Servo-actuated support head having magneto-rheological damping function

A technology of magnetorheological damping and support head, which is used in supports, manufacturing tools, vibration suppression adjustment and other directions to achieve the effect of suppressing flutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

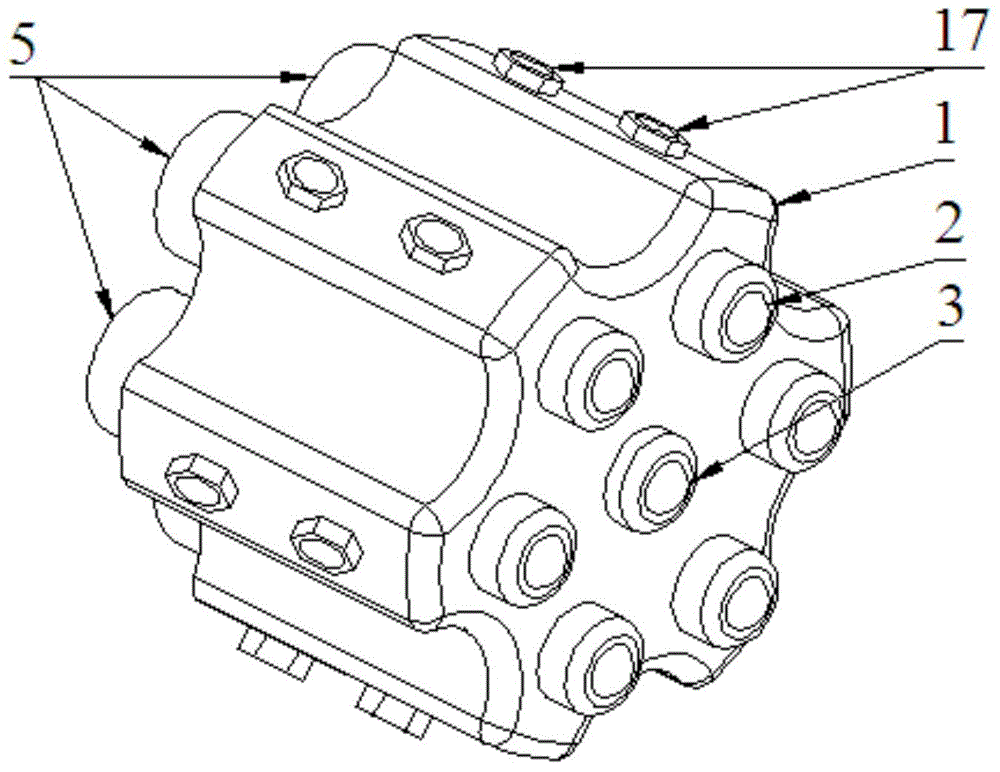

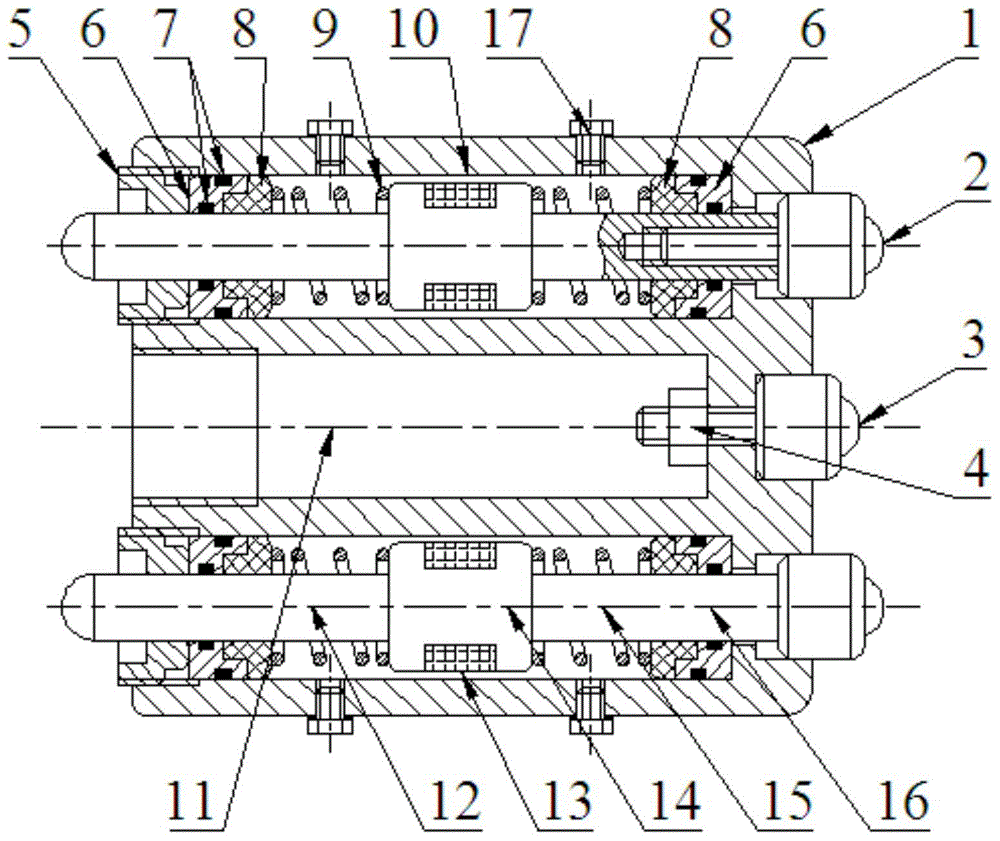

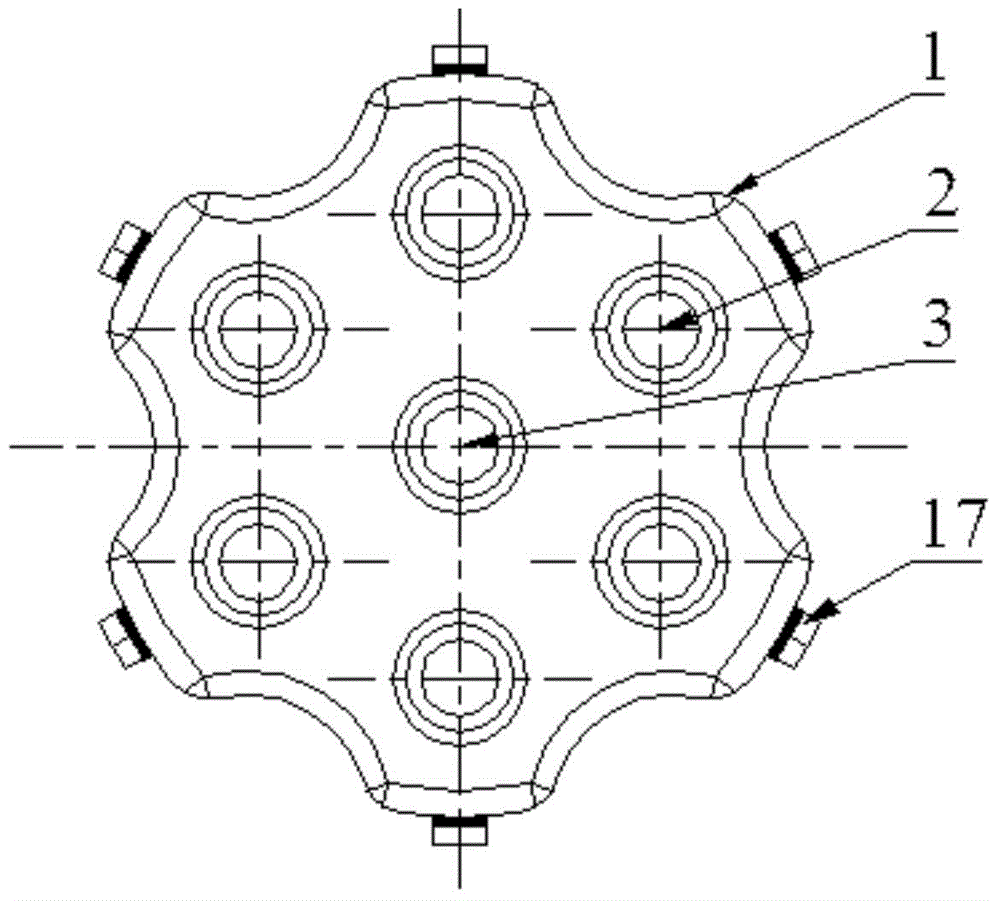

[0012] As shown in the accompanying drawings, the follow-up support head with magnetorheological damping function of the present invention includes a base 1, and a central stepped through hole 11 is opened at the middle position of the base, and the central stepped through hole 11 is opened in the middle of the base. Around the hole 11, there are a plurality of circumferential stepped through holes 10 whose axes are parallel to the axis of the central stepped through hole 11 along the same circumferential direction. There is an internal thread, and a magneto-rheological damper 16 is installed in each circumferential stepped through hole, and the magneto-rheological damper 16 includes a piston ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap