Moulding machine

A molding machine and workbench technology, applied in the field of sand casting, can solve problems such as uneven sand pressing, poor working environment for workers, and reduce labor intensity, so as to improve the working environment, improve compactness and compaction efficiency, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

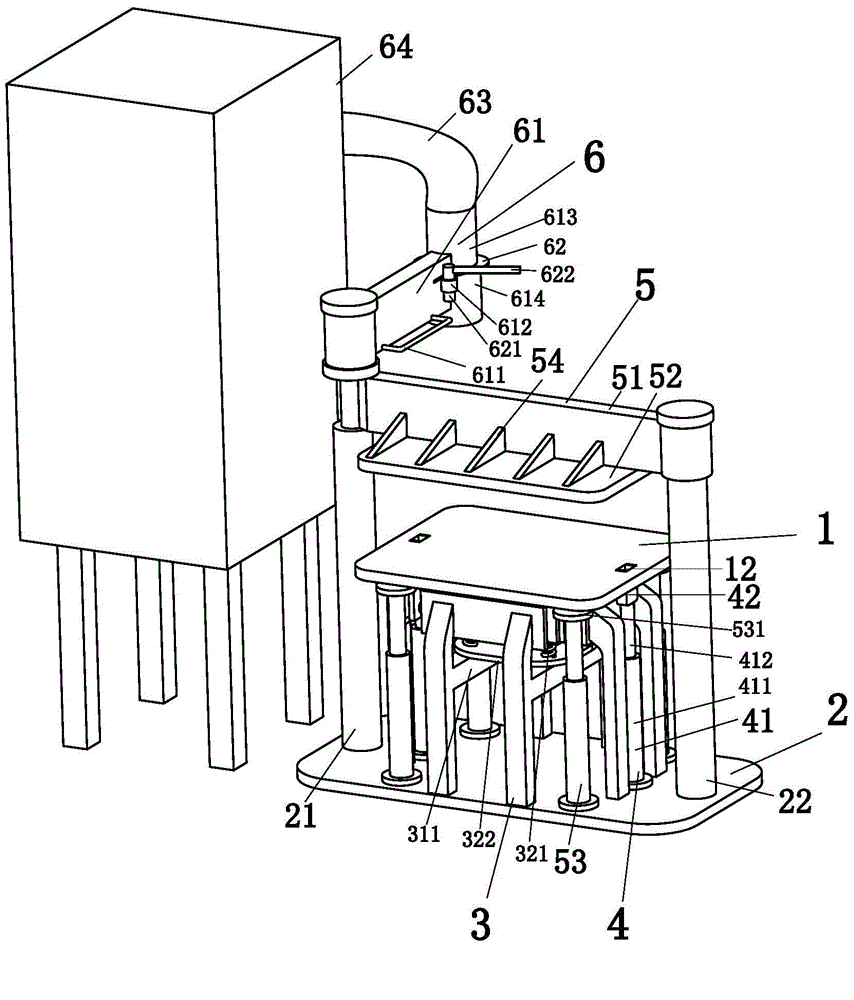

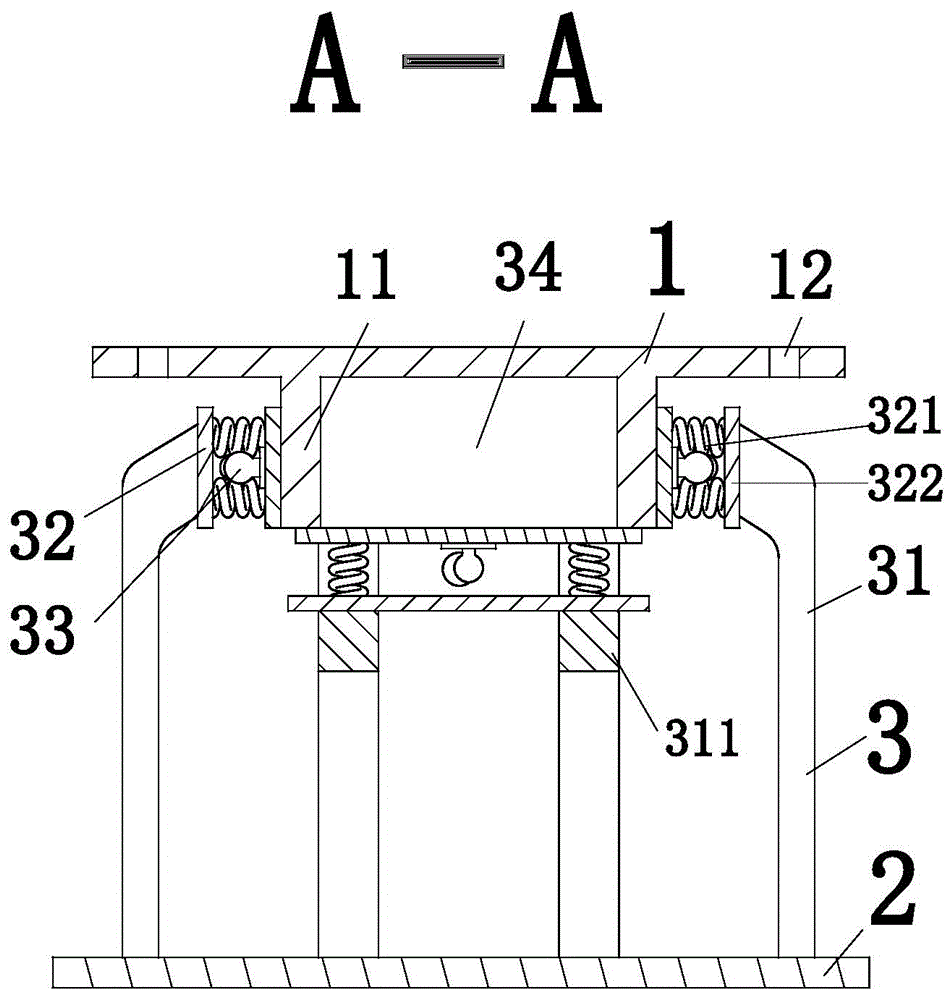

[0034] Such as Figure 1 to Figure 8 As shown, a molding machine according to the present invention includes a workbench 1, a bottom plate 2, a vibration device 3, a turning device 4, a sand pressing device 5, and a sand adding device 6. The workbench 1 is placed horizontally, and the workbench A hollow protrusion 11 is provided on the lower surface of 1, and the left and right sides of the workbench 1 are provided with through holes 12 symmetrically; the bottom plate 2 is located directly under the workbench 1, and the left and right sides of the bottom plate 2 are provided with left uprights symmetrically 21 and the right upright 22.

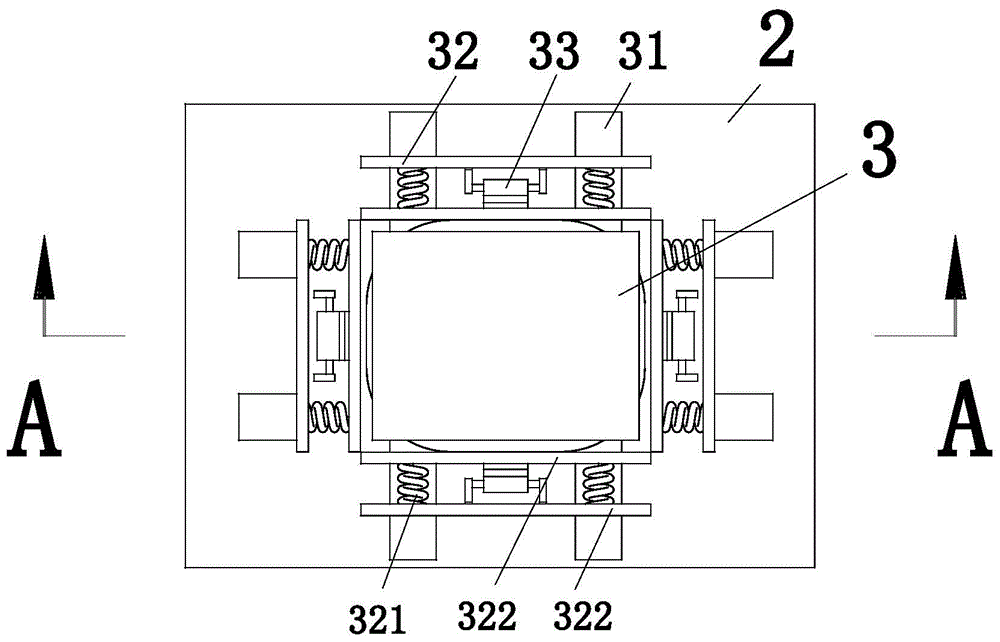

[0035] The vibration device 3 includes four brackets 31, a vibrating body 32, and five eccentric motors 33. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap