Heat insulation wall tile

A technology of heat-insulating wall bricks and heat-insulating layers, applied in the field of building ceramics manufacturing, can solve problems such as environmental pollution, ineffective utilization, waste of resources, etc., to eliminate pollution, improve effective utilization, and have good sound and heat insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The following describes the present invention in further detail with reference to the examples of the drawings:

[0016] Such as figure 1 The illustrated embodiment 1 includes a thermal insulation layer 1 and a bottom layer 2, the thickness of the thermal insulation layer is 10 mm, and the thickness of the bottom layer is 4.2 mm.

[0017] The production method is:

[0018] A. Mix ceramic polishing waste residue, talcum mud, paper pulp waste liquid, and papermaking pool mud in a ratio of 1:1:1:1, pass through a 5000 mesh sieve, add active aluminum powder and hydrochloric acid, and foam at low temperature to a thickness of 10mm. Thermal insulation layer body;

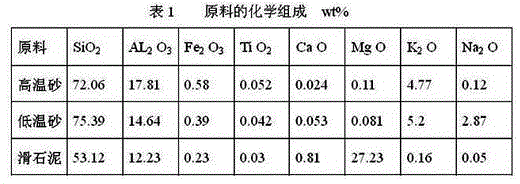

[0019] B. Add 5 tons of high temperature sand, 40 tons of low temperature sand, 15 tons of talc mud, 15 tons of ceramic polishing waste residue and 30% of the total amount of water to the ball mill in the ball mill. After the raw material is crushed through the 10,000 mesh sieve, Use a spray drying tower to spray the pow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap