Efficient energy-saving multi-roller planet automatic seamless joint plastic refining double-purpose regeneration rubber device

A high-efficiency, energy-saving and reclaimed rubber technology, applied in the field of rubber refining equipment, can solve problems such as low degree of automation, large bending deformation, and impact on product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

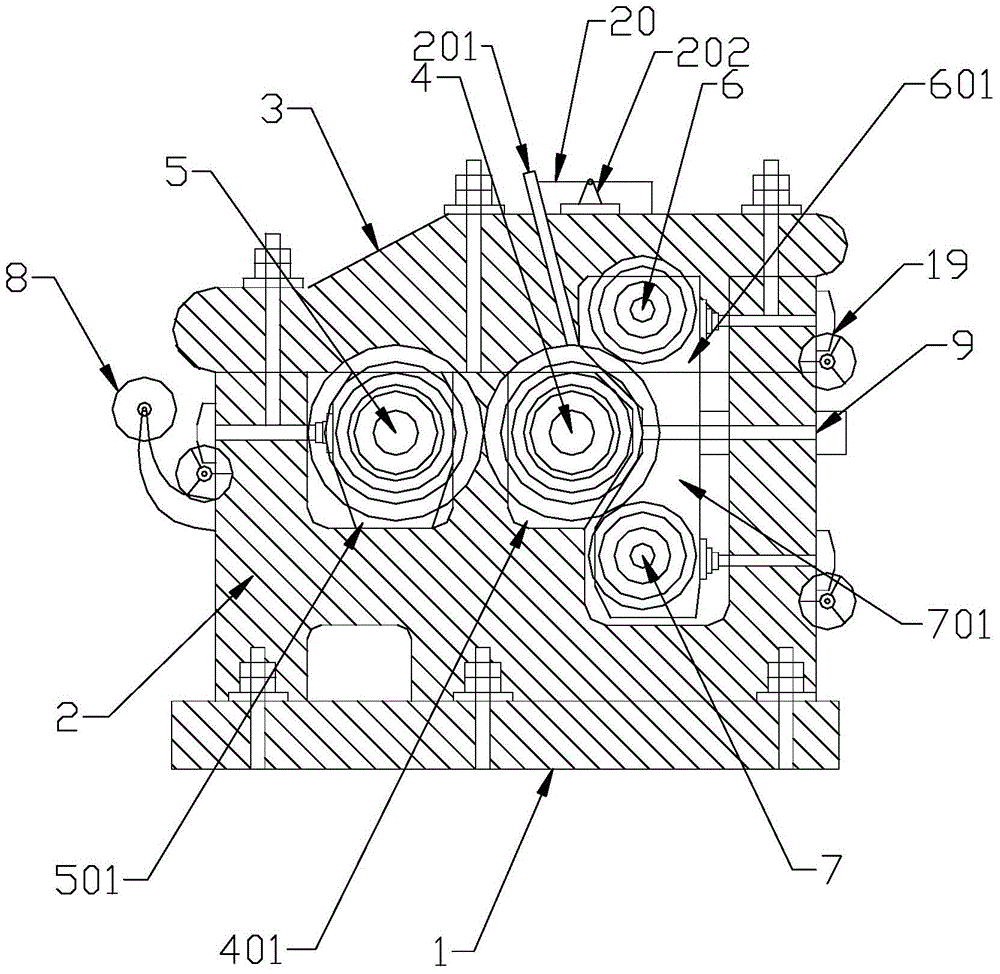

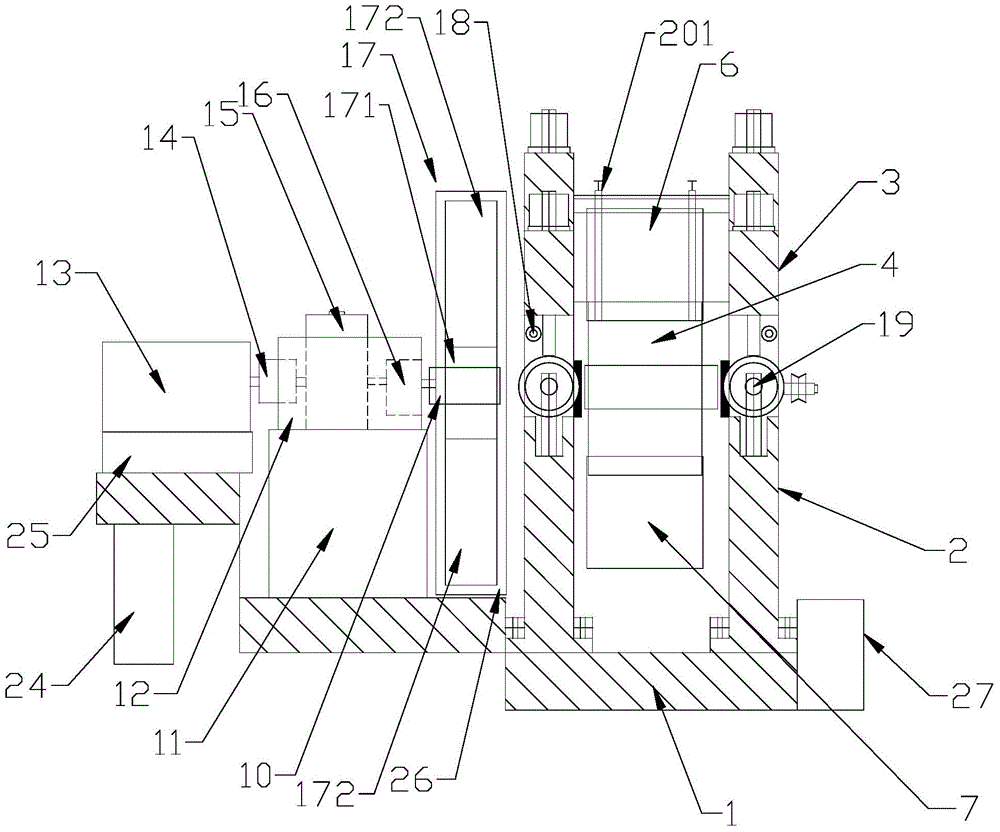

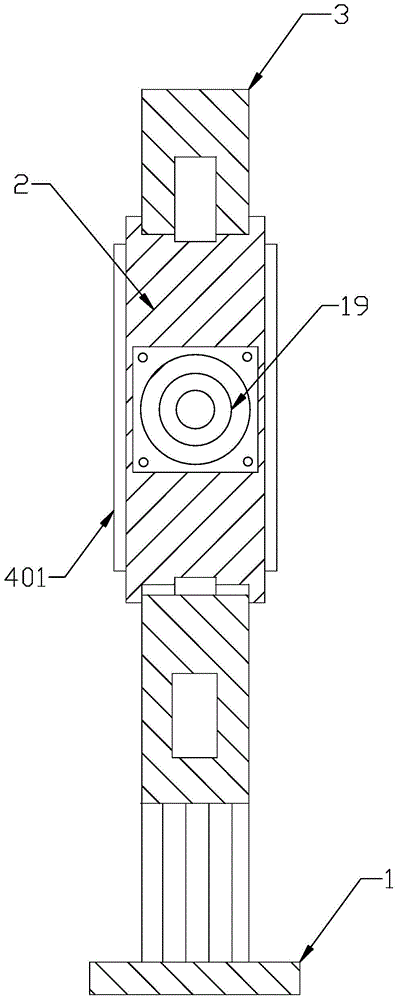

[0029] Such as Figure 1-4As shown, the high-efficiency and energy-saving multi-roller planetary automatic seamless butt joint plastic refining dual-purpose regenerated rubber device described in Embodiment 1 of the present invention includes an integral base chassis 1 and a stepped multi-adjustment stack symmetrically arranged on the integral base chassis 1 The peak frame 2 and the stepped frame gland 3 arranged on the above two stepped and multi-adjustable peak frame 2; the outer side of the integral base chassis 1 is provided with an electric control device 24, which saves expensive Inverter, the electronic control device adopts an electronic control device with an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com