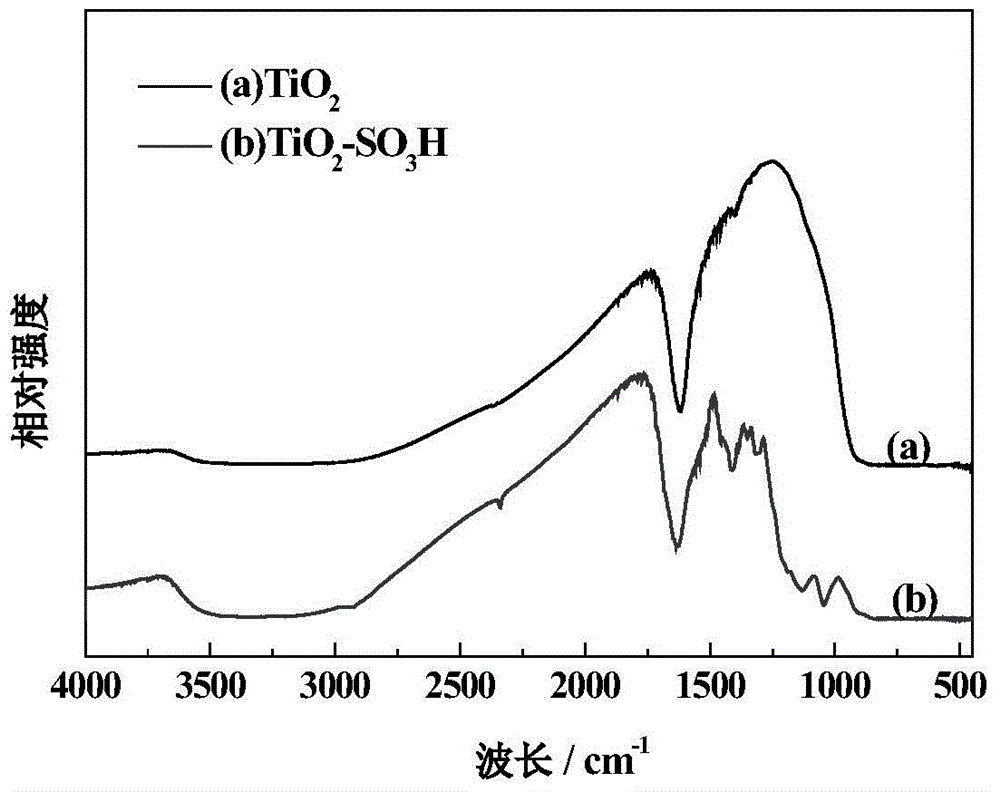

[0028] Step 1: Membrane tube pretreatment. Wash the tubular ceramic ultrafiltration membrane (titanium oxide single-tube membrane, its PEG molecular weight cut-off is 1800, and the pore size is 2.2nm), remove the impurities on the surface of the membrane and in the pores, and then dry it;

[0029] Step 2: Preparation of silane coupling agent solution. Dissolve (3-mercaptopropyl)trimethoxysilane in ethanol at a concentration of 0.05mol / L, add acetic acid as a hydrolysis catalyst, adjust the pH to 3.5, and mix and stir at room temperature;

[0030] Step 3: silanization reaction. Soak the pretreated tubular ceramic ultrafiltration membrane in the stirred reaction solution, take it out after reacting in a constant temperature oscillator at 35°C for 10 hours, and put it in an oven at 110°C to dry for 3 hours after cleaning;

[0031] Step 4: mercapto oxidation reaction. Soak the tubular ceramic ultrafiltration membrane in 4% hydrogen peroxide, oxidize it for 6 hours, take it out,...

Embodiment 2

[0038] Step 1: Membrane tube pretreatment. Wash the tubular ceramic ultrafiltration membrane (titanium oxide single-tube membrane, its PEG molecular weight cut-off is 2200, and the pore size is 2.4nm), remove the impurities on the surface of the membrane and in the pores, and then dry it;

[0039] Step 2: Preparation of silane coupling agent solution. Dissolve 2-mercaptoethyltriethoxysilane in ethanol at a concentration of 0.08mol / L, add hydrochloric acid as a hydrolysis catalyst, adjust the pH value to 4, and mix and stir at room temperature;

[0040] Step 3: silanization reaction. Soak the pretreated tubular ceramic ultrafiltration membrane in the stirred reaction solution, react in a constant temperature oscillator at 45°C for 10 hours, take it out, clean it and put it in an oven at 120°C to dry for 2 hours;

[0041] Step 4: mercapto oxidation reaction. Soak the tubular ceramic ultrafiltration membrane in 3% hydrogen peroxide, oxidize it for 9 hours, take it out, wash an...

Embodiment 3

[0046] Step 1: Membrane tube pretreatment. Wash the tubular ceramic ultrafiltration membrane (zirconia single-tube membrane, its PEG molecular weight cut-off is 1900, and the pore size is 2.3nm), and then dry it after removing impurities on the surface of the membrane and in the pores;

[0047] Step 2: Preparation of silane coupling agent solution. Dissolve (3-mercaptopropyl)trimethoxysilane in ethanol at a concentration of 0.06mol / L, add acetic acid as a hydrolysis catalyst, adjust the pH to 5, and mix and stir at room temperature;

[0048] Step 3: silanization reaction. Soak the pretreated tubular ceramic ultrafiltration membrane in the stirred reaction solution, react in a constant temperature oscillator at 60°C for 8 hours, take it out, and put it in an oven at 130°C to dry for 1 hour after cleaning;

[0049] Step 4: mercapto oxidation reaction. Soak the tubular ceramic ultrafiltration membrane in 3% hydrogen peroxide, oxidize it for 8 hours, take it out, wash and dry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com